In order to avoid disputes caused by damage or moisture during transport due to packaging problems, ANTISHICNC will choose packaging materials and packaging methods that meet the requirements according to the characteristics of the machine and the mode of transport to ensure the safety and integrity of the machine. The standards are as follows:

1.We will select the appropriate packing box, choosing the suitable one according to the weight, outline dimensions and weight distribution of the machine to be packed. If the packing box needs to meet the hoisting and inserting conditions, the bottom support must be strong enough!

For general goods with a weight of less than 4 tons, a thick plywood bottom support can be selected.

For goods with a weight between 4 tons and 8 tons, a channel steel integrally welded bottom support can be chosen.

For goods with a weight exceeding 8 tons, a log bottom support should be used.

Note: Adequate full-size support woods will also be added on the top of the packing box to ensure sufficient supporting force during hoisting and avoid the hoisting rope from damaging the packing box.

|

|

|

|

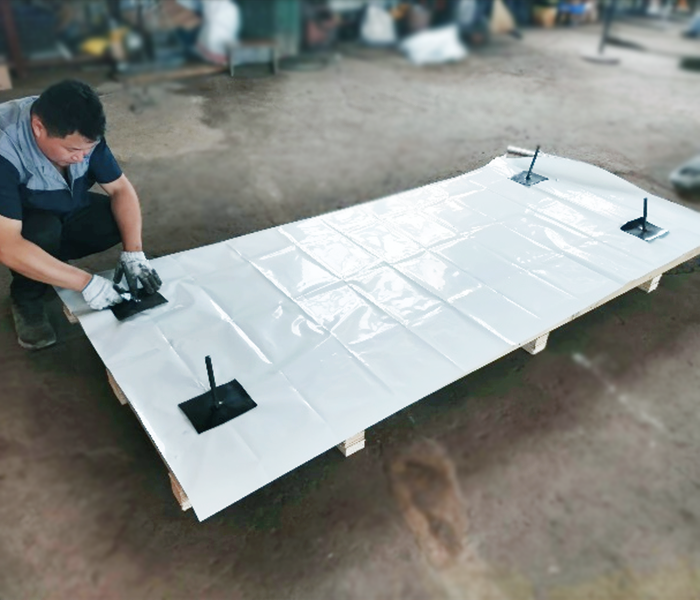

2.We will also install fixed iron hooks, as shown in the figure. If the positions of the fixed iron hooks do not match the wooden squares of the bottom support, we will add fixed wooden squares to ensure sufficient strength.

|

|

3.After the fixed iron hooks are installed, lay the flat wooden boards. Each iron hook should be threaded through a waterproof rubber sleeve, then cover it with an aluminum foil cover, and finally add another layer of waterproof rubber sleeve to ensure that during machine transportation, water vapor will not enter the packaging interior from the openings of the iron hooks and cause rust on the machine.

|

|

|

|

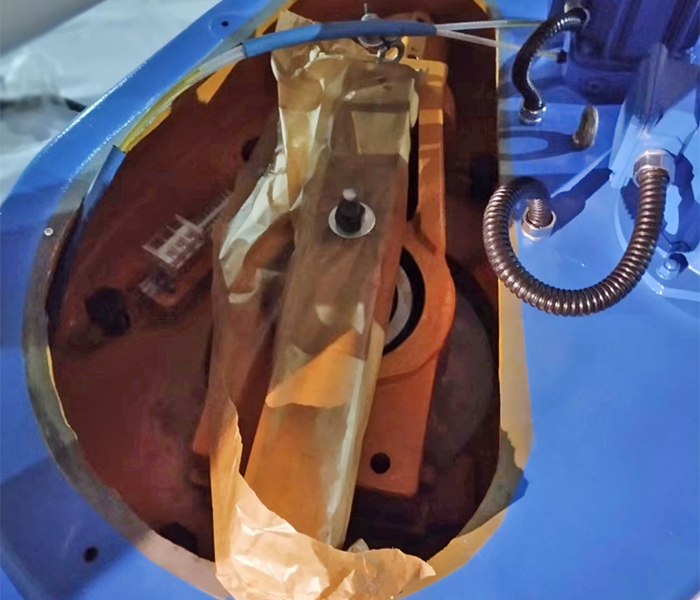

4.Lift the machine to the designated position and lock the fixing nuts. Add wooden blocks on the side to prevent the machine from moving sideways. Note that at the parts where pressure bars need to be added, the pressure bars must not directly touch the goods. Wooden squares or rubber sheets should be padded. In addition, the rubber sheets should also be wrapped with oil paper. Wooden squares or rubber sheets must be added at the stacked parts of the goods to prevent the parts from being damaged due to collisions between the machines during transportation.

|

|

|

5.For non-painted surfaces, anti-rust oil will be applied. The anti-rust oil selected will be a product with good anti-rust effect and easy removal.

|

6.Fix the disassembled scattered parts and the parts that follow the machine, and place them properly in the wooden packing box. Check the random spare parts according to the packing list and contract to ensure the integrity of the machine.

|

|

7.Protect the sharp corners of the machine and packaging in advance to avoid puncturing the aluminum foil cover when vacuuming.

|

8.Cover the aluminum foil cover and heat seal it for vacuuming. Since there are many sharp

corners on machine tools and equipment and complete vacuum cannot be achieved, we will try our best to reduce the moisture contained in the air inside the packaging, thereby reducing the rust of the equipment caused by the residual moisture inside the packaging during machine transportation.

|

|

9.Fix the aluminum foil cover with adhesive tape to prevent the aluminum foil cover from being torn when closing the box.

|

10.After packaging is completed, shipping marks will be pasted on the wooden box as required by ANTISHICNC and the shipping marks will be laminated to ensure no damage during transportation. We will also mark the forklift side. If the machine cannot be inverted, a mark will be printed on the wooden box.

|

|

If there are any questions or need for further clarification regarding the packaging or its contents, please do not hesitate to reach out to our ANTISHICNC team. We are available to provide assistance and support at any time.

We wish for a smooth and successful transportation of the machine and look forward to your satisfaction upon receipt.

You can adjust and modify these according to the specific context and requirements of your packaging instructions.

SHANGHAI ANTS MACHINE EQUIPMENT CO.,LTD is a professional suppliers for the metalworking and metal-forming equipment located in Shanghai China for 20 years already. We offers all kinds of lathe machine, milling machine, grinding machine,EDM machine, drilling machines such as radial drilling machines, cnc drilling machines and vertical drilling machines. Metal bandsaw machine, Metal bending machine such as plate rolling, plate bender, press brake and plate cutting machines.

More products for the tubes and pipes bending machines are also available. For more products information, please take a visit our site www.antsmachine.com

With professional employees, good working ethics, we ANTISHICNC team will offer you satisifed machinery. You can reach to our team via contact@antsmachine.com or whatsapp:+8619534031668 Thank you for your support!