1.After entering the workshop, you cannot use the machine tools and electrical switches without consent or understanding the performance of the surface grinder.

2.The operator of the surface grinder must master the correct use of the relevant equipment and tools before operating. Ask the engineer immediately if you encounter any problems. It is forbidden to perform trial operations when you are not familiar with it.

3.The surface grinder grinding wheel must be subjected to a static balance test before installation. It is strictly forbidden to use unbalanced grinding wheels. It is necessary to carefully check whether the grinding wheel specifications meet the machine speed requirements. It is strictly forbidden to use grinding wheels with defects and cracks. It should be firm and stable after installation.

4.Before starting the surface grinder grinding wheel, it is necessary to check whether the protective cover is intact and tightened. It is strictly forbidden to use a grinder without protective devices.

5.After the surface grinder grinding wheel is installed, it must be tested for 5 to 10 minutes. Do not start too hastily, and check it by jogging. After starting, idle for 1-2 minutes, and then work after the surface grinder and grinding wheel are running normally.

6.All oil systems of the surface grinder must be unobstructed, and the rotating parts such as the spindle must not be allowed to operate without lubricating oil.

7.When the external cylindrical grinder is clamped with an ejector, the ejector must be pushed into the ejector hole. When the surface grinder processes a high and narrow workpiece or a workpiece with a small bottom contact area, a stopper must be used around the workpiece, and the height of the stopper is 2/3 of the workpiece. The workpiece can only be processed after it is firmly sucked.

8.Strictly abide by the regulations on the grinding wheel of the surface grinder when starting the machine. When the grinding wheel is guided to the workpiece, it should be very even and careful to avoid collision.

9.The position of the stroke positioning block of the surface grinder must be correct and reliable, and it should be checked frequently for looseness.

10.The operator stands on the side of the rotation direction of the surface grinder grinding wheel and must not face the rotation direction of the grinding wheel. It is strictly forbidden to grind the workpiece by hand in front of or on the side of the grinding wheel.

11.When the grinding wheel of the surface grinder moves quickly, the position must be appropriate to prevent the grinding wheel from colliding with the workpiece.

12.Wear a mask when dry grinding workpieces with a surface grinder. When the wet grinding machine is shut down, turn off the coolant first and let the grinding wheel idle for 1-2 minutes for dehydration.

13.When shutting down, the surface grinder grinding wheel must be withdrawn from the workpiece first. Be careful when loading and unloading workpieces or accessories, and do not collide with the grinding wheel or work surface.

14.If the surface grinder is abnormal during operation, the power supply must be cut off immediately and reported to the guiding engineer. Once an accident occurs, measures should be taken immediately to protect the site and report to the relevant department of the company for inspection and repair.

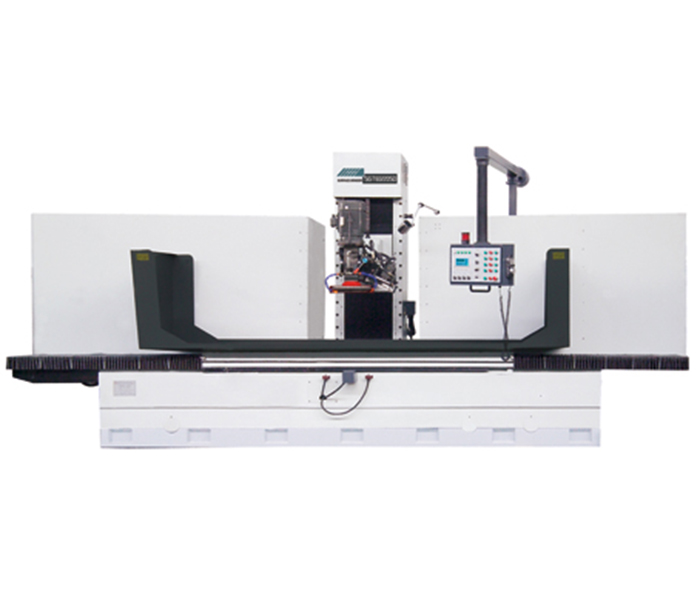

ANTISHI SGT Column Moving Surface Grinder for Rail Grinding

| Technical Description | Unit | SGT60160SD | SGT60220SD | SGT80160SD | SGT80220SD | SGT80300SD | |

| Table size(L*W) | mm | 1600*610 | 2200*610 | 1600*810 | 2200*810 | 3000*810 | |

| Max.grinding size of Work-piece(L*W*H) | mm | 1600*610*600 | 2200*610*600 | 1600*810*600 | 2200*810*600 | 3000*810*600 | |

| Magnetic chuck size | mm | 600*800*2 | 600*1000*2 | 800*800*2 | 800*1000*2 | 800*1000*3 | |

| Table longitudinal speed | mm | 7~23 | 7~23 | 7~23 | 7~23 | 7~23 | |

| Max. loading of table(including magnetic chuck) | kg | 1230 | 1690 | 1630 | 2240 | 3060 | |

| Wheelhead Transverse Moving |

Auto intermittent feed rate | m/t | 1~30 | 1~30 | 1~30 | 1~30 | 1~30 |

| Rapid speed feed | m/min | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 | |

| Hand-wheel feed per gra. | mm/gra. | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | |

| Vertical Wheel Moving |

Wheel head rotation | mm/t | ±30°, ±5° | ±30°, ±5° | ±30°, ±5° | ±30°, ±5° | ±30°, ±5° |

| Rapid speed feed | m/min. | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 | 0.05-2 | |

| Hand-wheel feed per gra. | mm/gra. | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | 0.005/0.05 | |

| Wheel size(OD*Width*ID) | mm | According to process | According to process | According to process | According to process | According to process | |

| Total rated power | KW | 17 | 17 | 17 | 17 | 19 | |

| Gross weight | kg | 8500 | 9500 | 8500 | 9500 | 14000 | |

| Package dimension(L*W*H) | cm | 480*220*172 | 600*220*172 | 480*220*172 | 600*220*172 | 830*220*172 | |

| 260*227*255 | 260*227*255 | 280*227*255 | 280*227*255 | 280*227*255 | |||

If you have any questions, please contact Shanghai ANTS Machine Equipment Co., Ltd. through our website information. Engineers will match you with efficient machine tools and professional services.