CNC milling machines play an important role in the automotive manufacturing industry. It can efficiently complete the production of key components, providing unparalleled precision and flexibility in automobile manufacturing. Some typical applications of CNC milling machines in the automotive manufacturing industry are introduced below.

1. Engine system

①Cylinders: High precision CNC milling machines machine cylinders to ensure optimum combustion and efficient engine performance. Milling machines are unique in their ability to achieve precise dimensions and superior performance Surface finishes reduce friction and wear, which are critical to the life and reliability of engine systems.

|

|

②Pistons: Milling machines are the preferred choice for pistons because of their ability to maintain the precise tolerances and high-quality surface finishes that are critical to achieving optimum compression ratios. This precision is critical for fuel efficiency and overall engine performance, making milling machines ideal for piston manufacturing.

|

|

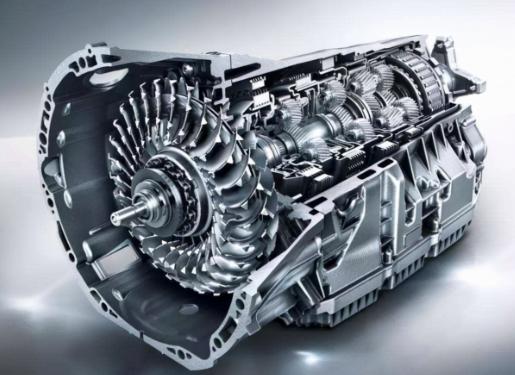

2. Transmission system

①Gearbox: The gearbox is a complex marvel that owes its smooth power transitions to fine milling precision, emphasizing seamless interaction of drivetrain components and longer service life.

|

|

②Clutch Housings: The CNC milling machine’s proficiency in handling robust materials to produce uniform, accurate components is critical to the manufacture of clutch housings. The resulting structural integrity and perfect alignment are critical to extending the life of the clutch system and minimizing wear.

|

|

3. Suspension System

①Suspension Arms: The precision and high structural integrity provided by suspension arm milling machines is critical. This manufacturing process ensures vehicle stability and seamless handling, providing a driving experience marked by control and smoothness.

|

|

②Shock absorbers: With the CNC milling machine, perfect surface finishes and tight tolerances can be achieved on the shock absorbers, which are essential for optimal damping and overall stability of the vehicle, thus improving ride comfort.

|

|

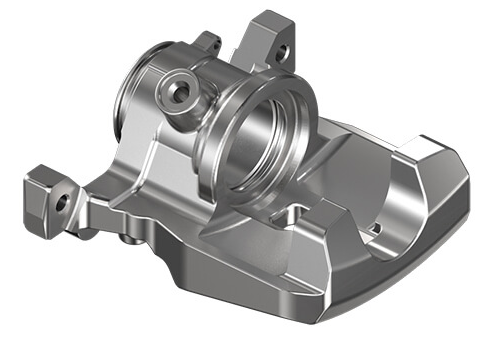

4. Braking system

Brake calipers and discs: The CNC milling machine gives the discs precise dimensions and smooth surfaces, which are essential features for effective heat dissipation and reliable braking performance, thus enhancing the safety of the vehicle.

|

|

5. Fuel system

①Fuel Injectors: The role of CNC milling machines in the molding of fuel injectors is critical. The resulting accuracy of fuel atomization is a milestone in combustion efficiency and plays a vital role in reducing emissions and improving fuel economy.

|

|

②Fuel Rails: The superior surface finish and precise dimensions of fuel rails achieved through milling are critical to maintaining accurate fuel pressure and flow, optimizing fuel delivery, and ensuring consistent engine performance.

|

|

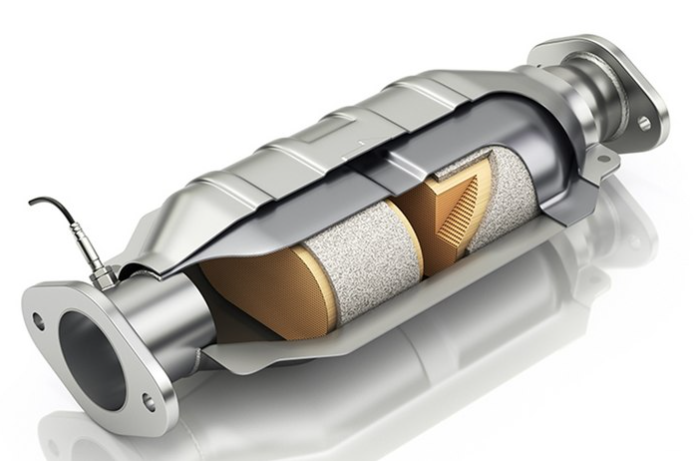

6.Exhaust system

①Exhaust Manifolds: The flexibility of CNC milling machines at high temperatures creates durable exhaust manifolds that promote efficient flow of exhaust gases, emphasizing enhanced engine performance.

