Part 1: Technical parameter

Specification of cutting steel pipe

| Cutable Material Type | Round tube,Square tube,Rectangular tube,Channel steel,Angle steel H shape steel |

| Fiber cutting tube wall thickness | Max20mm quality 16mm or less |

| cut material length | 12000mm |

| Diagonal Section | 30-800mm |

| Overall body length | 14000mm |

| Overall length of the machine | 16000mm |

| equipment weight | 8000KG |

| positioning accuracy | 0.05-0.1mm |

| Cutting accuracy | 0.5mm |

Cutting speed

| Max cutting speed | 30m/min |

The positioning accuracy of cutting torch movement is less than or equal to ±0.03mm; the positioning accuracy of busbar is less than or equal to ±0.03mm; the positioning accuracy of inclined mouth is ±0.05°

Equipment basic specifications

| No. | Name | Model | Manufacturer |

| 1 | Electrical control cabinet | ZLQ-XGEC | EOE-HZH |

| 2 | laser | 6000W | The Max |

| 3 | CNC pipe cutting system | EOE-HZH | EOE-HZH |

| 4 | bed composition | Double bottom beam design 14m | EOE-HZH |

| 5 | Servo drives and motors | 1.0KW | EOE Pure Servo motor |

| 6 | Front and rear chuck motors | 1.0KW | EOE Pure Servo motor |

| 7 | Rack thickness | 6mm base/8mm X beam | EOE-HZH |

| 8 | X Z axis motor | 400W | Passonic servo motor |

| 9 | Y-axis motor | 750W | EOEservo motor |

| 10 | reducer | 40:1 | EOE |

| 11 | Spin chuck | Diagonal 30-800mm | EOE-HZH |

| 12 | front chuck | Manual double-action design self-centering | EOE-HZH |

| 13 | rear chuck | Pneumatic single-acting design self-centering | EOE-HZH |

| 14 | laser head | 1 set | Raytool |

| 15 | Machine head gantry | 1set | EOE-HZH |

| 16 | train track | 14 sets (2m/set) | EOE-HZH |

| 17 | Heavy-Duty Front Catcher Unit | 2 sets,with buffing | EOE-HZH |

| 18 | Heavy-duty intermediate support system | 1 set,with buffing | EOE-HZH |

| 19 | cable | Heat resistance grade PE-7, plus shield | EOE-HZH |

| 20 | computer | Industrial control high and low temperature computer | EOE-HZH |

| 21 | Distribution box | Add two more cooling treatments | EOE-HZH |

| 22 | Move the wheel | Increased anti-wear and anti-warping design | EOE-HZH |

| 23 | chiller | 6000w | HAN LI |

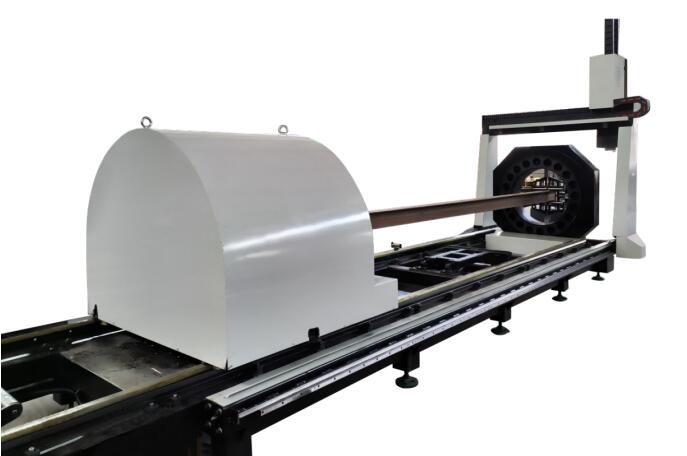

Part 2 : Product reference picture

Part 3 : Equipment Introductions

This machine is used for cutting metal round and square tubes, channel steel, angle steel, H shape steel etc. It adopts a 19-inch high-resolution LCD color display, which can display cutting graphics and cutting running tracks. Cutting programs can be edited manually. It adopts five-axis perfect cutting, which can cut round pipe, square pipe, channel steel and angle steel H shape steel . In addition, it supports functions such as pause, forward, backward, and speed regulation during processing. It can store 200G files and can be used at will. It is driven by high-efficiency servo motor, with fast speed, high efficiency, high precision and stable operation. High-flexible shielded wire is used to truly resist high-frequency interference. It is suitable for various fiber optic models. The movable beam can save tailings. The front chuck is equipped with two sets of intelligent follow-up splicing devices to facilitate the For long material processing requirements, there is a set of intelligent follow-up material support systems in between, so as to avoid Buyer’s long material sagging and affecting the cutting accuracy.

