Daily maintenance is crucial for the stable operation and extended service life of conventional lathes. Timely cleaning and lubrication help ensure machining accuracy and reduce unexpected downtime. As referenced in related materials, keeping the machine clean and performing regular maintenance enables the lathe to operate “without failure.”This article outlines the importance of daily maintenance, specific maintenance procedures, as well as key points for periodic servicing and common precautions to keep in mind.

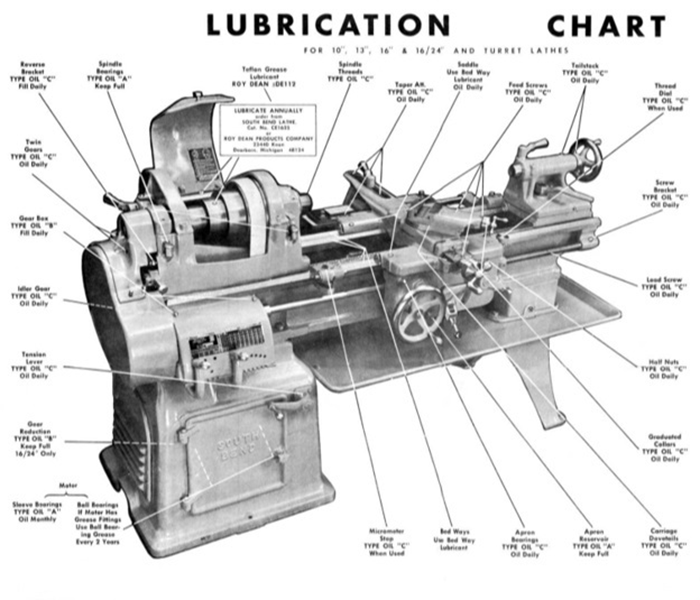

All motion pairs of the lathe — such as the bed guideways, spindle bearings, lead screw, gearbox, and tool post slide surfaces — must be properly lubricated. Before and after each startup, the oil level in the automatic lubrication system’s tank should be checked and replenished as needed. According to the maintenance schedule, the bed guideways must be lubricated daily to ensure that an oil film forms on the sliding surfaces. Common lubricants include machine-specific slideway oil and grease; appropriate lubricants should be selected according to the machine’s manual. Mixing different types of lubricants or using non-standard products should be avoided.

Cleaning and Maintenance

Cleaning is a fundamental step in daily maintenance. During operation, chips and debris should be removed promptly to keep the worktable and bed guideways clean. After finishing work, use a brush and vacuum cleaner to clean up chips. Do not use a high-pressure air gun to blow away chips, as this may cause injury or force debris into bearings and other small gaps. When machining materials that generate fine dust, such as cast iron, special care should be taken to thoroughly wipe the guideways to prevent dust from mixing with lubricant, which can lead to abrasive wear.

Inspection and Maintenance

During maintenance, it is also necessary to inspect the machine’s key components: check whether the lead screw guard, tailstock, and chuck are securely fastened; check the tension of belts and chains; check the levels of coolant and lubricating oil; check the temperature of the electrical cabinet, the grounding condition, and whether the safety door limit switches are functioning properly. Additionally, clean the chip trough and coolant filter screen.

Key Points for Periodic Maintenance

In addition to daily maintenance, more in-depth servicing should be performed on a regular basis. A full inspection and maintenance should be carried out weekly: thoroughly clean the machine’s exterior; add or replace lubricating oil for the bed guideways, tailstock lead screw, tool post, and gearbox; after lubrication, check for leaks and ensure the amount of oil or grease is appropriate.

Every month, inspect and clean the automatic lubrication oil tank and filters, and replace lubrication filter elements as necessary. Check that oil pipelines and valves are clear and unobstructed to prevent clogging. Additionally, clean the coolant tank, clear the filter screens, and replace the coolant. Inspect the lead screw for backlash and check the wear condition of guideways; make adjustments or repairs if necessary.

Maintenance Precautions and Common Mistakes

Always disconnect the power supply and lock the machine before performing maintenance. When replacing the chuck or adjusting the headstock, use a guard plate to protect the guideways.

Never use compressed air to blow off chips; instead, use a soft brush and vacuum cleaner.

Do not place tools or other objects on the guideways or bed surface to avoid dropping and damaging the machine.

Lubricating oil must meet the specified requirements—do not mix different oils or use low-quality lubricants.

The machine should be kept dry and protected against rust; after cleaning, thoroughly dry all moisture and apply anti-rust oil.

Regularly inspect safety devices such as protective doors and emergency stop buttons.

the C Series Horizontal Conventional Lathes

Our C Series multifunctional universal lathe integrates a variety of common turning processes such as external and internal turning, taper turning, and facing. It also features drilling, reaming, and oil groove cutting functions, allowing multi-step integrated machining of part contours and inner holes with a single machine. The precise threading system supports metric, inch, module, and diametral pitch threads, meeting the diverse threading requirements of industries such as automotive, mold making, and instrumentation.

Designed with an enlarged spindle bore, it can directly process large-diameter bar stock, eliminating the need for cumbersome pre-processing. The dual-feed system allows easy switching between metric and imperial units, flexibly adapting to the technical standards of different countries and regions. Equipped with both hand brake and foot brake options, operators can easily control the machine during high-speed cutting or heavy-load machining. The electrical system can be configured according to customer needs with voltages of 220V, 380V, or 420V and frequencies of 50Hz or 60Hz, ensuring global compatibility and greatly enhancing the equipment’s suitability and reliability in international markets.

This lathe features a sturdy structure, stable operation, and consistent precision, making it the ideal choice for manufacturers pursuing high efficiency, high accuracy, and flexible machining capabilities.

This series of conventional lathes is widely used in industries such as machinery manufacturing, metal processing, maintenance services, and mold making. It is suitable for batch processing of medium- and small-sized parts as well as single-piece production, with outstanding performance in areas including:

Machining and repair of engine components, shafts, and flange plates;

Manufacturing and repair of parts for automobiles, motorcycles, and various power machinery;

Precision machining of metal components, equipment parts, and mold bases.