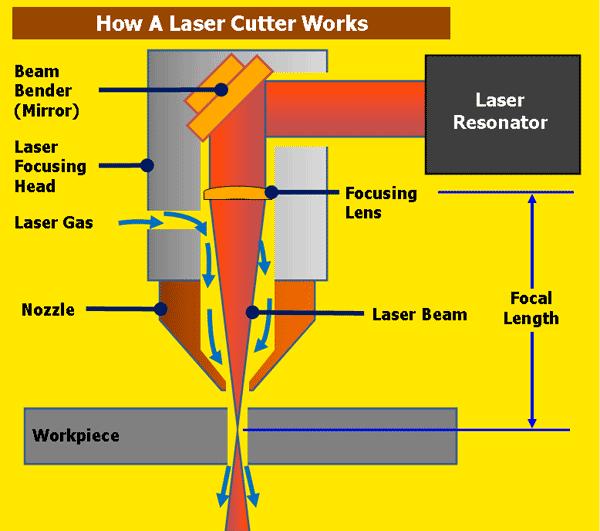

Laser cutting is an advanced processing technology that uses high-energy laser beams to cut various materials. The working principle of laser cutting is as follows:

1. Generation of laser

The core component of the laser cutting system is the laser. The resonator laser in the laser generates laser through a specific physical process. In this process, the medium such as laser gas is excited to produce a laser beam with high monochromaticity, coherence and high energy density.

2. Beam transmission

1)Beam guidance

The generated laser beam first passes through the beam bender (Mirror), which plays the role of guiding the direction of the beam and accurately guides the laser beam to the cutting area.

2)Focusing preparation

The laser beam then enters the focusing head (Focusing Head), where the laser beam begins to prepare for focusing.

3. Focusing cutting

1)Precise focusing

The laser gas lens (Laser Gas Lens) in the focusing head further focuses the laser beam to form a very small high-energy focus on the surface of the workpiece (Workpiece). The energy density at this focus is extremely high, which can instantly heat up the material and melt or vaporize it.

2)Cutting process

When the focus of the laser beam acts on the workpiece, the material is cut quickly at high temperature. The nozzle usually sprays auxiliary gas, such as oxygen, nitrogen, etc., to help blow away the melted or vaporized material, while preventing slag from accumulating in the cutting area, improving cutting quality and efficiency.

In short, laser cutting achieves efficient and precise cutting of various materials by precisely controlling the generation, transmission and focusing of high-energy laser beams. It has the advantages of high cutting accuracy, fast speed and small heat-affected zone, and has been widely used in industrial manufacturing, metal processing, electronic manufacturing and other fields.

ANTISHICNC hot-selling AT-3015 laser cutting machine

| Model | AT-3015 |

| Working Area | 3000mm×1500mm |

| X/Y/Z Travel | 3000/1500/150mm |

| Laser Wavelength | 1080nm |

| Laser Power | Raycus 1000W-12000W |

| Working Life of Fiber Source | More than 100000 hours |

| Laser Beam quality | <0.373mrad |

| Laser Cutting Head | Raytools Automatic Focus Laser |

| Position Type | Red Dot Pointer |

| Max. Idle Running Speed | 150M/min |

| Geometric Position Accuracy | Within ±0.05mm/M |

| Reorientation Accuracy | Within ±0.03mm/M |

| Lubrication System | Electrical Motored |

| Min. Line Width | ±0.02mm |

| Transmit system | Dual Rack & Pinion type |

| Auxiliary Gas for Cutting/Assist system | Oxygen, Nitrogen, Air/Germany SMC |

| Compatible Software | AutoCAD, CorelDraw, etc. |

| Handle Control | WIFI Wireless Control Handle |

| Graphic Format | DXF/PLT/AI |

| Power Supply Voltage | 380V/3Ph/50Hz |

| Warranty | 2 Years |

ANTISHICNC is a professional laser cutting equipment supplier. If you have similar needs, please click the link below to view related products,

contact contact@antsmachine.com

Keywords: laser cutting, laser working principle, metal cutting, fiber laser