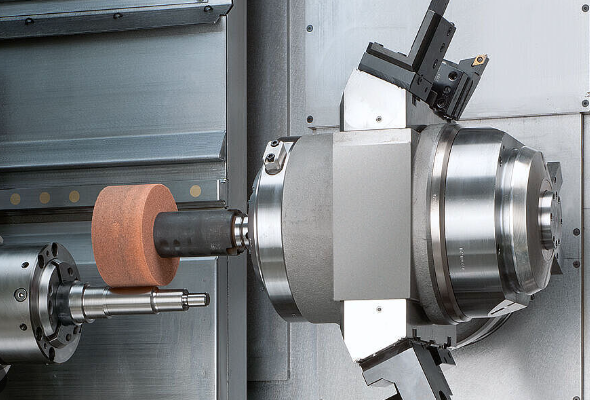

The vertical CNC grinding center is a high-precision, high-efficiency automated grinding equipment that integrates CNC grinding technology, grinding process, grinding design and other disciplines. It is mainly used for precision grinding of various parts to achieve high-precision size, shape and surface quality requirements.

1.Characteristics of vertical CNC grinding center

High precision: The use of high-precision control systems, precision mechanical transmission components and advanced grinding technology can achieve micron-level or even higher precision grinding processing, ensuring the dimensional accuracy and shape accuracy of the workpiece.

Multi-function: It can perform various grinding processes such as external cylindrical grinding, internal cylindrical grinding, surface grinding, and conical grinding, and can also complete the processing of complex contours and special surfaces.

High rigidity: The machine tool structure is reasonably designed, usually using high-quality materials and reinforced structures, with high rigidity, can maintain stability during processing, reduce vibration and deformation, and ensure processing accuracy.

High efficiency: Equipped with an automated loading and unloading system, a fast tool change system and efficient grinding parameters, it can achieve automated continuous processing, greatly improve production efficiency and shorten the processing cycle.

High degree of automation: Programming and control through the CNC system, the operator only needs to enter the processing program and parameters, and the machine tool can automatically complete the grinding process, reducing the error of manual operation and improving the stability of processing quality.

Small footprint: Compared with traditional horizontal machine tools, the vertical structure design occupies a smaller area, which is conducive to the layout and space utilization of the workshop.

|

|

|

2.Application areas of vertical CNC grinding centers

Mold manufacturing industry: used to process key components such as mold cavity, core, fastener, etc., to ensure the precision and surface quality of the mold, and to improve the service life of the mold, such as the processing of automobile molds, injection molds, die-casting molds, etc.

Automobile manufacturing industry: can perform precision grinding on automobile engine cylinder blocks, cylinder heads, crankshafts, camshafts, parts and other parts to ensure the precision and performance of automobile parts, and meet the high reliability and productivity requirements of key parts such as automobile engines.

Aerospace industry: can process key parts such as aircraft engine blades, impellers, integral blades, landing gears, etc. These parts usually have extremely high requirements for precision and surface quality. The vertical CNC grinding center can fully meet the strict processing requirements of parts in the aerospace field.

Machinery manufacturing industry: suitable for processing various mechanical parts such as shafts, gears, screws, bolts, etc., to improve the quality and reliability of mechanical products, and ensure the normal operation and performance of mechanical equipment.

Electronics industry: It can process precision parts in electronic equipment, such as connectors, dormants, silicon wafer grinding in semiconductor chip manufacturing, etc., to meet the processing requirements of the electronics industry for precision and small-size parts.

Medical device industry: In medical device manufacturing, it is used to process artificial joints, medical devices, precision parts in medical equipment, etc., to ensure the accuracy and safety of medical devices, and meet the strict requirements of the medical industry for product quality.

3.Case Analysis—How to Process Automobile Camshafts with Vertical CNC Grinding Machines

Recently, Shanghai ANTS Machine Equipment Co., Ltd. received a Belarusian dealer customer. His end customer is an automobile parts manufacturer that needs a vertical CNC grinder to grind automobile camshafts.

Next, the Shanghai ANTISHICNC engineer will briefly introduce the processing process.

Rough grinding:

Positioning and alignment: After the camshaft blank is clamped on the fixture, the camshaft is positioned and aligned through the machine tool’s measuring system or manual operation, so that the axis of the camshaft and the axis of the grinding wheel of the grinder are in the correct relative position.

Rough grinding of the journal: Start the grinder, and the grinding wheel will roughly grind the journal of the camshaft at a higher linear speed and a larger grinding depth, removing most of the excess, leaving a processing allowance of 0.2-0.5mm for subsequent fine grinding.

Rough grinding of the cam profile: According to the programmed cam profile trajectory, the grinding wheel begins to roughly grind the cam part to initially form the general shape of the cam.

Fine grinding

Grinding wheel dressing: Before fine grinding, the grinding wheel needs to be dressed to ensure the sharpness and surface flatness of the grinding wheel, and to ensure the precision and surface quality of fine grinding.

Fine grinding of the journal: Reduce the feed speed and grinding depth of the grinding wheel, and fine grind the journal to make the dimensional accuracy and surface roughness of the journal meet the design requirements. The cylindrical error of the journal can be controlled within 0.01mm, and the surface roughness reaches Ra0.8-Ra1.6μm.

Fine grinding of cam profile: Fine grinding the cam profile with precise feed speed and grinding parameters, so that the parameters such as the cam lift and profile curve meet high precision requirements.

Detection and compensation

Online detection: During the processing, the size and shape accuracy of the camshaft are measured in real time using the online detection device equipped with the machine tool, such as a laser measuring instrument, a contact measuring probe, etc.

Error compensation: Based on the detection results, the CNC system automatically calculates the error value and adjusts and compensates the motion parameters of the machine tool, such as adjusting the feed rate of the grinding wheel, the position of the worktable, etc., to eliminate the processing error.

For more technical details and knowledge of grinding machines, please contact Shanghai ANTS Machine Equipment Co., Ltd. We provide customers with timely technical support, training and high-quality machine tools.

Keywords: Grinder, Vertical CNC grinder, Application of vertical CNC grinder