The pipe bending machine uses the equipped mold (general or special mold) to bend the cold metal pipe into various geometric cross-sectional shapes. The bending machine generally uses a special CNC system for the bending machine. The coordinate axis of the bending machine has developed from a single axis to 12 axes. The CNC system can automatically realize the slider running depth control, slider left and right tilt adjustment, rear stopper front and back adjustment, left and right adjustment, pressure tonnage adjustment and slider approach working speed adjustment, etc. The bending machine can easily realize the actions of slider downward, inching, continuous, pressure holding, return and midway stop, and complete the bending of multiple elbows at the same angle or different angles at one time.

Introduction to the principle of pipe bending machine

The working principle of the pipe bending machine is to bend metal pipes into various shapes through the principles of electricity, hydraulic pressure, air pressure, etc. The main structure of the pipe bending machine includes a pipe bending machine frame, a bending head, a hydraulic system, an electrical control and other parts. During operation, put the metal pipe into the bending head, and manually or automatically rotate the bending head to the corresponding angle by operating the control button, and use hydraulic or air pressure to act on the mold on the workbench to bend the metal pipe. The bending head can achieve three-dimensional bending, which can make metal pipes form various complex shapes in space.

Main types of pipe bending machines

1.Hydraulic pipe bending machine: The working principle of the hydraulic pipe bending machine is to decompose the bending action, including hydraulic drive, clamping, unclamping, bending, bending, auxiliary feeding, auxiliary retreating, core feeding, core retreating and other actions. In the production of elbows, the action of the hydraulic pipe bending machine is automatic, but the feeding and three-dimensional rotation angle can only be determined by fixed length and angle positioning, which is generally done manually.

Hydraulic pipe bending machines are usually composed of oil tanks, pump stations, circuit systems and pipe bending devices. When pipe bending is required, the metal pipe is first fixed on the pipe bending device, and the parameters such as the bending angle and radius are adjusted. Then the motor is started to drive the pump station, and the pump station begins to inject liquid pressure oil into the oil cylinder. By controlling the pressure and flow of the hydraulic system, the shape and angle of the bent pipe can be accurately controlled to achieve high-precision processing.

2.CNC pipe bending machine: CNC pipe bending machine uses servo motor instead of hydraulic drive, which can control feed and retreat, rotation of inclination angle and bending of elbow, auxiliary feed and retreat, lifting and lowering of machine head, etc. Although clamping annealing, core feeding and core pushing are still completed by hydraulic drive, CNC pipe bending machine provides higher precision and efficiency.

CNC pipe bending machine mainly uses computer digital control system to accurately control the bending action of pipe. It first inputs the required bending parameters, such as bending angle, radius, etc. into the CNC system. Then, the system controls the driving components such as motor and hydraulic system according to these parameters, so that the pipe bending mold bends the pipe according to the set trajectory and requirements. During the bending process, various sensors will monitor and feedback information in real time to ensure the accuracy and quality of the bending.

3.Fully automatic pipe bending machine: Fully automatic pipe bending machine is an automation equipment that integrates electromechanical hydraulic system. The automatic pipe bending machine control system composed of servo motor and its motion control unit PLC and touch screen can process different workpieces efficiently.

Pipe bending machine process plan

1.Preparation work

Select the appropriate pipe bending machine model and mold according to the pipe material, pipe diameter and bending requirements.

Check whether the pipe bending machine equipment is in normal condition.

Clean the surface of the pipe and remove oil, rust, etc.

2.Pipe clamping

Place the pipe accurately in the pipe bending machine fixture to ensure firmness and precise position.

3.Parameter setting

Set appropriate bending speed, force and other parameters according to the requirements of pipe specifications and bending angles.

4.Bending operation

Start the pipe bending machine and bend slowly, paying attention to the deformation of the pipe.

Control the feed speed during the bending process to avoid wrinkling, rupture and other problems of the pipe.

5.Quality inspection

After bending, check whether the bending angle, roundness, surface quality, etc. meet the requirements.

For the parts that do not meet the requirements, analyze the reasons and make adjustments before re-bending.

6.Subsequent processing

Carry out necessary cleaning and sorting for the qualified pipes.

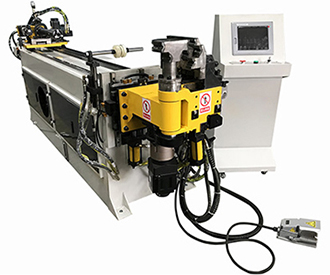

ANTISHI Single-Head Hydraulic Pipe Bending Machine DW130NC.

High speed single head hydraulic pipe bending machineuse microcomputer control, multi-group program, multi-angle setting, so that the operation is simple and convenient.

Man-machine dialogue operation, you can choose manual, half cycle, full cycle operation mode.

Adopt high-performance imported hydraulic valves and electrical components.

Equipped with large capacity cooling system, effectively control the working temperature.

The machine has the characteristics of easy operation, stable performance, high efficiency, high safety factor,whichis the ideal equipment for pipe fitting processing industry.

You can choose manualor semi-automatic operation mode. The movable foot switch has two functions: start and stop.

If you want to know more about pipe bending machine processing, please contact Shanghai Antishi Machine Equipment Co., Ltd. We provide customers with timely technical support, training and spare parts supply!