In order to keep the manual lathe in good condition, in addition to the occurrence of faults in time to repair, adhere to the daily maintenance is very important, on the one hand, can extend the service life of the machine tool, on the other hand, can be eliminated in the bud many hidden faults, to prevent or reduce the occurrence of accidents. Next, the engineer of ANTISHI will tell you what should be done for the daily maintenance of manual lathe?

|

|

|

|

| Contents and requirements

of routine maintenance |

Contents and requirements for periodic maintenance | |

| Maintenance parts | Contents and requirements | |

| First,before processing

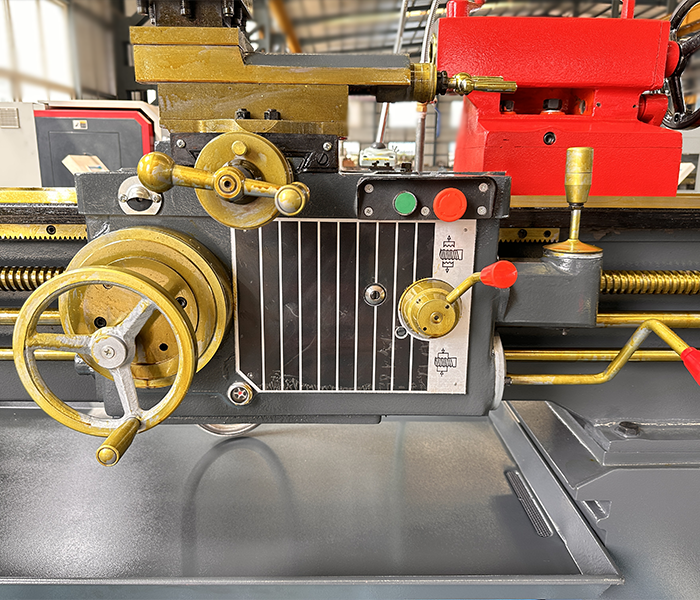

1. Wipe the machine tool exposed rails and sliding surfaces. 2. Lubricate all parts according to the regulations, oil Quality and quantity of oil meet the requirements. 3. Check the position of each handle. 4. Empty lathe test run |

Outer surface | 1. Clean the outer surface of the machine tool and dead ends, dismantle and wash the cover, requiring internal and external cleanliness, no corrosion, no oil, paint to see the colour of the iron to see the light.

2. Clean the screw, light bar, rack and pinion, no grease and dirt. 3. Check and make up the screws, handles and handballs. 1. Disassemble and clean the oil filter. 2. Check the spindle positioning screws and adjust them properly. 3. Adjust the friction disc gap and brake device. 4. Check the oil quality and keep it good. |

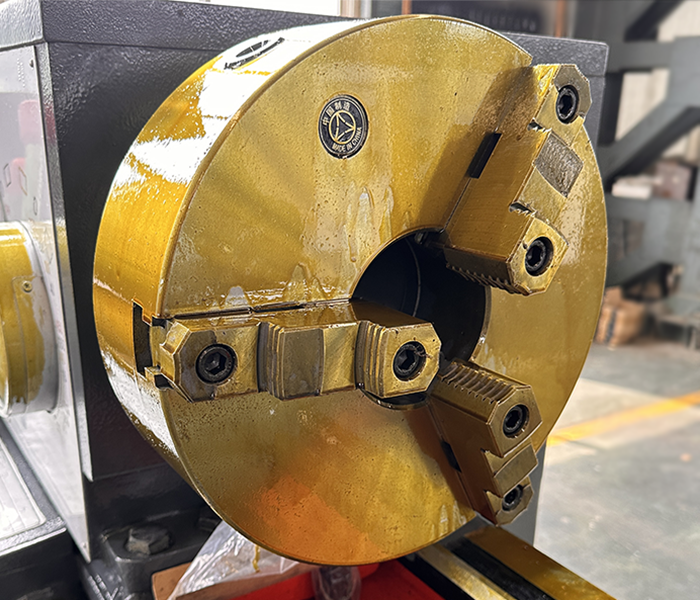

| Headstock | 1. Remove and clean the oil filter.

2. Check the spindle locating screws and adjust appropriately. 3. Adjust the friction disc gap and brake device. 4. Check the oil quality and keep it in good condition. |

|

| Second, after processing

1. Sweep all the chips clean. 2. Wipe all parts of the machine. 3. Return the parts to their places. 4. Carefully fill in the lathe use records, etc. |

Tool holder and slide plate | 1. Dismantle and clean each piece of the knife holder, small skateboard and medium skateboard.

Knife holder and slide plate 2. Adjust the screw clearance and inclined iron clearance of the middle and small slide plates during installation. Iron clearance |

| Exchange gear box | 1. Disassemble and clean the gears and gear frame, and check the bushing for shaking.

Exchange the gear box 2. Adjust the gear lash and fill with new oil during installation. |

|

| Tailstock | 1. Disassemble and clean the tailstock parts.

2. Remove burrs and check the clearance of the screw nut. 3. Require flexible and reliable installation. |

|

| Feed box and slide box | Cleaning of oil lines and felts, filling with new oil | |

| Lubrication and cooling system | 1. Clean cooling pump and cooling tank. Lubrication and cooling system

2. Check the oil quality, maintain good, oil cup is complete, oil window is bright. 3. Clean the oil line and felt, inject new oil, and require the oil circuit to be smooth

|

|

| Electrical system | 1. Clean the dust inside and outside the motor and electrical box.

2. Check and wipe the electrical components and contacts, the requirements are good, reliable, no Dust, safe and reliable line |

|

In addition, the machine tool needs to be maintained after 600h, mainly by the operator and maintenance workers. First cut off the power supply, and then carry out maintenance work.

| Maintenance parts | Maintenance content and requirements |

| External maintenance | 1. Clean the outer surface of the machine tool and each cover, keep the inside and outside clean, no corrosion, no oil.

2. Clean the rail surface, check and trimming burrs. 3. Clean the long screw, light bar, operating rod, clean and free of oil. 4. Make up the fastening screws, nuts, handballs, handles and other parts to keep the machine neat. 5. Clean the machine accessories, clean, neat, rust-proof. |

| Headstock | 1. Clean the oil filter.

2. Check whether the spindle nut is loose, and adjust the positioning screws appropriately. 3. Check and adjust the friction disc gap and brake. 4. Check the transmission gear for misalignment and looseness. |

| Feed box exchange gear box | 1. Clean all parts.

2. Check and adjust the gear clearance. 3. Check the bushings. They should be free from looseness and scratching. |

| Small slide plate | 1. Disassemble and clean the knife frame, adjust the gap between the middle and small slide plate.

2.Disassemble, clean and adjust the clearance of the screw nut of the middle and small sliding plate. |

| Tailstock | 1. Remove and wash the screw and sleeve.

2. Check the burrs on the outer surface and taper holes of the polishing sleeve. 3. Clean and adjust the locking mechanism, remove and wash the lead screw and sleeve |

| Lubrication system | 1. Ensure that the oil hole and oil circuit are smooth. |

| Cooling system | 2. Oil quality, oil quantity meets the requirements, the oil cup is complete, the oil label is bright. |

| Electrical installation | 1. Clean the motor and electrical box.

2. Check the contacts of each electrical component, which should be good, safe and reliable. 3. Check and tighten the zero device. |

In short, doing a good job of daily maintenance of manual lathe is the key to ensure the normal operation of the lathe and extend the service life of the lathe. Only every operator is strictly in accordance with the maintenance procedures, in order to let the manual lathe in the workshop to continue to play its important role in the production of enterprises to provide a solid guarantee.