In the field of modern mechanical processing, vertical machining centers occupy an important position. Today, the engineers of Shanghai ANTISHICNC will lead you into the world of vertical machining centers and appreciate its unique charm and powerful functions.

1.Definition and characteristics of vertical machining center

Vertical machining center is a highly automated CNC machine tool with a tool magazine and automatic tool changer. Its spindle is perpendicular to the worktable and is mainly used for processing complex parts such as plates, discs, molds and small shells.

Its main features include:

a. High precision: The use of advanced CNC system and precise mechanical structure can achieve high-precision processing and ensure the dimensional accuracy and surface quality of parts.

b. High efficiency:The automatic tool changer and high-speed spindle make the processing process faster and greatly improve production efficiency.

c. Versatility:It can perform milling, drilling, boring, tapping and other processing operations to meet the processing needs of different parts.

d. Good stability:The structure is strong and can withstand large cutting forces to ensure the stability of the processing process.

2.Components of vertical machining center

a. Machine tool body: including bed, column, workbench, etc., providing stable support and working platform for machining center.

b. Spindle system: composed of spindle motor, spindle box, spindle, etc., responsible for providing cutting power.

c. Feed system:including guide rails, lead screws, servo motors, etc., to achieve precise movement of workbench and spindle.

d. Tool magazine and automatic tool changer: used to store tools and automatically change tools during machining.

e. CNC system: It is the core part of machining center, controlling various actions and machining processes of machine tools. Common systems include GSK system, Siemens system and FANUC system.

|

|

|

3.Working principle of vertical machining center

First, according to the machining requirements of the parts, the machining program is compiled and input into the CNC system. According to the program instructions, the CNC system controls the spindle and feed system to move precisely, and controls the tool magazine and automatic tool changer to select the appropriate tool. During the machining process, the tool cuts the workpiece, removes excess material, and gradually forms the required part shape. After the machining is completed, the machine tool automatically stops running and waits for the next machining task.

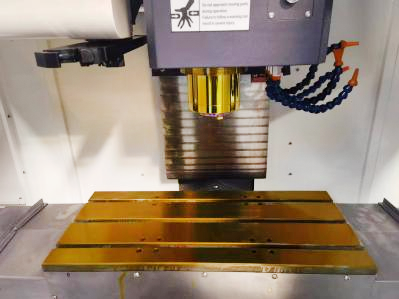

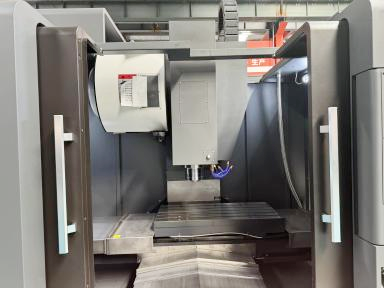

Next, the Shanghai ANTISHICNC engineer will take you to appreciate the physical pictures of the products processed by our VMC.

|

|

|

4.Application fields of vertical machining centers

a.Automobile manufacturing: used to process engine cylinder blocks, cylinder heads, transmission housings and other parts.

b.Aerospace: processing aircraft structural parts, engine parts and other high-precision parts.

c.Mold manufacturing:manufacturing various plastic molds, stamping molds, etc.

d.Electronic equipment manufacturing:processing precision parts such as mobile phone cases and computer cases.

5.Choose a vertical machining center from the perspective of processing requirements

a.Part size and weight

Determine the worktable size and maximum load capacity of the vertical machining center to meet the size and weight requirements of the parts to be processed. If you are processing large parts, you need to choose a machining center with a large worktable and strong load capacity.

For example, processing large parts such as automobile engine cylinders requires a large worktable and high-load-carrying equipment to ensure that the parts are stably placed during processing.

b.Processing accuracy requirements

For parts processing with high precision requirements, a vertical machining center with high positioning accuracy and repeatability should be selected. This usually depends on the structural design of the machine tool, the transmission system, and the performance of the CNC system.

For example: the processing of electronic components requires extremely high precision, so it is necessary to select a machining center with micron-level precision.

c.Processing complexity

If the part shape is complex and requires multi-axis linkage processing, then a machining center with corresponding functions must be selected. For example: processing complex curved surface parts in the aerospace field may require a five-axis linkage vertical machining center.

For general simple part processing, a three-axis machining center may be sufficient to meet the needs.

6.Case Analysis – VMC650

Recently, Shanghai ANTISHICNC Machine Equipment Co., Ltd. received an inquiry from the client. According to the customer’s processing requirements, we recommended our VMC650 vertical machining center to the customer. The worktable size is: 900*450mm. The spindle taper is BT40. The standard tool magazine has 16 tools.

Next, the Shanghai ANTISHICNC engineer will introduce how to choose a suitable vertical machining center. The main concerns are the X/Y/Z axis travel, the size and load of the worktable, and the type of CNC system required. According to these factors, you can basically select a simple model.

Please see the following simple basic technical parameter table of VMC650:

| Specifications | VMC650 Machine Center |

| Travel | |

| X-Axis Travel | 800mm |

| Y-Axis Travel | 450mm |

| Z-Axis Travel | 500mm |

| Distance from spindle end face to worktable | 120-620mm |

| Distance from spindle center to column guide surface | 520mm |

| Worktable | |

| Working desk size | 900×450mm |

| Maximum load-bearing capacity of workbench | 500kg |

| T-slot size | 3×18×95mm |

| Feed parameters | |

| X-axis rapid movement speed | 36m/min |

| Y-axis rapid movement speed | 36m/min |

| Z-axis rapid movement speed | 36m/min |

| Feed movement speed X, Y, Z | 1-12m/min |

The VMC650 vertical machining center is mainly used for machining high-precision, multi-process, and complex-shaped parts such as plates, discs, shells, and molds. It can continuously complete milling, drilling, expansion, reaming, boring, tapping, and two-dimensional and three-dimensional curved surfaces and precise processing of inclined surfaces in one clamping. The processing is programmed, shortening the production cycle, so that users can obtain good economic benefits.

For more technical details and knowledge of vertical machining centers, please contact Shanghai ANTS Machiner Equipment Co., Ltd. We provide customers with timely technical support, training, and high-quality machine tools.

If you want to learn more about Shanghai ANTISHICNC’s VMC, please check our official website: vmc650-series-machining-center

Keywords: CNC machine tools, vertical machining centers, high-precision machining