| Item | Specifications |

| Table Size | 800×400mm |

| Max Vertical Travel of Long | 850mm |

| Max Vertical Travel of Cross | 430mm |

| Max Vertical Travel of Grinding Head | 540mm |

| Max Loading Capacity | 550Kg |

| Number of T-slot | 14X3mm/n |

| Table Speed | 5-25m/min |

| Longitudinal Handwheel Movement | 0.02mm/grid 5mm/r |

| Longitudinal Automatic Handwheel Movement | 0.1-10mm |

| Longitudinal Movement Rapid Speed | 50HZ 790mm/min |

| Grinding Wheel Dim | 350X40X127mm |

| Smindle Speed | 2800/3600r/min |

| Max Up and Down Movement | 500mm |

| Up and Down Handwheel Movement Up and Down Rapid Movement | 0.001/grid 0.2mm/r 630mm/min |

| Speed Spindle Motor | 5.5KW |

| Up and Down Motor | 90W |

| Longitudinal Motor | 120W |

| Oil Pump Motor | 2.2KW |

| Machine Height | 1980mm |

| Area covered | 2300X3850mm |

| Net Weight | 2700kg |

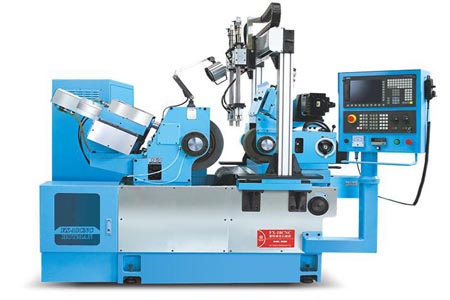

Application and performance characteristics of machine tools

1.1. This product is a mobile surface grinder with a trolley, which mainly uses the periphery of the grinding wheel to grind the surface of the workpiece and the end surface of the grinding wheel to grind the vertical surface of the workpiece.

1.2. Machine tool structure

This machine adopts a mobile trolley layout, which is composed of a bed, a column, a trolley, a grinding head, and a worktable. The bed and trolley adopt double V-shaped guide rails, and the trolley and worktable adopt one flat and one V-shaped guide rail. The frame moves horizontally along the bed, the workbench moves longitudinally along the guide rails on the frame, and the workbench guide rails are pasted with PTFE tape. The column is a steel-inlaid rectangular guide rail with six contact surfaces, which has good wear resistance, rigidity and movement sensitivity.

1.3. Grinding head

The main drive of the grinding head adopts an AC motor to drive the grinding wheel spindle to rotate. The spindle axis of the grinding head is parallel and fixed along the Y axis.

1.4. Longitudinal movement of the worktable

The longitudinal movement of the worktable is driven by hydraulic pressure. The direction valve of Taiwan grinder is used to control the single-rod bidirectional hydraulic cylinder with stepless speed regulation, which can promote the left and right movement of the worktable. Smooth movement, 3M slow speed does not crawl, easy to operate the knife.

1.5. The carriage moves laterally

The horizontal movement of the trolley adopts a ball screw driven by an AC motor to realize the functions of horizontal continuous, intermittent feed, micro feed (special configuration) and stepless speed regulation. The hand wheel is used to realize the tool setting function and the micro-feed function, which is convenient for bevel grinding.

1.6. Vertical movement of the grinding head

The vertical movement of the grinding head uses an AC motor to drive Taiwan’s precision T-shaped screw to achieve micro-feed (special configuration) and stepless speed regulation, and the handwheel to achieve tool setting and micro-feed functions.