1. Selection of the object to be processed

Before determining the purchase object, we must first clarify the object to be processed. Generally speaking, parts with the following characteristics are suitable for processing in a machining center: Multi-process intensive workpieces refer to a workpiece that needs to be processed with many tools. Reproducible workpieces are suitable for single-piece small batch production. Small batch refers to 1-100 pieces, the number of each batch is not large, but it needs to be repeatedly produced. In addition, even if the shape and size of the workpieces are different, they are similar workpieces, and it is easy to realize the parts of the group processing technology. For complex-shaped parts, molds, aviation parts and other complex-shaped workpieces, various special-shaped parts can be processed on the machining center with the help of automatic programming technology.

2. Selection of machine specifications

According to the size of the workpiece to be processed, the table size of the required machine tool and the stroke of the three linear coordinate systems are determined accordingly. The size of the worktable should ensure that the workpiece can be smoothly clamped on it, and the processing size must be within each coordinate stroke. In addition, the tool change space and the limitations of each coordinate interference area must be considered.

3. Selection of machine tool accuracy

According to the machining accuracy requirements of the workpiece, the user selects the machine tool of the corresponding accuracy level, and the mass-produced parts, the actual machining accuracy value may be 1.5-2 times the positioning accuracy. Ordinary machine tools process workpieces with 8-level precision in batches, and precision machine tools can process 5-6 levels of accuracy, but there must be constant temperature and other process conditions, so precision machine tools are strictly used and the price is high.

4. Selection of tool magazine capacity

The manufacturer of the machining center usually sets up 2-3 different capacity tool magazines for the machine tool of the same specification. When the user selects, he can determine the required number according to the process analysis results of the workpiece to be processed, usually only one part is required. The number of tools required in one setup determines the capacity of the tool magazine, because when another part is processed, the tools need to be rearranged, otherwise the tool management is complicated and prone to errors.

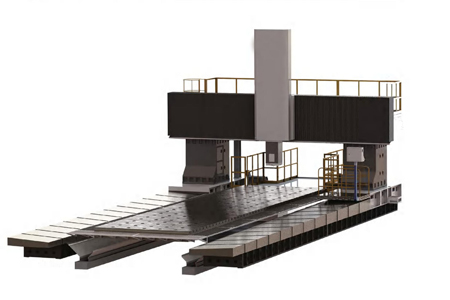

5. Selection of machine tool selection functions and accessories

When selecting a machining center (gantry milling machine), in addition to the basic functions and basic parts, there are also functions and accessories that users can choose according to their own requirements, called selection functions and selection accessories. With the development of numerical control technology, there are more and more contents to choose from, and the proportion of its constituent price in the host is also increasing. Therefore, it is not economical to choose a large number of accessories for unclear purposes. The so-called “preparedness” Ordering guides is essentially a waste. Therefore, a comprehensive analysis should be made when selecting and ordering, and long-term factors should also be properly considered.

The selection function is mainly for the numerical control system. It does not increase much for the price, but for the functions that bring many conveniences to use, it should be properly configured and complete. For the accessories that can be shared by multiple machine tools, you can consider one machine for multiple purposes. But it must be considered that the interface is generic.

Want to know more about the process of the product? ANTISHI has a mature team of engineers who are very familiar with heat treatment processing and can handle product processing problems including packaging technical problems. In addition, during the installation and design process, our engineer team can be assigned to solve problems on the spot, to the greatest extent possible. Helping producers to carry out convenient and efficient production has always been the goal of our company.