The universal milling machine is a general-purpose metal cutting machine that can perform vertical and horizontal cutting. It has multiple processing functions and high flexibility, and can perform milling processing on workpieces of various shapes.

Working principle: The working principle of the universal milling machine is based on the basic principle of metal cutting. The spindle drives the milling cutter to rotate at high speed, and the worktable drives the workpiece to move in a straight line or curve, so that the milling cutter and the workpiece produce relative cutting motion, thereby realizing the processing of the workpiece. Among them, the rotation of the milling cutter is the main motion, which provides the main power and cutting speed for cutting; the movement of the workpiece driven by the worktable is the feed motion. By controlling the speed and direction of the feed motion, the position and size of the cutting can be accurately controlled. In addition, according to the specific needs of the processing, the relevant parameters of the machine tool, such as spindle speed, feed speed, cutting depth, etc., can be adjusted to meet different processing requirements, complete the processing tasks of various surfaces such as planes, grooves, gears, cams, curved surfaces, etc., and can also perform processing operations such as drilling and reaming.

Application fields:

Mechanical manufacturing field

Plane milling: It can perform plane milling on the surfaces of various mechanical parts, such as the upper and lower surfaces, sides, etc. of parts such as boxes, bases, and plates, which can ensure the flatness and finish of the plane and provide a basis for subsequent assembly and processing; Groove machining: It can process grooves of various shapes, such as keyways, dovetail grooves, T-slots, etc. These grooves are often used in mechanical parts to install keys, sliders and other components to achieve connection and positioning between parts; Gear machining: By using special gear milling cutters, universal milling machines can process various types of gears, such as cylindrical gears, bevel gears, etc.

Mold manufacturing field

Processing cavity and core: The cavity and core of the mold usually have complex shapes. The universal milling machine can control the movement of the workbench and the tool through programming, and perform milling on the mold blank to gradually form the required cavity and core shape; Processing mold structural parts: Some structural parts in the mold, such as templates, pads, guide columns, etc., can also be processed on the universal milling machine. Various mounting holes, grooves and other structures can be processed to ensure the dimensional accuracy and assembly accuracy of these parts, and ensure the overall performance and service life of the mold.

Automobile manufacturing field

Processing engine parts: There are many planes, grooves and holes on engine cylinder blocks, cylinder heads and other parts that need to be processed. Universal milling machines can be used to mill the planes, oil channel grooves of the cylinder block, and valve seat grooves on the cylinder head, etc., to ensure the normal operation of the engine; Processing automobile chassis parts: Some brackets, beams and other parts in the chassis need to be milled to obtain the appropriate shape and size.

Aerospace field

Processing aircraft structural parts: The wing beams, fuselage frames and other structural parts of the aircraft are usually made of high-strength aluminum alloys or titanium alloys. Universal milling machines can mill these materials, and by precisely controlling the processing parameters, the dimensional accuracy and surface quality of the structural parts can be guaranteed, while reducing the weight of the structural parts and improving the performance of the aircraft; Processing aircraft engine parts: The blades, impellers and other parts of the aircraft engine have complex shapes and require extremely high processing accuracy. The universal milling machine combines advanced CNC technology and tools to perform rough processing and semi-finishing on these parts, providing a basis for subsequent precision processing and ensuring the efficient operation of the engine.

Recently, Shanghai ANTISHI received an inquiry from a Hong Kong customer who needed a universal milling machine with a table size of 1600mm and x/y/z travel of 1300/300/450. Through the customer’s email and other information, we recommended our universal milling machine X6036CL to the customer.

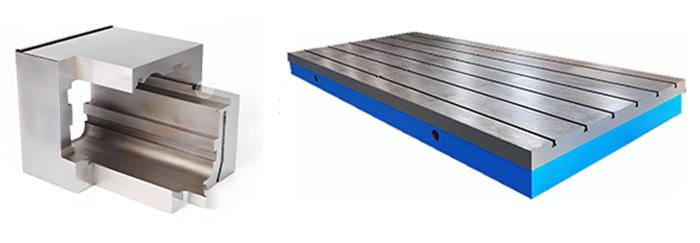

Photo display of machinable workpieces:

Shanghai ANTISHI Universal Milling Machine X6036CL

The main parameters of the machine are as follows:

| Specifications | X6036CL |

| Worktable size (L×W) | 1600x360mm |

| T slot (Width x No. x pitch) | 18x3x80mm |

| Distance between spindle nose and table | 20-420 |

| Distance from spindle axis to arm | 175 |

| Worktable longitudinal travel (X) | 1300mm |

| Worktable longitudinal travel (Y) | 300mm |

| Worktable longitudinal travel (Z) | 450mm |

| Arm travel | 500mm |

The universal milling machine has the characteristics of diverse processing functions, relatively high processing precision, strong operation flexibility, wide adaptability to cutting tools, high production efficiency, and low processing cost. We not only have universal milling machines, gantry machining centers, boring and milling machines, turret milling machines, turning and milling compound centers, but also lathes, sawing machines, grinding machines, drilling machines, planers, and slotting machines. If you have similar needs, you are welcome to consult Shanghai ANTS Machine at contact@antsmachine.com. Our technical team will definitely be able to match the most suitable technical solution for you.

Keywords: milling machine, turret milling machine, high precision, vertical manual milling machine