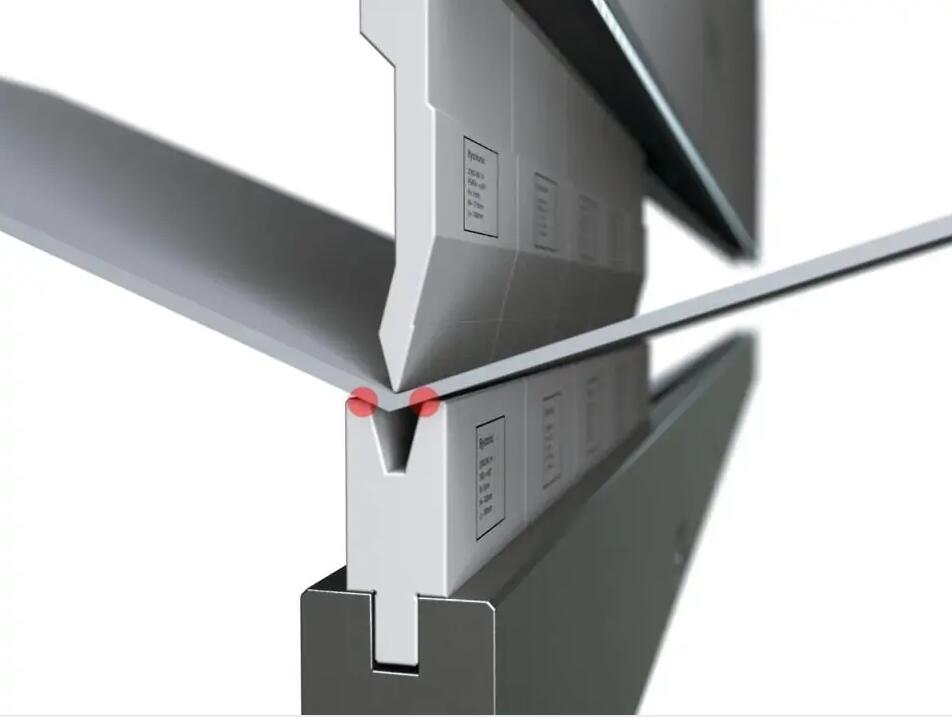

Bending is a process of folding and bending flat panels. It follows the cutting process in the entire processing chain. The workpiece is placed on a die with a V-shaped opening. The wedge cutter (upper knife) presses the workpiece into the V-shaped opening and in this way bends the sheet to the required angle.

The main cutting edge of a Bending Machine is a cylindrical surface, and the cutting edge on the end surface is a secondary cutting edge. A bending machine without a center edge cannot feed along the axial direction of the milling cutter when it is working. According to national standards: the diameter of the bending machine is 2-50 mm, and it can be divided into two types: coarse teeth and fine teeth. Diameter 2-20 is the range of straight shank, diameter 14-50 is the range of taper shank.

The standard bending machine has two kinds of coarse teeth and fine teeth. The number of teeth of the coarse-tooth bending machine is 3~4, and the helix angle β is larger. The number of teeth of the fine-tooth bending machine is 5-8, and the helix angle β is smaller. At the same time, pay attention to three types in the bending machine processing: 1. Clamping, most of the bending machines used in the machining center adopt the spring clamp set clamping method, which is in the cantilever state during use. 2. Vibration, due to the small gap between the bending machine and the tool holder, the tool may vibrate during the machining process. 3. End edge cutting. In the numerical control milling of the cavity of a workpiece such as a mold, when the cut point is a concave part or a deep cavity, the extension of the bending machine needs to be lengthened. Finally, the choice of cutting speed mainly depends on the material of the workpiece to be processed, and the choice of feed speed mainly depends on the material of the workpiece to be processed and the diameter of the bending machine.

Three-point bending

When performing hollow bending, the upper knife presses the workpiece into the opening of the die, but it does not press to the bottom of the die. The workpiece rests only on the two edges of the die during the entire bending process. The bending angle is determined by the depth of the upper knife into the die. Hollow bending can achieve different bending angles without changing the mold.

Bending machines are currently widely used in various departments such as automobile manufacturing, electronics, molds, and machinery. The current major equipment providers include Salvagnini, Bystronic, Amada, Trumpf, etc. international well-known brand.