Automotive interior system is an important part of the car body, the design workload of the interior system accounts for more than 60% of the workload of the whole car styling design, far more than the car shape, is one of the most important parts of the car body, each OEM is usually equipped with a large automotive interior design team. Each OEM usually has a large interior design team. This part of the parts is not only decorative, but the functionality, safety, and engineering attributes they involve are very rich and important.

What subsystems of automotive interiors require hydraulic presses?

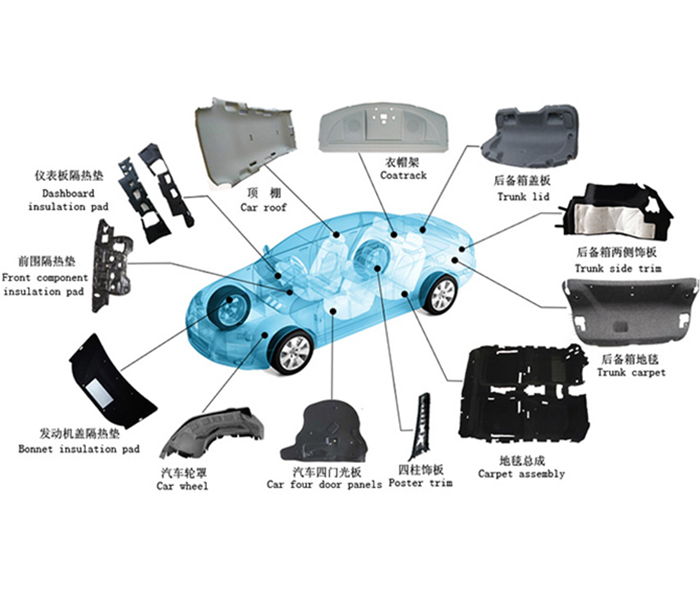

The roof system, the rest of the cab interior parts system, the luggage compartment interior parts system, the engine compartment interior parts system, the carpet and the luggage compartment are all molded with hydraulic presses.

Automotive interior molding materials are more, but the hydraulic molding materials, automotive interior molding process several mainstream processes, there are mainly the following categories:

| Materials for Hydroforming | Automotive interior molding process several mainstream processes |

|

1. Thermoplastic materials (ABS, PP, TPO, etc.) 2. Thermosetting materials (phenolic resins) 3. leather, artificial leather 4. Modified thermoplastic board materials (PP wood flour board, thermal PU board type) 5. rubber (NBR, EPDM, etc.) 6. Composite foam (EPP+TPO, PVC microfoam, PU foam sheet) |

1.Injection molding 2.Blow molding 3.Molded skin molding 4.Blister molding 5.Heat compression molding 6.Foaming process 7.Trimming process 8.Other processes, (coating, thermal bonding, etc.) |

Among them, hydraulic presses are used for hot pressing and laminating, foaming processes, trimming processes, and other processes (finishing, laminating, etc.).

The automotive interior molding press series is designed for the automotive interior parts industry, suitable for automotive interior decorative products such as headliner, carpet, heat insulation material, instrument panel, inner door panel, armrests, etc. hot press molding and cutting edge and other processes.

The structure is simple, but for different interior materials pressing process is different, the press put forward such as heating, exhaust and other ancillary requirements. According to the process requirements, it can be followed by the heating system, automatic loading and unloading device, raw material oven and pumping equipment to form an automated production line.

The tonnage of the interior trim press is mostly below 600T, generally the transverse table is larger, and the precision requirement is lower than that of the metal parts press Most of the presses adopt the host structure of integral frame type and split combination frame.

ANTISHICNC the current are in accordance with the customer’s customized needs to do: equipment structure: single-column presses, four-column presses, gantry structure presses, integral frame presses, combined frame presses. Tonnage: 20T-630T, free choice.

If you have the need of hydraulic press, welcome to contact Shanghai ANTISHICNC team, we will have a person to dock and answer your questions.

Please visit our official website: www.antsmachine.com

Or send email to: contact@antsmachine.com

Keywords: automotive interior molding, hot press laminating synthetic type, combination frame press, integral frame press, four column press.