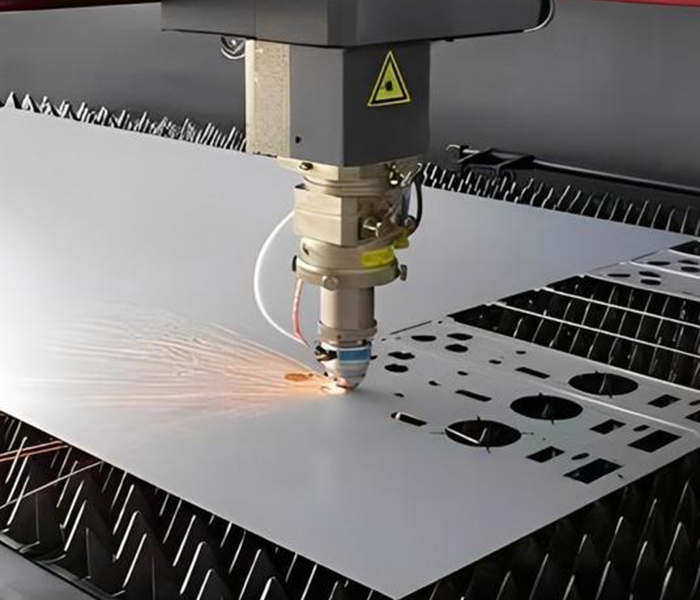

In today’s advanced manufacturing field, laser cutting machine has become an indispensable processing equipment in many industries with its unique advantages. It is widely used in many fields such as metal processing, automobile manufacturing, aerospace, electronics and electrical appliances, and has brought revolutionary changes to modern industrial production.

1. High-precision cutting

Laser cutting machine stands out with its high-precision cutting ability. The extremely small spot formed after the laser beam is focused can achieve millimeter or even micron level cutting accuracy. This means that in the cutting process, whether it is a complex pattern, delicate parts, or workpieces with extremely high size requirements, the laser cutting machine can accurately complete the cutting task. The cutting edge is smooth and flat, without burrs or deformation, which greatly reduces the workload of subsequent processing procedures and improves the quality and consistency of the product. For example, in the electronics and electrical industry, for the cutting of precision circuit boards, laser cutting machines can accurately cut out the shapes of various circuits and components to ensure the performance and reliability of circuit boards.

2. Non-contact processing

Unlike traditional cutting methods, laser cutting is a non-contact processing method. The laser beam does not come into direct contact with the workpiece during the cutting process, avoiding friction and extrusion between the tool and the workpiece, thereby reducing damage and deformation of the workpiece. This is particularly important for the processing of some materials with high hardness and high brittleness, such as ceramics and glass. At the same time, non-contact processing also reduces tool wear and replacement frequency, saving production costs and time. In addition, the laser cutting machine can cut without changing the physical properties of the workpiece material, ensuring the original performance and quality of the workpiece.

3. High cutting speed

The laser cutting machine has an extremely high cutting speed, which can greatly improve production efficiency. The energy of the laser beam is highly concentrated, instantly heating the material to the melting or vaporization temperature, thereby achieving rapid cutting. Compared with traditional cutting methods, such as mechanical cutting and flame cutting, the speed of laser cutting can be increased by several times or even dozens of times. In large-scale production, this advantage is particularly significant, which can greatly shorten the production cycle, reduce production costs, and improve the market competitiveness of enterprises. For example, in the automotive manufacturing industry, laser cutting machines can quickly cut body panels, parts, etc. to meet the needs of efficient production.

4. Strong flexibility

Laser cutting machines are extremely flexible and can adapt to the processing of workpieces of various shapes and sizes. It can accurately control the path and power of the laser beam through a computer control system to achieve cutting of any shape, including straight lines, curves, circles, squares, and various complex patterns. This flexibility gives laser cutting machines a unique advantage in personalized customized production and can meet the diverse needs of customers. Whether it is single-piece production or batch production, laser cutting machines can easily cope with it, quickly switch processing tasks, and improve production flexibility and adaptability.

5. Wide applicability

Laser cutting machines are suitable for cutting a variety of materials, including metal materials such as stainless steel, carbon steel, aluminum alloy, copper, etc., and non-metallic materials such as plastics, wood, leather, paper, acrylic, etc. For the cutting of different materials, you only need to adjust the parameters and processes of the laser to achieve a good cutting effect. This wide applicability has made laser cutting machines widely used in many industries and become a universal processing equipment. For example, in the building decoration industry, laser cutting machines can be used to cut various metal and non-metal decorative materials to produce exquisite decorations and building components; in the medical device industry, laser cutting machines can be used to cut high-precision medical device parts to meet the strict requirements of the medical industry for product quality and precision.

