Perlite board is a lightweight board made of perlite as the main raw material, after crushing, screening, mixing, pressing and other processes. perlite board has low density, low thermal conductivity, fireproof, sound insulation, corrosion resistance, non-toxic, environmentally friendly and other excellent properties, is a new type of environmentally friendly building materials, widely used in building insulation, sound insulation and other fields. Perlite board production equipment is generally used in hydraulic press machines, using molding process, using the hydraulic system as a power source, through the high pressure on the perlite particles and adhesive mixture pressed into shape, so as to produce perlite insulation board.

So, what are the characteristics of perlite board molding hydraulic press machine?

1. Adopting PLC human-machine interface control system, automatic feeding, automatic pressing, automatic ejecting, automatic launching of products, producing 2 plates each time within 15-20 seconds, which is more than 2 times of the production capacity of traditional equipment.

2. Realize double-sided pressurized molding through the floating of mold frame, so that the density of molded cake pieces is uniform, and improve the appearance quality of demolded products. Hydraulic system adopts combined stacked valve block to realize continuous full-load work without failures, molding limit switch is adjusted according to technical parameters to realize stable and adjustable size of molded products; assembled with water-cooling device to avoid high oil temperature, to protect the machine from continuous normal operation.

3.It has independent power system and electric system, adopting PLC and touch screen control mode, with pointing and semi-automatic function. Semi-automatic, press both hands to start the button to achieve the automatic molding of powder loading, pressing, floating pressing, demolding; point of time every time you press the button that is to achieve the current action, release the button that is to stop the action.

4.The working pressure and working stroke of the machine can be adjusted within a certain range, which can meet the process needs of different products.

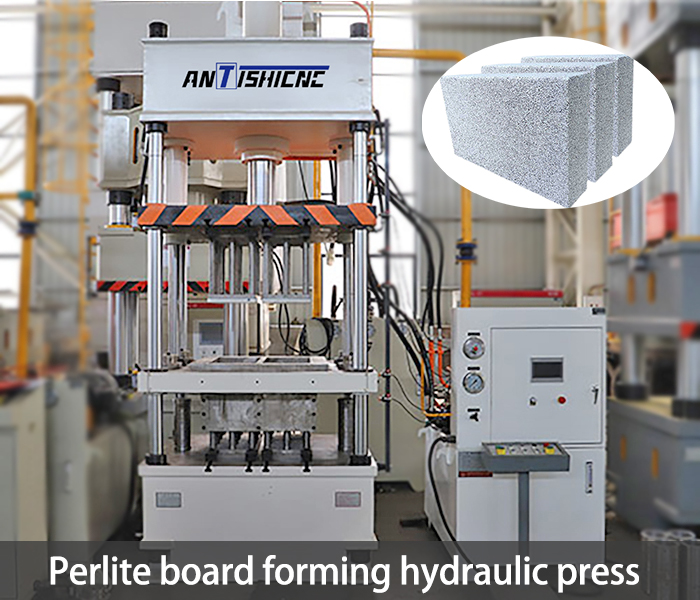

Shanghai ANTISHICNC is a professional manufacturer of hydraulic press machines and can provide customized service. The perlite sheet molding hydraulic press machine produced by Shanghai Anticipation adopts PLC plus touch screen control mode, with pointing and semi-automatic functions. High production efficiency, high safety, well received by customers. For example, the following 100 tons four-beam four-column hydraulic press machine.

100 tons of four beams and four columns of hydraulic press machine by the host and the control mechanism of the two parts, through the pipeline and electrical equipment linked to form a total, the host part includes the body, cylinder, limit range mechanism, mold frame and so on. The control mechanism consists of hydraulic pump station, electrical box, operating table.

1.Machine structure

The main machine of 100 tons four-beam four-column hydraulic press machine adopts four-beam four-column structure, the structural beam adopts high-quality steel plate structure, with four columns as the pillars, and the upper crossbeam and the worktable are located at the two ends respectively. The movable crossbeam and floating crossbeam are located in the center, which are guided by the columns and slide up and down. The upper crossbeam, movable crossbeam, floating crossbeam and lower beam of the main machine have been tempered and artificially aged accordingly. The main parts of the machine body have been analyzed by computer finite element analysis and have high strength and rigidity, which can ensure the smoothness and precision of the whole machine when working.

2.Cylinder

The cylinder body is forged by No.45 steel, the main cylinder body is fixed in the mouth of the upper crossbeam by the cylinder port flange and high-strength bolts, the lower end of the piston rod is connected by a flange, and the screw is connected with the slider, the head of the piston is made of casting for guiding, the head of the piston has seals in the opposite direction, and there are O-type seals in the piston rod, and there is a dust ring on the flange of the cylinder port, which ensures the dust-proofing of the piston rod.

3.Stroke limiting device

The position of main cylinder, lower cylinder and demolding cylinder are controlled by wire displacement encoder, and the required position can be set on the touch screen, such as the height of product bottom feeding, product side feeding, demolding height, and so on.

4.Mold frame mold

This equipment mold frame mold is installed in the working space of the equipment, the mold is divided into upper mold, lower mold and mold cavity, the upper mold is fixed on the upper movable beam, the lower fixed punch is installed on the fixed beam, the lower floating punch is installed on the lower movable beam, the mold cavity is installed on the mold cavity beam. The molding parameters of the product can be adjusted on the mold frame: loading height, product thickness, demolding height and other parameters.

5.Hydraulic system

Hydraulic station consists of oil tank, high and low pressure gear pump set, integrated valve set, hydraulic oil, filter, air filter and cooler.

| Description | 100T |

| Slider stroke (mm) | 800 |

| System pressure (Mpa) | 25 |

| Nominal pressure (KN) | 1000 |

| Maximum headroom (mm) | 1700 |

| Effective area of working table (mm) | 1100*1100 |

Remark: The above parameters are for reference only, the actual parameters of the machine please refer to the technical program of Shanghai ANTISHICNC.

If you have perlite sheet forming processing needs too, welcome to consult Shanghai ANTS Machine Equipment co., ltd. We have rich experience in manufacturing and using hydraulic press machine machine machines and can provide you with professional technical support.