CNC pipe bending machines are widely used in aerospace, automobile manufacturing, shipbuilding, machinery manufacturing, architectural decoration and other fields. In these fields, CNC pipe bending machines can process various complex shapes of pipe parts to meet the needs of different industries.

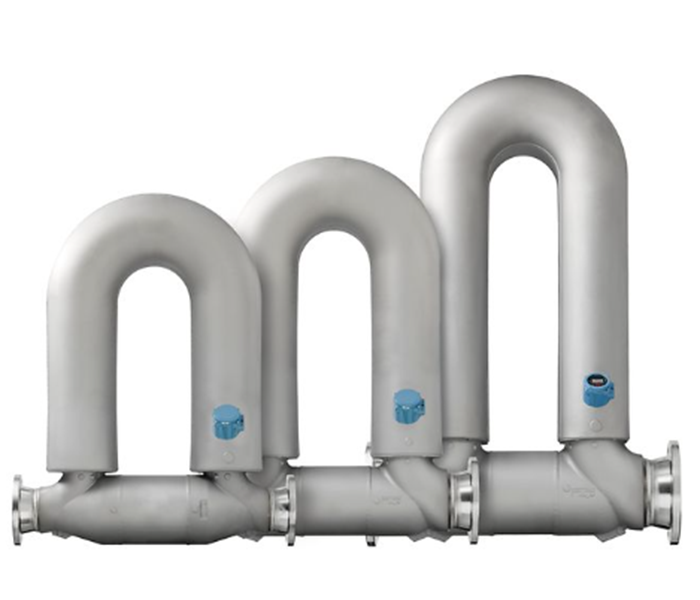

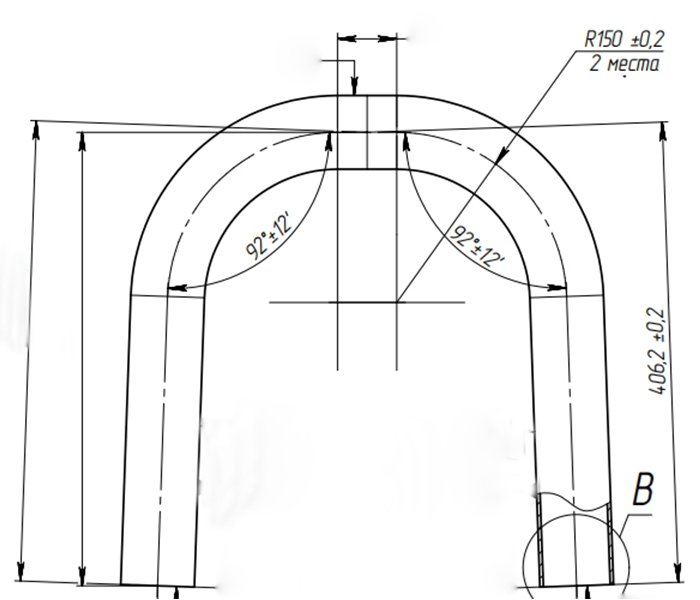

Recently, ANTISHICNC team received an inquiry. The customer requires automatic and precise bending of stainless steel pipes for the production of Coriolis flow-meters. The pipe bending machine is applied to stainless steel AISI SS316L pipes with a maximum size of 110×8 (DN=110 mm, wall thickness = 8 mm)The accuracy requirements are as follows:

Accuracy of bending: 0.05degree

Accuracy of linear tube shifting: 0.05mm

Accuracy of tube rotation: 0.05degree

|

|

Through further communication of needs, we recommended this hybrid heavy-duty pipe bending machine CNC139REM+RBE-8A to the customer.

| Basic technical data | Unit | CNC139REM+RBE-8A | |

| Maximum bending capacity round pipe mild steel>1.5D | mm | Φ139×5.0 | |

| Maximum bending capacity round stainless pipe>1.5D | mm | Φ139×2.0 | |

| Number of die layer | layer | Multi-stacks | |

| Maximum mandrel length | mm | 7800 | |

| Maximum feeding trip | mm | 6000 | |

| Feeding pipe center height | mm | 1250 | |

| Feeding method | mm | Direct or clip | |

| Range of bending radius | mm | 500 | |

| Angle of maximum bending | degree | 190° | |

| The number of pipes can be set per pipe fittings | bends | 30 | |

| Working speed | Y axis Pipe feeding speed | mm/second | Max.500mm |

| B axis Pipe rotating speed | degree/second | Max.90° | |

| C axis Pipe bending speed | degree/second | Max.40° | |

| X axis Machine head left and right displacement moving speed | mm/second | Max.250mm | |

| Z axis Machine head up and down displacement moving speed | mm/second | Max.300mm | |

| Operating accuracy | Bending angle (repeated) | degree | ±0.05° |

| Transfer angle (repeated) | degree | ±0.05° | |

| Delivery length (repeated) | mm | ±0.05mm | |

| Data input method | Coordinate value (XYZ) or working value (YBC) or 3D | ||

| B axis-Tube rotating servo motor power | KW | 2.9 | |

| Y axis-Tube feeding servo motor power with RBE | KW | 15.0 | |

| C axis-Tube bending servo motor power | KW | 30.0 | |

| X axis– Cartridge left & right movement servo motor power | KW | 1.3 | |

| Z axis– Cartridge up & down movement servo motor power | KW | 1.8 | |

| A axis-Mandrel left & right movement servo motor power | KW | 1.3 | |

| AZ1 axis-Mandrel up & down movement servo motor power | KW | 1.8 | |

| T1 axis-Tube support servo motor power | KW | 1.0 | |

| Hydraulic motor power | KW | 22.0 | |

| Machine gross weight | kg | 18000 | |

| Machine size L.W.H | mm | 9800*2780*2300 | |