6. Energy saving and environmental protection

Today, with the increasing awareness of environmental protection, the energy-saving and environmental protection advantages of laser cutting machines have also attracted much attention. During the laser cutting process, the energy utilization rate is high, the waste generated during the cutting process is small, and the pollution to the environment is small. Compared with traditional cutting methods, laser cutting does not require the use of a large amount of cutting fluid and gas, which reduces the pollution to the environment and the waste of resources. At the same time, the energy consumption of the laser cutting machine is relatively low, and it can save a lot of energy costs for enterprises during long-term use.

7. Easy automation integration

The laser cutting machine is easy to integrate with the automated production line to realize intelligent production. By combining with automation equipment such as robots and conveyor belts, the whole process of automatic loading, cutting, and unloading of workpieces can be realized, which greatly improves production efficiency and production quality, and reduces labor costs and labor intensity. In modern manufacturing, automated production has become a trend. This advantage of laser cutting machines enables them to better adapt to the development requirements of Industry 4.0 and intelligent manufacturing, and provide strong support for the transformation and upgrading of enterprises.

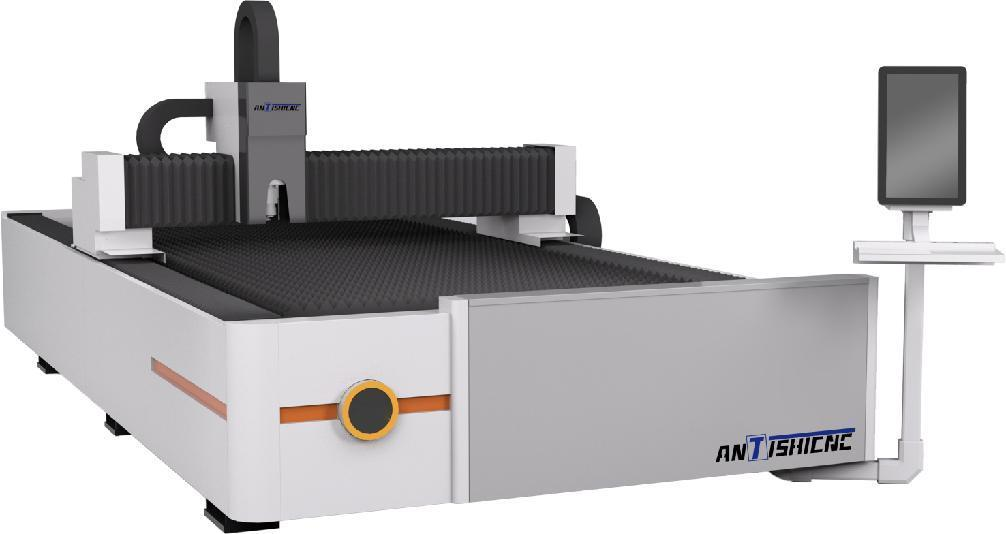

ANTISHICNC is a dedicated and professional laser cutting equipment manufacturer. With advanced technology and exquisite craftsmanship, the company is committed to the research and development and production of high-quality laser cutting equipment. Its products have excellent performance and stable quality, enjoy a good reputation in the industry, and provide many companies with efficient and accurate laser cutting solutions.

AT-3015 is ANTISHICNC hot-selling laser cutting model:

| Model | AT-3015 |

| Working Area | 3000mm×1500mm |

| X/Y/Z Travel | 3000/1500/150mm |

| Laser Wavelength | 1080nm |

| Laser Power | Raycus CE 1500W/2000W/3000W |

| Working Life of Fiber Source | More than 100000 hours |

| Laser Beam quality | <0.373mrad |

| Laser Cutting Head | Raytools Automatic Focus Laser |

| Position Type | Red Dot Pointer |

| Max. Idle Running Speed | 150M/min |

| Geometric Position Accuracy | Within ±0.05mm/M |

| Reorientation Accuracy | Within ±0.03mm/M |

| Lubrication System | Electrical Motored |

| Min. Line Width | ±0.02mm |

| Power Consumption | ≤160KW |

| Transmit system | Dual Rack & Pinion type |

| Auxiliary Gas for Cutting/Assist system | Oxygen, Nitrogen, Air/Germany SMC |

| Compatible Software | AutoCAD, CorelDraw, etc. |

| Handle Control | WIFI Wireless Control Handle |

| Graphic Format | DXF/PLT/AI |

| Power Supply Voltage | 380V/3Ph/50Hz |

| Warranty | 2 Years |

If you have similar processing needs, please feel free to consult ANTISHICNC. We have rich experience in laser cutting manufacturing and application, and can provide you with professional technical support.

Keywords: Laser cutting machine, High-precision cutting,Laser-sheet-cutting