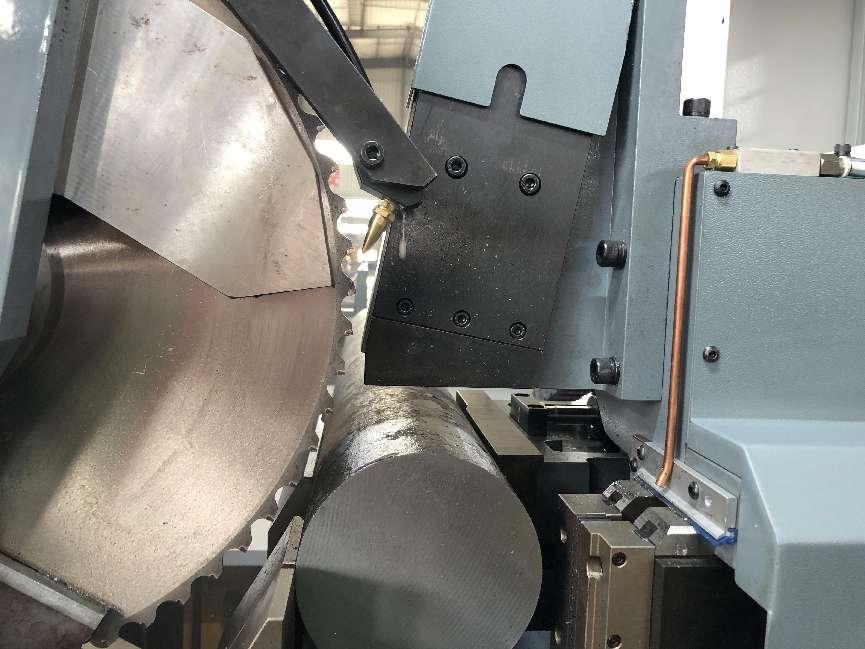

The metal circular saw is a hydraulic type, with vertical slides for advancing and retreating, the feeding structure is firm, the action is precise, and the floating material seat does not hurt the surface of the work piece. Below, we will briefly introduce the operation method of the metal circular sawing machine from Shanghai Antis.

The operation method of metal circular saw machine:

1.Operators are only allowed to operate after passing the examination and obtaining an operation certificate. The operator should be familiar with the performance, structure, etc. of the metal circular saw equipment, and abide by the safety and shift system.

2.Before working, inject (grease) in strict accordance with the lubrication diagram to keep the oil amount appropriate and the oil path unobstructed.

3.Run dry for about 10 minutes, check the transmission parts, lubrication, hydraulic and cooling systems, and check whether the vise is normal. Only when the lubricating oil temperature is greater than 20 °C can it be officially operated.

4.The material to be sawed should be placed stably. Depending on the shape of the cross-section, the material-bearing edge should be used, which should be placed in one piece or directly, and clamped firmly. When multiple pieces are clamped, check whether they are fully clamped.

5.If the sawn material has a large bend, it should not be clamped in multiple pieces.

6.When lifting and unloading (transporting) long materials, pay attention to whether there are people around, and long materials should be mounted on brackets. The operation of more than two people should be directed by one person and coordinate with each other.

7.Select the appropriate cutting speed according to the variety and hardness of the cutting material.

8.The saw blade should be covered with a safety cover, and the human body should not be close to the running saw blade.

9.The operator is not allowed to leave during operation, and the power switch should be turned off when the power is cut off.

10.Check and clean the equipment after work, do a good job in daily maintenance, put each handle (switch) in the neutral position (zero position), and disconnect the power switch to achieve neatness, cleanliness, lubrication and safety.

11.Fill in the relevant records carefully.

If you want to know more about ANTS, please visit our official website.

Our website:http://www.antsmachine.com

If you have any other questions, please contact us directly by email.

Our eail: Contact@antsmachine.com