Vertical lathe and a double-column vertical lathe, Both single-column vertical lathes and double-column vertical lathes belong to vertical lathes, which are mainly used to process heavy-duty rotating workpieces (such as gears, flanges, and disc parts) with large diameters and short lengths, but there are significant differences in structure, performance, and applicable scenarios.The following analyzes the selection logic from the dimensions of technical parameters, processing capacity, cost, etc.

First.Comparison of core differences

| Compare | Single column vertical lathe | Double-column vertical lathe |

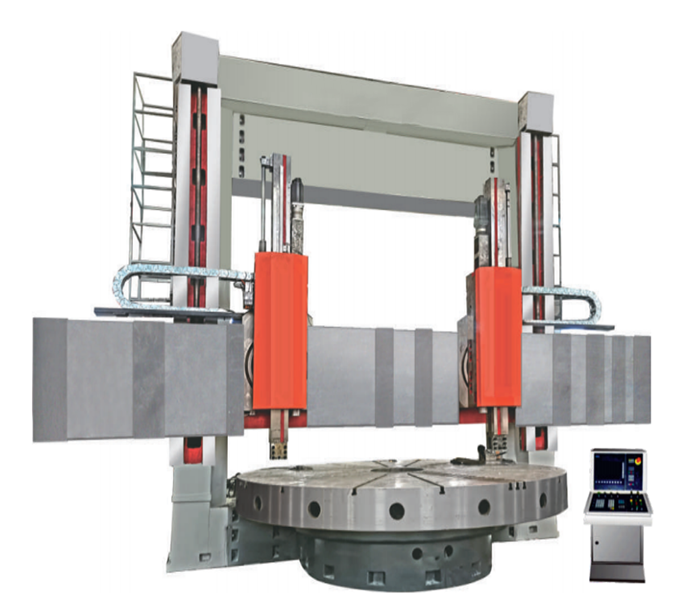

| Product picture |  |

|

| Structural features | It consists of a single column, beam, and workbench, with a compact structure | The frame structure is composed of two left and right columns and top beams, which are more rigid. |

| Machining diameter range | Usually ≤2000mm (small and medium-sized workpieces) | Up to 2000-8000mm (large and ultra-large workpieces) |

| Load-bearing capacity | The workbench has a low load-bearing capacity (generally ≤10 tons) | The workbench has a high load-bearing capacity (up to tens or even hundreds of tons) |

| Accuracy level | Generally used for ordinary precision machining (IT8-IT10) | Can achieve high-precision machining (IT6-IT8), especially suitable for precision large parts |

| Tool range of motion | The beam can only move up and down along the column, and the vertical stroke is limited | The space between the left and right columns is wide, and the tool has a large horizontal movement range. |

| Equipment cost | The structure is simple and the price is low (about 1/3-1/2 of the double column) | The structure is complex and the price is high (large double-column vertical vehicles can reach millions of yuan) |

| Applicable scenarios | Mass production of small and medium-sized disc and ring parts | Single-piece / small-batch processing of large and heavy-duty parts and high-precision workpieces |

Second. Selection basis: 5 key factors

1.Workpiece size and weight

Priority column vertical lathe:

If the diameter of the workpiece is <1500mm and the weight is <5 tons (such as small gears and flanges), the workbench size and load-bearing capacity of the single-column vertical lathe can already meet the needs, and the compact structure saves workshop space.

You must choose a double-column vertical lathe:

When the diameter of the workpiece is >2000mm (such as large bearing outer ring, wind power flange) or the weight is >10 tons, the frame structure of the double-column vertical lathe can provide sufficient rigidity to avoid deformation of the equipment due to excessive workpiece weight during processing.

2.Machining accuracy requirements

Suitable for single-column vertical turning: suitable for ordinary precision machining (such as thread and end face turning), scenarios with tolerance requirements ≤0.05mm (such as agricultural machinery parts, general machinery parts).

Suitable for double-column vertical turning: Due to its strong rigidity and high precision of the guide rail, precision turning (such as mirror turning and thin-walled parts processing) can be achieved. Workpieces with tolerance requirements ≤0.02mm (such as aviation engine casing and nuclear power sealing ring) must be used with double-column vertical turning.

3.Workpiece shape and processing content

Applicable scenarios for large single-column vertical vehicles:

Suitable for turning, drilling, and boring of simple rotary body parts (such as cylinders and cones);

Ensure that there are no complex curved surfaces on the side of the workpiece, and there is no need for a wide range of tool movement (such as the end face machining of ordinary flange).

The advantage scene of the new double-column vertical lathe:

For the forming and turning of large curved parts (such as ship propellers and large heads), the tool needs to move laterally in a wide range between the left and right columns.;

Multi-position, multi-process centralized processing (such as multi-faceted turning of large mold frames to reduce the number of workpiece clamping).

4.Production efficiency and batch volume

Suitable for single-column vertical lathe: suitable for small and medium-sized mass production (such as single pieces or less than 100 pieces), the structure is simple and easy to maintain, and the tool change and debugging efficiency are high.

Imported double-column vertical lathe: Although the equipment cost is high, the efficiency advantage is obvious when processing large workpieces (such as one-time clamping to complete multi-faceted processing), which is suitable for single-piece /small batch production in heavy machinery, energy equipment and other fields.

5.Budget and workshop conditions

Processing cost priority: If the processing needs are mainly small and medium-sized workpieces, the single-column vertical lathe is more cost-effective (for example, a 1.5-meter single-column vertical lathe is about 500,000-800,000 yuan, and a double-column vertical lathe of the same specification is about 1.5-2 million yuan).

Workshop space: The double-column vertical lathe covers a large area (for example, the 3-meter double-column vertical lathe covers an area of about 10×8 meters). It is necessary to ensure the height of the workshop (≥5 meters) and load-bearing (the foundation needs to be reinforced), and the single-column vertical lathe has low site requirements.

Final Recommendation:

Suitable for small and medium-sized workpieces, ordinary precision, and low cost requirements: single-column vertical lathe is preferred, taking into account cost performance and practicality;

Suitable for large and heavy-duty workpieces, high-precision requirements, and multi-process processing: double-column vertical turning must be selected to ensure processing rigidity and accuracy;

Suitable for special scenarios (such as large workpiece diameters or composite machining): You can consult ANTISHICNC for customized solutions (such as the installation of CNC systems or special accessories for double-column vertical vehicles).

When selecting, it is necessary to comprehensively evaluate the workpiece parameters, accuracy requirements, production batch and budget. If necessary, samples of the workpiece can be brought to the manufacturer for trial processing to verify the applicability of the equipment.

Shanghai ANTISHICNC is a professional manufacturer of CNC vertical lathes. We have rich production and processing experience. We can recommend the most suitable vertical lathe for your products and give suitable suggestions for use. We can provide you with professional technical support. We mainly have vertical lathes, horizontal horizontal lathes, CNC milling machines, etc. If you have vertical lathe production needs, please contact Shanghai ANTS company, company email:contact@antsmachine.com

Keywords: CNC vertical lathe, Vertical lathe, Single-column vertical lathe, Double-column vertical lathe