1. Customer requirements

Pull 6.5-5.5mm low-carbon busbar to 4.5-2.2mm finished wire

2. Process design ideas and processes

Φ6.5-5.5mm busbar→ Upper-drawing hydraulic lifting double-station unwinding machine

→ DDBK5/8 two-way electric shelling machine

→ GSJ5/8 steel brush polishing machine

→ PMJ5/8 coating machine + HGJ5/8 drying machine

→ LZ7/560 straight-in wire drawing machine (finished wire diameter Φ2.2-4.5mm)

→ SG-1000 Spool winder

3. Production line equipment

1.Upper-drawing hydraulic lifting double-station unwindingmachine

This unwinding machine occupies a small area. The height of the pay-off arm is adjusted by the cylinder telescopic method, which is convenient for threading. In addition, the wire is not easy to be tangled. A tangled wire safety stop switch is installed. Two hydraulic lifting pay-off racks are installed to facilitate wire loading and threading, ensuring that the wire drawing machine does not stop production when drawing wires, saving time and convenience.

2. DDBK5/8 two-way electric shelling machine

| Equipment name and model | DDBK 5/8 Closed type two-way electric sheller |

| Traction wheel motor | 1.5kw×1 unit |

| Wire pressing motor power | 1.5kw ×2 units |

| Shelling wheel material | Made of Cr12 material, quenched, HRC62 |

| Applicable wire diameter | Φ5.0mm – Φ8.0mm |

| Mechanical principle and performance | The machine uses two pairs of traction wheels to automatically pull the wire to the middle of the horizontal and vertical shelling wheels, and then uses a motor to adjust the curvature of the shelling wheels. Six shelling wheels are installed in the shelling box to remove the oxide scale on the surface of the wire in all directions, and the oxide scale is collected in a box in the box so that it can be taken out and cleaned at any time. |

3. GSJ 5/8 steel brush polishing machine

| Equipment name and model | GS J 5/8 Steel Brush Polishing Machine |

| Operation mode | Revolution and rotation |

| Applicable wire range | Φ5.0 mm —Φ8.0 mm |

| Rust removal steel brush speed | 1 000r/min |

| Motor power | 4kw ×4 units |

| Number of steel brushes | 4 pairs (8 pieces) |

| Mechanics | This machine is used to replace pickling equipment. It uses 4 pairs (8 pieces) of steel brushes to revolve and rotate to clean the oxide scale on the surface of the wire, and uses a vacuum cleaner to collect the oxide scale into a box. It is easy to operate and environmentally friendly. |

4. PMJ5/8 CoatingMachine

| Equipment name and model | PMJ5/8 Coating Machine |

| Applicable wire diameter | Φ 5mm- Φ 8mm |

| Motor power | 12kw |

| Heating method | Heating tube, automatic constant temperature |

| effect | This machine is used for boronization (epithelial film), surface coating of wire, which plays a role in protecting and lubricating the surface of wire and preventing corrosion of wire. |

5. HGJ5/8 dryer

| Equipment name and model | HGJ5/8 type drying machine |

| Applicable wire diameter | Φ5.0 mm- Φ8.0 mm |

| Heating fan power | 1 0 kw |

| Heating method | Heating tube, automatic constant temperature |

| effect | The machine dries the boronized wire, and then the wire enters the wire drawing machine for drawing. |

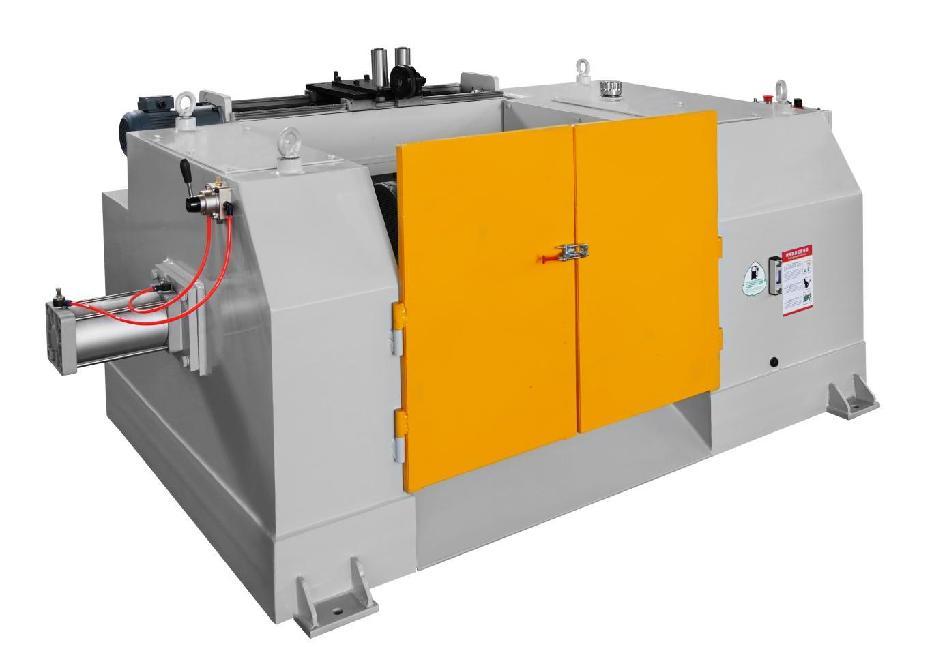

6.LZ7/560 Straight-in wire drawing machine

| Device Model | LZ7/560 straight wire drawing machine |

| Roll diameter | 600mm×1pc, 560mm ×6pcs |

| Drawing pass | 7 |

| Inlet diameter | Φ 6.5-5.5 mm |

| Finished wire diameter | Φ2.2 mm- Φ4.5 mm |

| Incoming line strength | ≤800mpa |

| Maximum compression ratio | 86.56 % |

| Average pass compression ratio | 24.93 % |

| Maximum line speed approx. | 890 m/min |

| Motor power | The 1st to 6th units all use 30kw variable frequency motors, and the 7th unit uses a 37KW variable frequency motor |

