China’s First Special Shape Grinding Machine

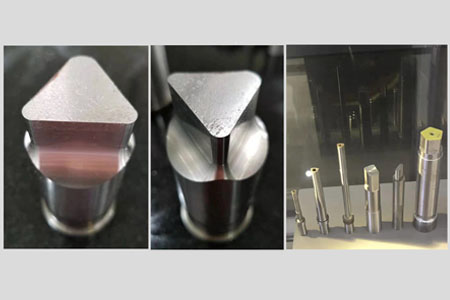

The first high-precision CNC special shape grinding machine in China, which can grind eccentric shaft, polygon, ellipse, cam, etc.

High precision grinding of various non-circular shapes. Replacing the punch industry, the surface grinder+punch former manually grinds shaped workpieces, reducing labor costs while achieving higher precision workpieces.

Can meet the grinding needs of various shapes

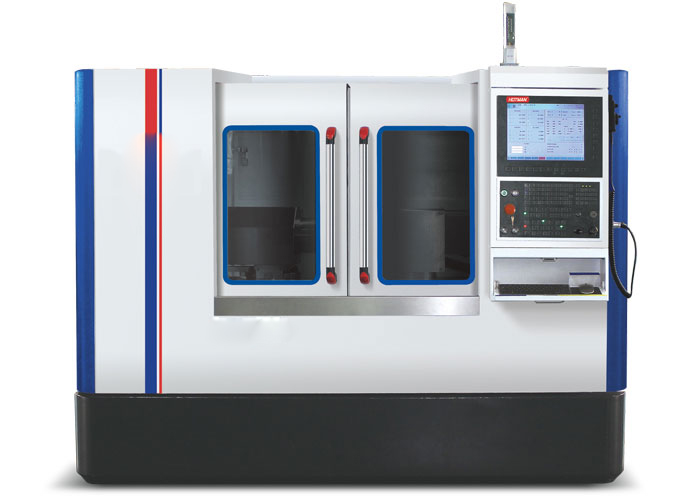

Main Body

The body and components are made of Meehanite cast iron FC-30. After artificial normalization heat treatment and the natural aging treatment, the internal stress of the main body is eliminated, and the precision of the processing surface is maintained.

Automatic Lubrication System

The slides and screws are continuously lubricated by the automatic lubrication system to ensure a longer service life and to maintain optimum accuracy over the long term. The cooling and lubrication system are separate from the main body, eliminating vibration and facilitating heat dissipation.

Grinding Wheel Head

Grinding feed is driven by the latest linear motor for smooth motion, excellent accuracy and repeatability, and long service life.

Wheel Spindle

The grinding wheel electric spindle system adopts oil cooling method and adjusts the line speed according to the requirements of the workpiece to obtain better precision and roughness.

Work Head

It adopts the German Rust DDR rotating motor, which has the characteristics of large torque and high rotation precision.

Control System

The machine tool control system adopts the shape control system from LYNUC, it cooperates with the LYNUC linear motor to obtain high compatibility. The program runs stable and the feed is accurate.

Main Body

The body and components are made of Meehanite cast iron FC-30. After artificial normalization heat treatment and the natural aging treatment, the internal stress of the main body is eliminated, and the precision of the processing surface is maintained.

Automatic Lubrication System

The slides and screws are continuously lubricated by the automatic lubrication system to ensure a longer service life and to maintain optimum accuracy over the long term. The cooling and lubrication system are separate from the main body, eliminating vibration and facilitating heat dissipation.

Grinding Wheel Head

Grinding feed is driven by the latest linear motor for smooth motion, excellent accuracy and repeatability, and long service life.

Wheel Spindle

The grinding wheel electric spindle system adopts oil cooling method and adjusts the line speed according to the requirements of the workpiece to obtain better precision and roughness.

Work Head

It adopts the German Rust DDR rotating motor, which has the characteristics of large torque and high rotation precision.

Control System

The machine tool control system adopts the shape control system from LYNUC, it cooperates with the LYNUC linear motor to obtain high compatibility. The program runs stable and the feed is accurate.