1. What is mirror processing?

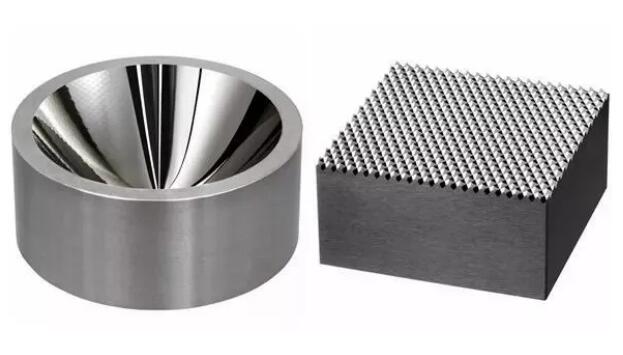

The mirror surface processing system is a system for reshaping a rotating tool. By using a reshaped tool for processing, mirror surface processing can be achieved. Mirror processing can reduce polishing time and avoid the distortion of optical curved surfaces caused by manual polishing in traditional processing technology. It is very suitable for optical mold processing in the 3C and automotive lighting industries.

2. The mirror surface processing system realizes the effect of tool shaping

1) Improve the accuracy of tool radial runout. Due to the runout accuracy of the tool holder and the tool holder and the errors that are considered to be generated when the tool is installed, the tools in traditional machining have a certain runout. The mirror processing system can improve the accuracy of the tool holder and the tool Accuracy causes the problem of tool runout after actual clamping.

2) Improve the shape accuracy of the tool For tools with poor sphericity, especially those worn out after a period of processing, the mirror machining system can improve the sphericity of the tool.

3) Improve tool surface roughness. For tools with poor surface roughness, the shaping function can improve the surface roughness.

3. The composition of the mirror processing system

The mirror surface processing system is composed of a functional program, a tool shaping device, a calibration wheel, a GC reference grinding wheel, a tool shaping device lubricator, a high-precision workpiece automatic measuring device, and a tool shape measuring device.

1) Function program: a numerical control program that realizes the cooperation of the tool, the tool shaping device, the workpiece automatic measuring device and the tool shape measuring device.

2) Tool shaping device: calibration device for grinding and dressing tools.

3) Calibrate the grinding wheel: use for dressing tools.

4) GC reference grinding wheel: dressing and calibrating the grinding wheel.

5) Tool shaping device lubricator: lubricate when dressing the grinding wheel and the tool.

6) High-precision workpiece automatic measuring device: used to detect the diameter and runout of the grinding wheel.

7) Automatic tool shape measuring device: used to measure GC reference grinding wheels and tools.

4. Features of the mirror processing system

The mirror processing system can improve tool runout, sphericity and surface roughness, and improve the surface quality of tool processing. The trimming function of the tool can realize the multiple use of the tool, which greatly reduces the cost of the tool. With Makino iQ series machine tools, high-quality mirror processing can be achieved and polishing time can be reduced.