The gantry machining centre is a CNC machine tool widely used in the manufacturing industry. It has become an important tool in modern industry for its high efficiency and precision machining. The gantry machining centre adopts a gantry structure with beams and columns, which enables it to move and position accurately in three axes.

First of all, the gantry machining centre is famous for its high-efficiency machining capabilities. It has a high-speed, high-power spindle, which allows fast and accurate cutting. Compared with traditional machine tools, the gantry machining centre can complete more machining tasks in a shorter time, thereby improving production efficiency. In addition, the gantry machining centre also has an automated tool changing system that can quickly change tools, saving a lot of tool changing time and further improving machining efficiency.

Secondly, the gantry machining centre is favored for its precision machining capabilities. It uses advanced CNC systems and high-precision transmission devices, which make the machining process have high repeatability and machining accuracy. The gantry machining centre can achieve micron-level precision machining, which is suitable for fields with high requirements for workpiece size, shape and surface quality, such as aerospace, automotive molds, etc.

The advantage of the gantry machining centre also lies in its versatility. It can perform a variety of processing operations such as milling, drilling, boring, tapping, etc., and can meet the needs of different industries and application fields. The gantry machining centre is suitable for the processing of various materials, including metals, plastics, composite materials, etc., and has a wide range of applicability.

In addition to the advantages of high efficiency and precision machining, the gantry machining centre also has some other characteristics. For example, it has a large processing range and worktable size, and can handle larger workpieces. At the same time, the gantry machining centre also uses advanced cooling systems and protective devices to ensure the safety and reliability of the machining process.

In short, as a weapon of modern manufacturing, the gantry machining centre is widely used in various fields with its high efficiency and precision machining capabilities. Whether it is aerospace, automobile manufacturing or mold manufacturing, the gantry machining centre can provide high-quality and high-precision machining solutions.

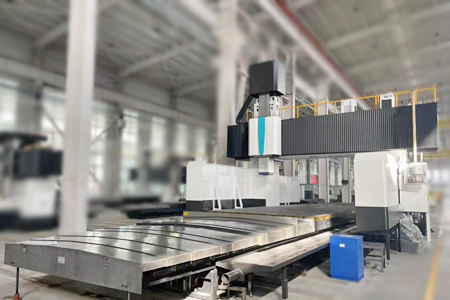

ANTISHI XKW2328FA*40 High speed 3 coordinate machining center CNC Gantry machining centre

| ITEM | Description | Unit | Technical data | |

| Workbench | Dimensions (length X width ) | mm | 2300*4000 | |

| T-slot (size×quantity×spacing) | mm | 11*28*200 | ||

| Weight capacity | Ton | 18 | ||

| Gantry | Distance between two columns | mm | 2800 | |

| Distance from spindle end to worktable | mm | 250-1500 | ||

| Travel | X axis | mm | 4200 | |

| Y axis | mm | 3000 | ||

| Z axis | mm | 1000 | ||

| Fast Speed | X axis | m/min | 10 | |

| Y/Z axis | 10 | |||

| Spindle | Spindle rated power | Kw | 22/26 | |

| Spindle torque | Nm | 770/910 | ||

| Spindle speed | rpm | 10-6000 | ||

| Spindle taper | BT50 | |||

| Ram section size | mm | 400*400 | ||

| Precision | positioning (accuracyGB/T19362.1-200) | X | mm | 0.032 |

| Y | mm | 0.022 | ||

| Z | mm | 0.02 | ||

| Repeatability(GB/T19362.1-2003) | X/Y/Z | mm | 0.022/0.018/0.015 | |

| Others | Total capacity of machine tool power | KVA | 60 | |

| Machine weight (approximately) | T | 45 | ||

| Machine size (length X width X height) | mm | 13000*6500*6700 | ||