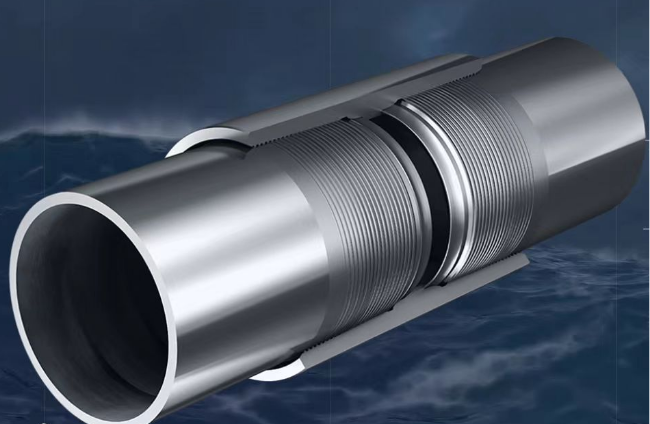

Oil pipes are widely used in the petroleum industry. When extracting oil wells, natural gas and oil can be transported through oil pipes to ensure the safety of natural gas and oil transportation. Oil pipes are mainly connected through joint headbands, and there are threads on both ends of the joint headbands. Therefore, the quality of the threads on the outside of the oil pipe directly affects the connection effect of the oil pipe.

Oil pipe threads are basically tapered threads. The taper of most threads is 1:16. The thread size mainly includes two categories: 10 teeth and 8 teeth per inch. The thread length is also divided into long round buckle and short round buckle. Compared with ordinary threads, oil pipe threads have detachability and higher connection strength, and have greater requirements for quality and technical operation. After completing the thread processing of the oil pipe, testing is required. One of the more important test items is the pressure test method. When performing the pressure test, the thread grease used must meet the relevant requirements, and there is no water seepage problem under the minimum hydraulic test pressure after tightening. The quality of this type of oil pipe thread is qualified. In petroleum mechanical processing, the processing efficiency and quality of oil pipe threads are important links. When the processing characteristics and processing conditions are different, the quality of oil pipe threads will also vary. During processing, longer steel pipes are required for threading. For a long time, the oil pipe thread processing enterprises in my country’s petroleum industry have mainly used mechanical pipe thread lathes as thread processing equipment. In the process of rapid development of modern science and technology, the modernization of CNC pipe thread lathes has been improved accordingly, so that the efficiency and quality of thread processing have been continuously improved. The QK series CNC pipe thread CNC lathes produced by Baoji Machine Tool Co., Ltd. are undoubtedly synonymous with quality and efficiency. QK series CNC pipe thread lathes are widely used in oil fields, geology, mining, chemical industry and agricultural drainage and irrigation departments; they are mainly used to process internal and external threads of pipe workpieces. They also have the functions of ordinary CNC lathes and can perform external processing on workpieces such as shafts and discs. Processing of circles, inner holes and end faces; this series of machine tools uses dual pneumatic chucks to clamp workpieces, and the CNC system automatic control system is very efficient for the petroleum industry in processing and repairing drill pipes, joints, casings and other workpieces. At the same time CNC pipe thread lathes can also be used in geological exploration, mineral mining, chemical smelting, pipe network construction, machinery manufacturing, shipbuilding and other industries.

The optional pipe thread auxiliary feeder can improve the processing efficiency, that is, the one-to-two method, to avoid turning around and lifting the workpiece again, or after processing one end, turning around and lifting to process the other end. For specific application cases, please consult the business personnel of Shanghai Antis Machinery Equipment Co., Ltd.

The processing objects of pipe thread machine tools are API standard oil, casing and pipe coupling various buckle threads. Special threads for oil, casing and pipe couplings other than API standards. API standard drill pipe, drill pipe joints, drill collars, etc. Various diameters are large, the length of the workpiece is long, and only the workpieces at both ends are processed.