Samples Picture:

Feature

Control system features

1.Hardware board interpolation, stable and reliable, simple wiring

2.Support manual box operation, improve production efficiency

3.You can use the file to set the speed, or use the system to set the speed

4.File speed setting supports line speed and synthesis speed

5.The power clamp displays the maximum size of the processing graphics, which is intuitive and convenient

6.Graphics can be zoomed in and out

7.The limit can be used as the zero return switch, which is simple and convenient.

8.The starting position of processing is simple, no need to consider the pendulum axis

9.During processing, it can move forward and backward, and can be offset and returned

10.Parameter backup and parameter restoration.

11.Optional hole to start cutting, convenient and fast.

System performance parameters

Control accuracy: up to ±0.05mm

Maximum running speed: 30000mm/min

Electricity consumption

| Name | Electricity consumption(KW) | Total |

| Laser source | 6 |

20 KW/H |

| Lathe | 8 | |

| Water chiller | 6 |

Customer site conditions at the machine tool installation site (prepared by the customer before the arrival of the equipment)

| No. | Description |

| 1 | Installation site cement foundation |

| 2 | Power supply capacity:no less than 25 KVA |

| 3 | Power requirements:

1)3X380v±10%/60HZ,220v±10%/60hz Three-phase voltage stability is less than±5% Three-phase power unbalance is less than2.5% If the above power requirements are not met, it is recommended to use a regulated power supply Note: The power supply voltage is not allowed to have a sudden jump and a sudden power failure, otherwise it will easily cause damage to the equipment, the numerical control system and the laser. It must be well grounded (the grounding resistance is less than 10 ohms)) |

| 4 | Compressed air supply requirements:

1) Air supply capacity: 1.2 cubic meters per minute 2) Air supply pressure: 8.3 kg/cm² 3) The dew point temperature is not higher than 5 degrees Celsius: oil content ≤ 0.003ppm, fixed particles ≤ 0.01 microns It is recommended to use an oil-free air compressor, a freeze dryer and a precision filter (the system must not have rusted components), and an air storage tank can be added if possible. |

| 5 | Laser working gas and auxiliary gas for cutting:

1) Working gas: air, oxygen, nitrogen |

| 6 | Cut pipe: smooth, flat, rolled evenly, ellipse deviation does not exceed 5mm diameter, up to ISO standard |

| 7 | Installation site foundation requirements: seismic grade 6. If there is a large earthquake source near the machine tool, it is recommended that the purchaser build a vibration isolation trench when making the foundation. |

| 8 | CNC cutting machine installation site and environmental requirements:

Temperature requirements: -10-55℃ 2) Humidity requirements: <90% non-condensing |

| 9 | Requirements for the use of cooling liquid by the chiller: The buyer must comply with the cooling liquid requirements for the chiller proposed by the supplier (supplier), and do not use the cooling liquid used by the supplier, which will cause the cooling water pipes of the chiller to freeze, which will further lead to equipment damage. Party is not responsible for the warranty. |

| 10 | Equipment operators should have high school or technical secondary school education level or above, and should have experience in operating computers and general CNC machine tools, and the equipment should be equipped with a programming computer |

Machine acceptance requirements:

The foundation of the whole machine should meet the basic installation requirements.

There is no major shock source around the machine.

All welding seams of the machine shall not have welding defects such as cracks, pores, and slag inclusions.

All moving parts of the machine must not be loose or stuck.

All terminals and components in the electrical box must not be loose.

Check whether all safety protection devices work sensitively and reliably.

Check that there is no leakage in all air supply lines (soap liquid inspection method)

Machine grounding must be good

Tools with the machine

| No. | Model | Quantity | Unit |

| 1 | M4 allen key | 1 | pc |

| 2 | M4 allen key | 1 | pc |

| 3 | M4 allen key | 1 | pc |

| 4 | M4 allen key | 1 | pc |

| 5 | M4 allen key | 1 | pc |

| 6 | M4 allen key | 1 | pc |

| 7 | 6”Slotted screwdriver | 1 | pc |

| 8 | 6”Phillips screwdriver | 1 | pc |

| 9 | 12”adjustable wrench | 1 | pc |

| 10 | 8”adjustable wrench | 1 | pc |

| 11 | through needle | 1 | pc |

| 12 | nozzle | 100 | pcs |

| 13 | Protect lens | 10 | pcs |