Steel wood door embossing machine, also known as door plate embossing machine, door surface embossing machine, deep embossing hydraulic machine, is the main mechanical equipment for steel wood door production, suitable for steel wood door, anti-theft door, indoor door, big iron door, fire door and other door plate embossing molding, as well as steel plate calibration, leveling, stretching and other processes. So what are the working principle and characteristics of the steel door embossing hydraulic press machine?

Working Principle:

The steel wood door embossing machine generates high pressure oil pressure through the hydraulic system, which acts on the mold on the working table. At this time, the door surface to be processed inside the mold will be squeezed by the high pressure, so as to form patterns and textures on the door surface corresponding to the mold. Specific steps include placing the material to be embossed on the working table of the embossing machine, adjusting the position and fixtures, selecting and installing a suitable mold, and then activating the pressure system to cause the mold to descend and apply pressure to emboss the pattern onto the surface of the material.

Features:

1. Sturdy structure: the steel wood door embossing machine adopts six cylinders, eight columns and three beams structure, this design makes the machine more stable when working, and it can withstand more pressure, so as to ensure the clarity of the embossing effect.

2. Flexible operation: the machine is equipped with PLC system, supporting automatic, semi-automatic and manual operation modes. Users can set and adjust the parameters through the touch screen, making the operation more convenient and flexible.

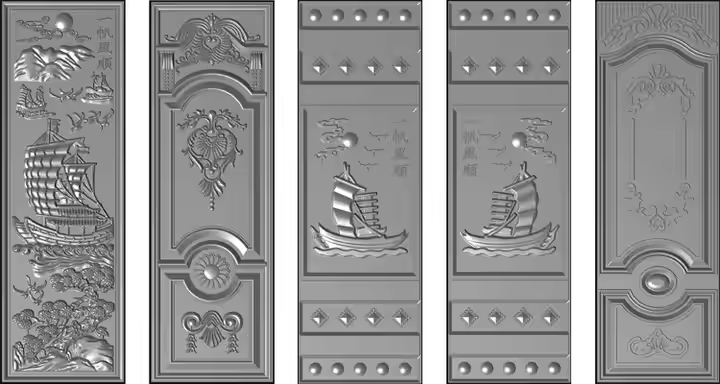

3. Clear embossing: the steel door embossing machine can realize double-action embossing, clear pattern and strong sense of three-dimensionality, which can meet the embossing needs of various door panels.

4.Energy saving and environmental protection: optional servo system, energy saving and noise reduction, in line with the environmental requirements of modern industrial production.

Shanghai ANTISHICNCi is a professional manufacturer of hydraulic press machine. The steel door embossing machine produced by Shanghai ANTISHICNC has the advantages of fast, safe and reliable, energy saving, beautiful products, low cost, etc., which is highly praised by customers. For example, the following 3600 tons hydraulic press machine.

3600 tons of steel and wood door embossing machine is a security doors, steel doors, interior doors stamping molding door embossing special hydraulic press machine, this machine is used for the production of 0.8mm ~ 3mm thick steel and wood door panels. 3600 tons of steel and wood door embossing machine machine body adopts a three-beam and eight-pillar structure, economical and practical, the hydraulic control of the cartridge valves integrated system to reduce the leakage point, reliable operation, long service life, can achieve the fixed-pressure and fixed-range two types of molding process, with a holding pressure delay function, the working pressure stroke can be adjusted within the specified range of operation. Forming process, with pressure preservation delay function, the working pressure stroke can be adjusted within the specified range, the use of button centralized control, can realize manual, semi-automatic, automatic three kinds of operation.

| Description | Unit | YQ78-3600T | |

| Nominal force | KN | 36000 | |

| Maximum fluid pressure | MPa | 31.5 | |

| Return force | KN | 630X2 | |

| Slide stroke | mm | 400 | |

| Return stroke | mm | 450 | |

| Maximum opening height | mm | 500 | |

| Slide | ldle speed | mm/s | 150 |

| Working speed | mm/s | 5-10 | |

| Return speed | mm/s | 80 | |

| Working table size | Left and right | mm | 1500 |

| Front and rear | mm | 2500 | |

| Ordinary control motor power | KW | 22X2 | |

| Servo control motor power | KW | 32 | |

Remark: The above parameters are for reference only, the actual parameters of the machine please refer to the technical program of Shanghai ANTISHICNC.

If you have steel wood door embossing forming processing needs too, welcome to consult Shanghai ANTS Machine Equipment co., ltd. We have rich experience in manufacturing and using hydraulic press machine machine and can provide you with professional technical support.