What is CNC Swiss lathe machining?

The CNC swiss lathe machine first originated in Switzerland, so it is called the Swiss CNC machine tool. Originally used for the processing of tiny instrument parts, it is a type of precision manufacturing that can produce very small parts quickly and accurately. Where the parts are formed by a lathe operated by a CNC unit, which rotates the part in a radial motion while cutting it. This type of specialized tool cutting allows the machine to perform multiple operations at once in less time.

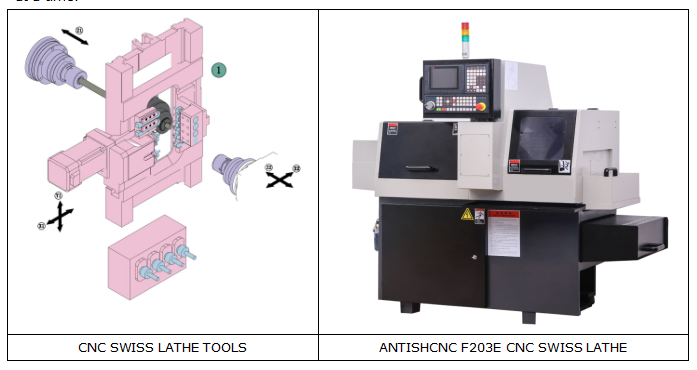

The turning range centers on micromachining in the diameter range from 1 mm to 4 mm, as well as complex B-axis milling and eccentric applications with diameters up to 26 mm. Offers boring, boring, knurling, turning and milling functions, as well as external thread cutting, tapping, rolling and single-point threading. A variety of materials can be processed, from stainless steel to titanium, aluminum, and even plastic. Our machines also feature auto-loading capabilities for high-volume runs.

Introduction to the working principle of Micro Precision CNC lathe (Swiss lathe)

The cnc swiss lathe machine works by feeding bar stock through a guide bushing that firmly supports the material as it is fed into the tooling area of the machine. In addition, only the part of the bar being processed enters the processing area, which means that the material is tightly held in place, allowing the overall processing stability and precision to reach a relatively high level. With traditional CNC lathes, the workpiece is usually rotated rapidly in a fixed position and held firmly at one or both ends. In contrast, with a Swiss lathe (CNC lathe), the workpiece can both rotate and move back and forth along the Z-axis while various tools cut the part. Additionally, Swiss lathes can perform multiple operations in multiple areas simultaneously, whereas conventional lathes typically can only perform one operation instruction at a time.

While CNC machines are traditionally used to machine turned parts such as screws, CNC machines can also produce complex parts with no turned surfaces at all.

Advantages of center lathe processing

The advantage of the rotary lathe is that it is both accurate and fast. It can maintain very tight machining tolerances, making it ideal for applications that require the same measurements all the time. Simple parts can also be produced with short cycle times, as little as 10 seconds depending on the part. Much like 5-axis machining, parts can be rotated along 5 different axes to achieve the most precise cuts on each part.

Usual processing accuracy: dimensional tolerance can reach ±0.01MM; one-time processing concentricity 0.005MM; one-time processing parallelism //0.01MM; single-side verticality ⊥0.01MM.

The main processing materials can be: carbon steel, manganese steel, alloy steel, tool steel, high-speed steel, 45 Q235, SKD61, SKD11, 304, 316, 303, 400 stainless steel, aluminum alloy, copper, iron, aluminum parts, Saigang, Standard and non-standard precision machining of ABS acrylic, plexiglass, PC, POM, PVC, PP, nylon, bakelite, plastic, Teflon, epoxy board, plastic glue and other materials.

The CNC Swiss lathe machining machines provided by Shanghai Ants Machinery Equipment Co., Ltd. are widely used in the fields of dental parts, mobile phone equipment accessories, automobile parts, precision shaft parts, gear medical accessories and other fields. If you need consultation or proofing, please contact our sales staff. Contact email contact@antsmachine.com

Tags: CNC centering machine, Swiss lathe, new energy charging head processing, dental parts processingmachines