| Mold size | Φ40mm × 25 |

| Roll layout | The reel is vertical and tilted |

| Line direction | From left to right |

| Wire pressing device | Each reel is equipped with a wire pressing device to prevent the wire from slipping off the reel when the machine is stopped, thereby reducing the workload of employees and improving work efficiency, making the operation of the entire wire drawing machine more convenient and the automation performance more superior. |

| Pay-off method | After pre-treatment (peeling), it enters the machine for drawing |

| Reeling method | Spool take-up machine |

| Guide wheel, tic-tac-toe roller | The rotating parts in contact with the wire (such as the tic-tac-toe roller , etc.) are sprayed with tungsten carbide, HRC 57-63 |

| Wire drawing die box | ( 1 ) The die box consists of a powder box and a water cooling unit.

( 2 ) The 1st to 7th die boxes all use an automatic rotating stirring die box. The rotating stirring die box can ensure that the lubricating powder is evenly applied to the surface of the wire during the drawing process, thereby improving the lubrication effect, reducing the loss of the wire drawing die and improving the surface quality of the wire. Automatic stirring of the lubricating powder can reduce the workload of the operator and avoid safety hazards when manually stirring the lubricating powder. ( 3 ) The wire drawing die in the die box uses an immersion circulating water cooling method to force the drawing die to cool, ensuring that the drawing die works at normal temperature, thereby improving the service life of the drawing die and ensuring the quality of the wire. |

| Wire drawing reel | Diameter Φ 560mm .

( 1 ) Roll material: cast steel ZG45, surface cladding 4.5mm and sprayed tungsten carbide 0.5mm , HRC 57-63 . Surface roughness less than 0.8umm . ( 2 ) The inside of the roll is treated with zinc-lithium alloy for corrosion protection. |

| Roll cooling | ( 1 ) Internal cooling of the reel: Three water pipes are used to spray water on the inner wall of the reel at 120 degrees. The water is sprayed to all parts of the reel through the blade-type water ring for full-range cooling.

( 2 ) External cooling of the reel: The ventilation pipe under the outside of the reel uses 360 -degree direction to force air cooling on the reel surface and wire to ensure that the wire drawing reel works at normal temperature |

| Tension frame | Built-in tension frame |

| Host rack | Steel plate welding |

| Safety devices | Safety cover, wire breakage detection |

| illumination | Each machine is equipped with individual lighting |

| Parking brake | Pneumatic brake |

| Electric cabinet | Protection grade IP54 |

| Electrical System | Machine distribution structure, PROFIBUS-DP fieldbus control |

| PLC control system and human-machine interface operating system | INOVANCE |

| touchscreen | INOVANCE 10 inch touch screen |

| Frequency conversion motor brand | FANGDA |

| Low voltage electrical appliances | CHNT |

| Frequency Converter | INOVANCE |

| sensor | Shanghai CHUANYUE |

| On-site cable supply | The signal line from the PLC control system to the human-machine interface operating system shall be provided by the seller, and other control cables and power cables shall be provided by the buyer. |

7. Tension machine(Built-in)

- Used to adjust the balance and synchronization of wire drawing and wire taking-up speeds

- Installed on straight-feed wire drawing machines, built-intype

8. SG-1000 Spool winder

| Equipment model | SG-1000 Spool winder |

| I-shaped wheel | Adopt snap-on removable I-shaped wheel |

| Wire diameter | Φ2.0-Φ5.0mm |

| Wire arrangement | Screw rod cable arrangement |

| Brake | Pneumatic brake |

| Thrust pin | Adopt pneumatic automatic ejector |

| Frequency conversion motor power | 22kw |

| Speed regulation mode | Variable frequency speed regulation |

| Frequency converter | INOVANCE |

| Wire weight approx. | 1500kg |

4. Auxiliary equipment

1. ZE-96 Point rolling machine

| Roller diameter (mm) | 96 |

| Maximum rolling diameter (mm) | 8 |

| Minimum rolling diameter (mm) | 2 |

| Equipped motor (kw) | 3kw |

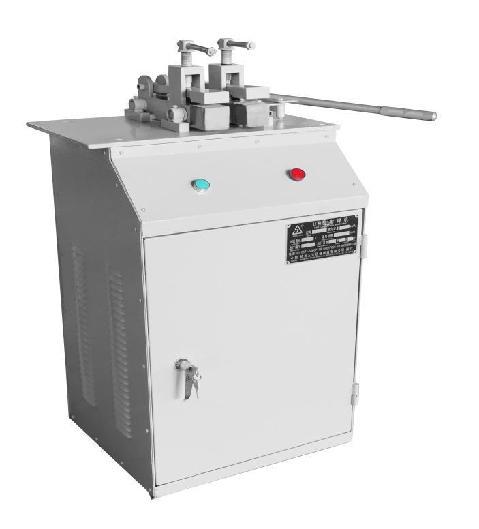

2.UN-10 Butt welding machine

| UN-10 butt welding machine | |

| Applicable maximum diameter (mm) | 8 |

| Applicable minimum diameter (mm) | 2 |

| Rated capacity (KVA) | 10 |