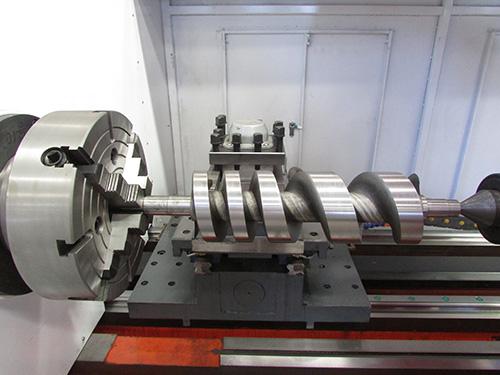

The CNC whirlwind milling machine not only has high production efficiency, but also because it does not use difficult-to-handle cutting fluid, the “comma”-shaped chips are easy to recycle, and the environmental pollution of the production plant is much lower than that of general milling. It is an efficient green manufacturing technology worth promoting. The new generation of CNC whirlwind milling has multiple functions such as rotary milling, circumferential milling, turning, grinding, and polishing. CNC whirlwind milling is installed on CNC lathes and other lathes by domestic users. The processing efficiency of single-head multi-head, worm, screw, nut and other threaded products is increased by 10-30 times, the processing accuracy is improved, and the finish is 0.8um ;

Cyclone milling can realize dry cutting, heavy-duty cutting, difficult-to-machine materials and ultra-high-speed cutting, and consumes little power. The surface roughness can reachRa0.8μm. The spindle speed of the lathe is slow, so the machine has high motion accuracy and good dynamic stability. It is an advanced thread processing method. It is widely used in woodworking machinery and equipment, oil drilling industry, reducer industry, mold industry, automation industry, auto parts industry and other major industries.

A CNC milling machine is an automated machine tool equipped with a program control system. The control system can logically process the program with control codes or other symbolic instructions, and decode it, so that the machine tool can operate the CNC bending machine and process the parts.

The machine tool body of CNC whirlwind milling is similar to traditional machine tools. It consists of a spindle drive device, a feed drive device, a bed, a table, and auxiliary motion devices, a hydraulic pneumatic system, a lubrication system, and a cooling device. However, CNC machine tools have undergone great changes in the overall layout, appearance, transmission system, tool system structure, and operating mechanism. The purpose of this change is to meet the requirements of CNC machine tools and give full play to the characteristics of CNC machine tools.