|

|

②Catalytic Converters: The precision of CNC milling machines is crucial in the manufacture of catalytic converters. It ensures optimal placement of the catalyst, maximizes the conversion of harmful gases and emphasizes environmental protection.

|

|

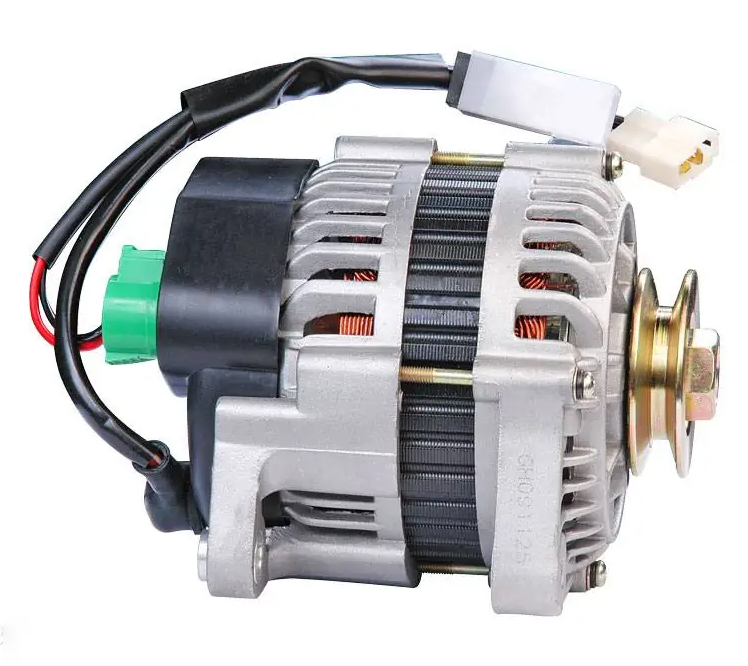

7. Electrical system

①Alternators: The mastery of CNC milling machines is evident in the manufacture of alternators. Its contribution to the seamless conversion of mechanical to electrical energy is integral to maintaining the reliability of vehicle electronics.

|

|

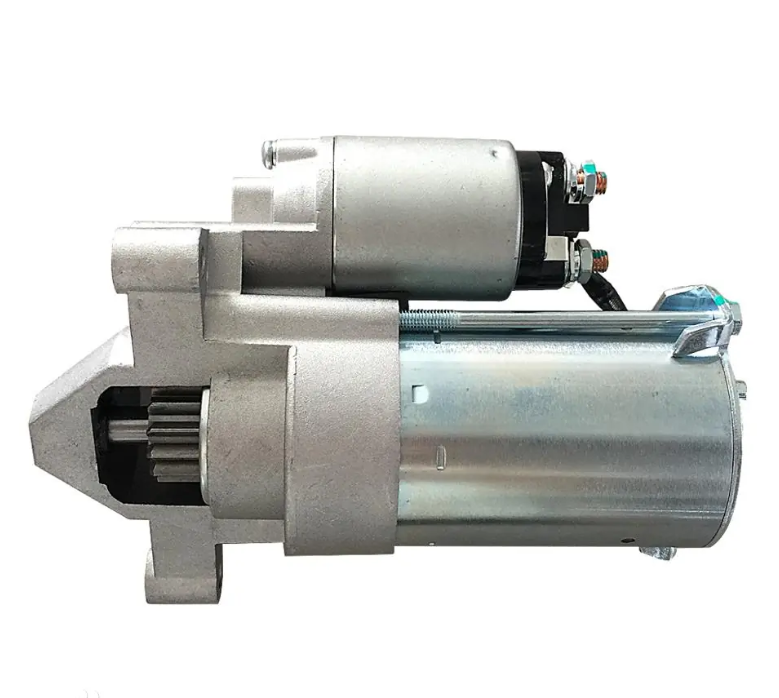

②Starter: The starter is precision molded on a milling machine, demonstrating seamless part interaction and ensuring reliability when starting the vehicle.

|

|

8. Carbody and frame

①Chassis: The strength and durability of the chassis, achieved through CNC milling machine, emphasizes its indispensable role in providing a resilient base for the vehicle.

|

|

②Car body panels: Known for their intricate design and precise dimensions achieved by milling machines, body panels are central to a vehicle’s aesthetic appeal and aerodynamic efficiency.

|

|

9.Internal component

Instrument panel elements, headlamp housings and tail lamp assemblies: Instrument Panel Elements, Headlamp Housings and Tail Lamp Assemblies machined on CNC milling machines are highly accurate and precise, and play a vital role in enhancing overall road safety.

|

|

Shanghai ANTS Machine Equipment Co., Ltd. provide a variety of milling machine, CNC milling machine, can support customized services, if necessary, you can consult our technical staff.

Keywords: Milling machine, CNC milling machine