For decades, it has been widely believed that five-axis CNC machining technology is the only way to process continuous, smooth, and complex curved surfaces. Once people encounter unsolvable problems in the design and manufacture of complex curved surfaces, they will turn to five-axis machining technology.

However, five-axis linkage CNC is the most difficult and widely used technology in CNC technology. It integrates computer control, high-performance servo drive and precision machining technology, and is used in the efficient, precise and automated machining of complex curved surfaces. Internationally, the five-axis linkage numerical control technology is regarded as a symbol of the automation technology level of a country’s production equipment. Because of its special status, especially its important influence on aviation, aerospace, military industry, and technical complexity, western industrialized countries have always implemented the export license system for the five-axis CNC system as a strategic material.

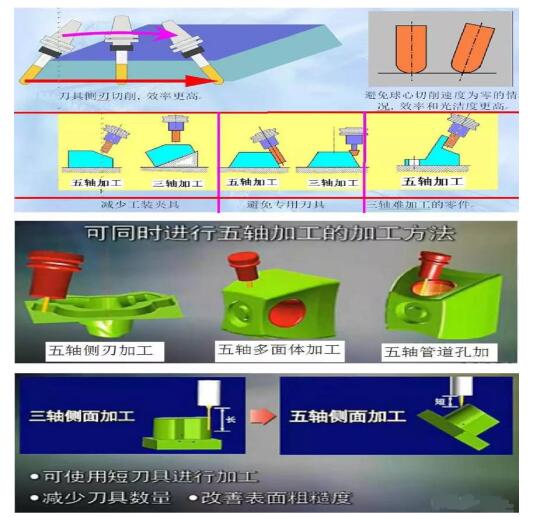

Compared with three-axis CNC machining, from the perspective of technology and programming, five-axis CNC machining for complex curved surfaces has the following advantages:

1) Improve processing quality and efficiency

2) Expand the scope of the process

3) Meet the new direction of composite development

However, due to interference and position control of the tool in the machining space, five-axis CNC machining has a much more complicated CNC programming, CNC system and machine tool structure than a three-axis machine tool. Therefore, the five-axis is easy to say, but it is really difficult to realize it! In addition, it is more difficult to operate well!

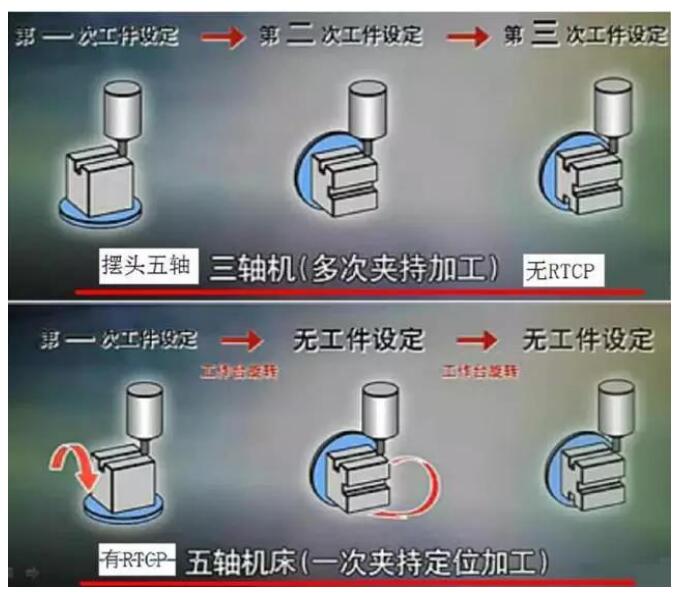

Speaking of five-axis, do you have to talk about the true and false five-axis? The difference between true and false 5-axis is mainly whether there is RTCP function.

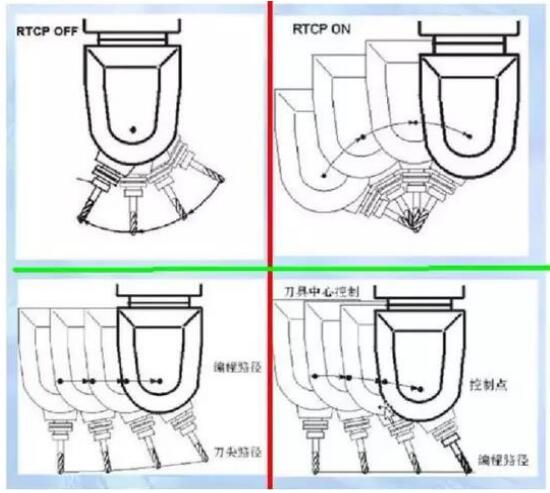

RTCP, explain, Fidia’s RTCP is the abbreviation of “Rotational Tool Center Point”, literally means “rotating tool center”, the industry tends to slightly escape it as “turn around the tool center”, and some people literally translate it as “rotating tool” Central programming”, in fact, this is only the result of RTCP. The RTCP of PA is the abbreviation of the first few words of “Real-time Tool Center Point rotation”. Heidenhain refers to the similar so-called upgrade technology as TCPM, which is the abbreviation of “Tool Centre Point Management”, tool center point management. Other manufacturers call the similar technology TCPC, which is the abbreviation of “Tool Center Point Control”, which is the tool center point control. To

From the literal meaning of Fidia’s RTCP, assuming that the RTCP function is executed manually, the tool center point and the actual contact point between the tool and the workpiece surface will remain unchanged. At this time, the tool center point falls at the actual contact point between the tool and the workpiece surface. The tool holder will rotate around the tool center point. For ball-end tools, the tool center point is the target track point of the CNC code.

In order to achieve the purpose of allowing the tool holder to simply rotate around the target trajectory point (ie the tool center point) when executing the RTCP function, it is necessary to compensate for the offset of the linear coordinates of the tool center point caused by the rotation of the tool holder in real time. It can change the angle between the tool holder and the normal at the actual contact point of the tool and the workpiece surface while keeping the tool center point and the actual contact point of the tool and the workpiece surface unchanged, so as to play the best cutting of the ball nose tool. Efficiency, and effectively avoid interference and other effects. Therefore, RTCP seems to be more standing on the tool center point (that is, the target trajectory point of the numerical control code) to deal with the change of the rotation coordinate. To

Five-axis machine tools and numerical control systems that do not have RTCP must rely on CAM programming and post-processing, and plan the tool path in advance. For the same part, if the machine tool is changed, or the tool is changed, CAM programming and subsequent processing must be performed again. It is called fake five-axis, and many domestic five-axis CNC machine tools and systems belong to this kind of fake five-axis.

In short, the true five-axis is five-axis and five-linkage, the fake five-axis may be five-axis and three-linkage, and the other two axes only play a positioning function!

This is a popular saying, not a standard one. Generally speaking, five-axis machine tools are divided into two types: one is five-axis linkage, that is, all five axes can be linked at the same time, and the other is five-axis positioning processing. It is a five-axis three-linkage: that is, two rotating shafts are rotated and positioned, and only three axes can be simultaneously processed. This five-axis machine tool commonly known as 3+2 mode can also be understood as a fake five-axis.