A grinder (grinding machine) is a machine tool that uses abrasive tools to grind the surface of a workpiece. Most of the grinders use high-speed rotating grinding wheels for grinding processing, a few use other abrasive tools such as oilstone, belts and free abrasives for processing, such as honing machines, super-finishing machine tools, belt grinders, grinders and polishing Machine waiting.

Processing range

The grinder can process materials with higher hardness, such as hardened steel, cemented carbide, etc.; it can also process brittle materials, such as glass and granite. The grinder can perform high-precision and small surface roughness grinding, and can also perform high-efficiency grinding, such as powerful grinding.

Development path

In the 1830s, in order to adapt to the hardened processing of parts such as watches, bicycles, sewing machines and firearms, Britain, Germany and the United States developed grinders using natural abrasive wheels. These grinders were made by adding grinding heads to existing machine tools such as lathes and planers. They were simple in structure, low in rigidity, and prone to vibration during grinding, requiring operators to have high skills in order to produce precision. Artifacts. The Universal Cylindrical Grinding Machine manufactured by Brown-Sharp Company of the United States, exhibited at the Paris Exposition in 1876, was the first machine with the basic characteristics of a modern grinding machine. Its workpiece headstock and tailstock are installed on a reciprocating worktable. The box-shaped bed improves the rigidity of the machine tool and is equipped with internal grinding accessories. In 1883, this company made a surface grinder with the grinding head mounted on the column and the worktable reciprocating. Around 1900, the development of artificial abrasives and the application of hydraulic transmission greatly promoted the development of grinders. With the development of modern industry, especially the automobile industry, various types of grinders have come out one after another. For example, at the beginning of the 20th century, planetary internal grinders, crankshaft grinders, camshaft grinders and piston ring grinders with electromagnetic chucks were developed successively for machining cylinder blocks. The automatic measuring device was applied to the grinder in 1908. Around 1920, centerless grinders, double-face grinders, roll grinders, guideway grinders, honing machines and super-finishing machine tools were successively manufactured and used; in the 1950s, high-precision cylindrical grinding machines for mirror grinding appeared; in the 1960s At the end, high-speed grinders with a grinding wheel speed of 60-80 m/s and large depth of cut, slow-feed grinding surface grinders appeared; in the 1970s, the use of microprocessor-based digital control and adaptive control technologies were widely used on grinders. Applications.

Classification

With the increase in the number of high-precision and high-hardness mechanical parts, as well as the development of precision casting and precision forging processes, the performance, variety and output of grinders are constantly improving and growing.

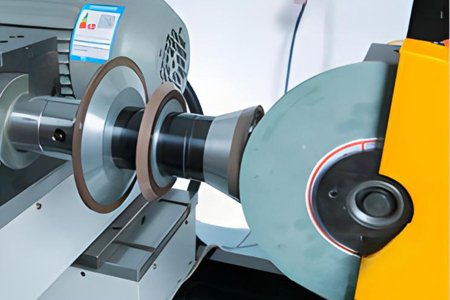

(1) Cylindrical grinder: It is a common basic series, mainly used for grinding cylindrical and conical outer surfaces.

(2) Internal grinder: It is a common basic series, mainly used for grinding cylindrical and conical inner surfaces. In addition, there are grinders with both internal and external cylindrical grinding.

(3) Coordinate grinder: Internal grinder with precise coordinate positioning device.

(4) Centerless grinder: The workpiece is clamped centerlessly, generally supported between the guide wheel and the bracket, and the guide wheel drives the workpiece to rotate. It is mainly used for grinding cylindrical surfaces. For example, bearing shaft support and so on.

(5) Surface grinder: A grinder mainly used for grinding the surface of a workpiece. a. The hand grinder is suitable for processing smaller size and higher precision workpieces, and can process various special-shaped workpieces including curved surfaces, flat surfaces, and grooves. b. The large water mill is suitable for the processing of larger workpieces, and the processing accuracy is not high, which is different from the hand grinder.

(6) Abrasive belt grinder: a grinding machine that uses a fast-moving abrasive belt for grinding.

(7) Honing machine: It is mainly used for processing various cylindrical holes (including smooth holes, axial or radial discontinuous surface holes, through holes, blind holes and multi-step holes), as well as conical holes, elliptical holes, Cycloid hole.

(8) Grinding machine: a grinding machine used to grind the flat or cylindrical inner and outer surfaces of the workpiece.

(9) Guide rail grinder: a grinder mainly used for grinding the guide rail surface of a machine tool.

(10) Tool grinder: a grinder for grinding tools.

(11) Multi-purpose grinder: a grinder that is used to grind cylindrical, conical inner and outer surfaces or planes, and can use follow-up devices and accessories to grind a variety of workpieces.

(12) Special grinder: a special machine tool engaged in grinding certain types of parts. According to its processing objects, it can be divided into: spline shaft grinder, crankshaft grinder, cam grinder, gear grinder, thread grinder, curve grinder, etc.

(13) End face grinder: a grinding machine used to grind the end face of gears

Security

Grinding processing is widely used and is one of the main methods for precision processing of machine parts. However, due to the high speed of the grinding wheel of the grinder, the grinding wheel is relatively hard, brittle, and cannot withstand heavier impact. Occasionally improper operation can cause very serious consequences if the grinding wheel is broken. Therefore, the safety technical work of the grinding process is particularly important, and reliable safety protection devices must be adopted, and the operation must be concentrated to ensure that it is foolproof. In addition, the fine sand and metal shavings splashed from the workpiece of the grinding wheel during grinding can harm the eyes of workers. If workers inhale a large amount of such dust, it is harmful to the body. Appropriate protective measures should also be taken. Attention should be paid to the following safety technical issues during grinding. The machine tool should be thoroughly inspected carefully before driving, including the inspection of the operating mechanism, electrical equipment, magnetic chuck and other fixtures. After inspection, lubricate and test run after lubrication to confirm that everything is in good condition before use. Pay attention to the clamping and clamping when loading the workpiece. The loosening of the workpiece during the grinding process will cause the workpiece to fly out and injure people or break the grinding wheel. When starting to work, use the manual adjustment method to make the grinding wheel slower and approach the workpiece, and the starting feed should be small, and excessive force is not allowed to prevent collision with the grinding wheel. When it is necessary to control the reciprocating movement of the worktable with the stopper, it is necessary to accurately adjust the length of the workpiece according to the grinding length, and the stopper should be tightened. When replacing the grinding wheel, you must first perform a visual inspection to see if there is any trauma, and then hit with a wooden hammer or wooden stick. The sound is required to be crisp and free of cracks. When installing the grinding wheel, it must be assembled according to the specified methods and requirements. After the static balance debugging, the installation and the test run, and everything is normal, then it can be used. Workers should wear protective glasses during work, and dress the grinding wheel in a balanced manner to prevent impact. Measure the workpiece, adjust or wipe the machine tool after stopping. When using a magnetic chuck, clean the disk surface and the workpiece, close it tightly, and suck it firmly. If necessary, add a stopper to prevent the workpiece from shifting or flying out. Pay attention to installing the protective cover of the grinding wheel or the baffle of the machine tool, and stand by the front of the high-speed rotating grinding wheel.

Related information: ANTS machine tools select the best grinder products to our global customers. We offer a one-stop serivce to our customers.