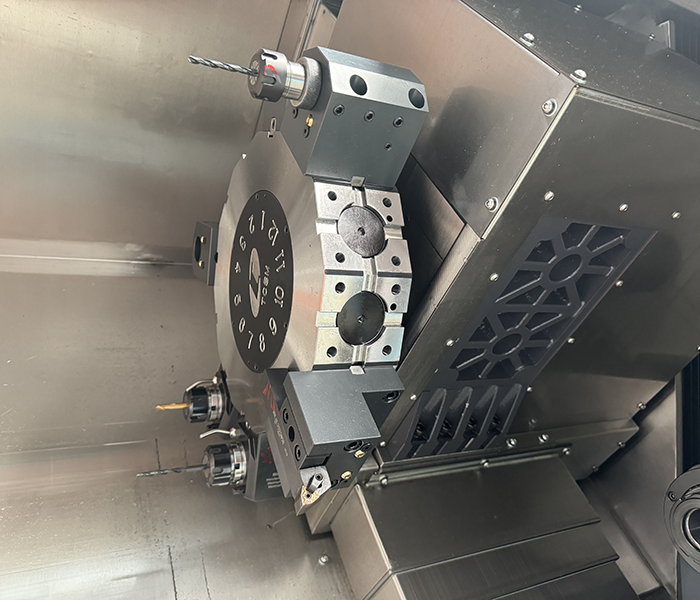

In turning and milling cnc machine tools, the power turret is mainly used to clamp the tool and provide rotating power to realize milling, drilling and other processing actions.It is the installation and power supply device of the tool, not the coordinate axis.

The Y-axis is a linear axis in the machine tool coordinate system, which is used to control the tool or workpiece perpendicular to the lathe spindle.It is usually a linear motion in the direction of the X-Z plane.Therefore, the power turret is not a Y-axis.

The difference between the power turret and the Y-axis:

| Difference | Power turret | Y axis | |

| Different functions | Its function is to install a variety of tools, such as milling cutters, drill bits, taps, etc.There is a drive motor inside the power turret, which can rotate the tool to realize milling, drilling and other processing.For example, when turning and milling a part with a complex shape, the power turret can install a milling cutter to mill the side of the part to create shapes such as planes, grooves, or contours. | The Y-axis is mainly used to control the linear displacement of the tool or workpiece in a specific direction.For example, when machining some parts with eccentric structures or asymmetric shapes, the movement of the Y-axis allows the tool to accurately reach the position to be processed and achieve precise dimensional control. | |

| Different exercise methods | It is mainly rotational movement, and its tool rotates around its own axis.The speed of this rotational movement can be adjusted according to the processing requirements. For example, in milling, the appropriate milling cutter speed can be set according to different materials and machining accuracy requirements. | It is linear motion, through the motor to drive the screw and other transmission devices, so that the tool or workpiece produces accurate linear displacement in the Y direction.The speed of movement and the amount of displacement can be precisely controlled by the CNC system. | |

| Different roles in processing | Focusing on machining through the rotation of the tool, it expands the machining function of the lathe, enabling it to complete a variety of machining processes in a single clamping, such as milling and drilling after turning.This can reduce the transfer of workpieces between different machine tools and improve machining accuracy and efficiency. | It is mainly to assist other coordinate axes (such as X and Z axes) for precise spatial positioning and processing.In some complex three-dimensional curved surface processing or eccentric processing, the participation of the Y-axis can make the processing trajectory more flexible and diverse, and meet the processing needs of complex parts. | |

| Distinguishing method | Observe the structure of the machine tool | The power turret is usually located in the position of the tool holder of the lathe. It is a rotating device with multiple tool mounting positions. The tools and tool holders on the turret can be seen from the appearance. | The driving device of the Y-axis generally includes a motor, a screw, a guide rail, etc. Components such as a guide rail and a slider can be seen along the Y-axis direction, which are used to guide the linear movement of the tool or workpiece in the Y-direction. |

| View CNC system programming instructions | In CNC programming, the control of the power turret mainly involves the selection of the tool, the rotation speed and direction of the tool and other instructions.For example, select the tool on the turret through a specific T code, and use the S code to control the rotation speed of the tool. | The programming instructions of the Y-axis are mainly to control its linear motion. For example, G01 (linear interpolation), G00 (quick positioning) and other instructions are followed by the coordinate values of the Y-axis, which are used to specify the position and speed of the tool’s movement in the Y direction. | |

Shanghai ANTISHICNC is a professional manufacturer of turning and milling CNC machine tools. we have rich experience in production and processing,can recommend the right turning and milling machine for your product, and give the right advice on the use of the turning and milling cnc machine, In addition, we also have We also have CNC lathe, machining centers, etc.Its can provide you with professional technical support. If you need turning and milling cnc machine , welcome to contact Shanghai ANTISHICNC.Please send your inquiry or questions to contact@antsmachine.com for instant feedback.

Tags:Turning and milling machine, Turning and milling composite, CNC lathe.