Technical Parameter

| Specifications | Unit | CZ1440G/1 |

| c | mm | 355 |

| Swing over carriage | mm | 220 |

| Swing over gap | mm | 500 |

| Width of bed-way | mm | 186 |

| Distance between centers | mm | 1000 |

| Spindle taper | MT5 | |

| Spindle bore | mm | 38 |

| Step of speed | 8 | |

| Range of speed | rpm | 70-2000 |

| Head nose | D1-4 | |

| Metric thread | mm | 26 kinds(0.4-7) |

| Inch thread | T.P.I | 34 kinds(4-56) |

| Module thread | M.P | 16 kinds(0.35-5) |

| Diametral thread | D.P | 36 kinds(6-104) |

| Longitudinal feeds | mm/r | 0.052-1.392(0.002’’-0.0548’’) |

| Cross feeds | mm/r | 0.014-0.38(0.00055’’-0.015’’) |

| Diameter of lead screw | mm | 22 |

| Pitch of lead screw | 3mm or 8 T.P.I | |

| Saddle travel | mm | 1000 |

| Cross travel | mm | 170 |

| Compound travel | mm | 74 |

| Barrel travel | mm | 95 |

| Barrel diameter | mm | 32 |

| Taper of center | mm | MT3 |

| Motor power | Kw | 1.5(2HP) |

| Coolant motor | Kw | 0.04(0.055HP) |

| Machine(L×W×H) | mm | 1920x760x760 |

| Stand (left)(L×W×H) | mm | 440x410x700 |

| Stand (right)(L×W×H) | mm | 370x410x700 |

| Machine(N.W/G.W) | Kg | 505/565 |

| Stand(N.W/G.W) | Kg | 70/75 |

Equipment Introduction

Can perform internal and external turning, taper turning, end facing, and other rotary parts turning;

Threading Inch, Metric, Module and D.P. ;

Perform drilling, boring and groove broaching;

Machine all kinds of flat stocks and those in irregular shapes;

Respectively with through-hole spindle bore, that can hold bar stocks in larger diameters;

Both Inch and Metric system are used on these series lathes, it’s easy for people from different measuring systems countries;

High anti twist water flat bed, high quality cast iron is carefully manufactured, and the guide surface is treated with intermediatefrequency induction quenching precision;

The guide rail pair composed of polymerizingtetrafluoroethylene guide rail soft belt has good wear resistance, vibration absorption and precision retention;

The spindle adopts three support structure, with good rigidity, high precision and strong cutting;

Wide speed regulation range and reasonable speed can be selected;

lt can directly turn metric and inch threads;

In addition to conventional turning, saddle lathe can also turn all kinds of flat and special-shaped parts;

These series lathes operate on power supply of different voltages (220V,380V,420V) and different frequencies (50HZ,60HZ).

Standard Parts

| 1 | Head wrench |

| 2 | Double-headed wrench |

| 3 | Allen wrench |

| 4 | screw driver |

| 5 | centre |

| 6 | centre hat |

| 7 | change gear |

| 8 | oil gun |

| 9 | tools box |

| 10 | steady rest |

| 11 | follow rest , |

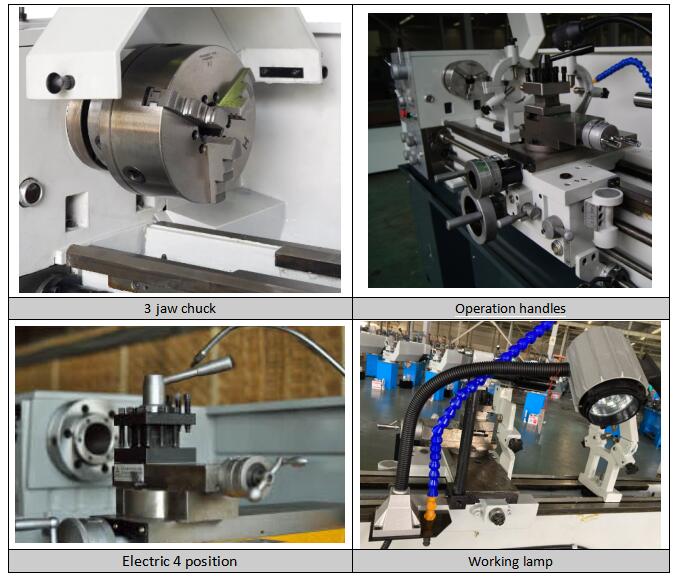

| 12 | 3 jaw chuck |

| 13 | 4 jaw chuck |

| 14 | Stand base |

| 15 | Working lamp |

| 16 | Foot brake |

| 17 | Coolant system |

More Product Details