First, What is CNC EDM Drilling machine?

CNC piercing machine is a kind of equipment that uses digital control system to control the electric spark discharge between the electrode wire (or electrode tube) and the workpiece, so as to process the workpiece by piercing. It is a kind of EDM machine tool, through the principle of discharge corrosion, the workpiece material will be gradually etched, and finally form the required hole.

Second, the working principle of CNC EDM Drilling machine

When the CNC EDM Drilling machine is working, the electrode (electrode wire or electrode tube) and the workpiece are first connected to the two poles of the pulse power supply. When the gap between the electrode and the workpiece is small to a certain extent, the pulse power supply releases a high-energy pulse voltage, which makes the medium in the gap (generally the working fluid, such as special oil for EDM or water-based working fluid) to be ionised and punctured, forming a discharge channel. In this channel, an extremely high temperature (up to 10,000 – 12,000 ℃) and a strong pressure will be generated instantly. This high-temperature and high-pressure environment causes the local material on the surface of the workpiece to rapidly melt and vaporise, and be washed away by the working fluid. As the pulses are repeated, the electrode is fed into the workpiece, thus gradually etching the workpiece and eventually forming a through-hole. In this process, the CNC system precisely controls the movement trajectory of the electrode, the feeding speed, the discharge parameters, etc., to ensure the precision and quality of the perforation.

Third, the processing advantages of CNC EDM Drilling machine

| High Precision Machining |

| With excellent performance in machining accuracy, its positioning accuracy can reach ±0.01mm – ±0.05mm, and the hole diameter and depth can be precisely controlled, which can meet the stringent requirements of high-precision hole machining, such as those in the manufacture of moulds and dies. |

| Complex shaped holes can be machined |

| Extremely complex shaped holes can be machined, whether they are shaped holes, such as square, oval, or slanted holes, with the help of CNC programming can be easily realised, providing strong support for the manufacture of special mechanical parts and structural components. |

| Unrestricted by material hardness |

| The machining is not limited by material hardness, and based on the EDM erosion principle, it is possible to pierce holes efficiently even in materials with extremely high hardness (e.g. HRC60 – HRC70 hardened mould steels), such as cemented carbide and hardened steels. |

| Good machining stability |

| The CNC system monitors and flexibly adjusts parameters such as discharge current, voltage, electrode feed rate, etc., and the working fluid circulating system continuously purifies the working fluid and flushes away the erosion products, ensuring a stable and trouble-free machining process. |

| High degree of automation |

| The machine can be processed automatically according to the preset procedure, and the operator only needs to input the processing parameters, and it can be integrated with automatic loading and unloading devices and other automated equipment, which shows its advantages in mass production and effectively improves the production efficiency and reduces the labour cost. |

Fourth, case study –MS-DC430C CNC EDM Drilling machine

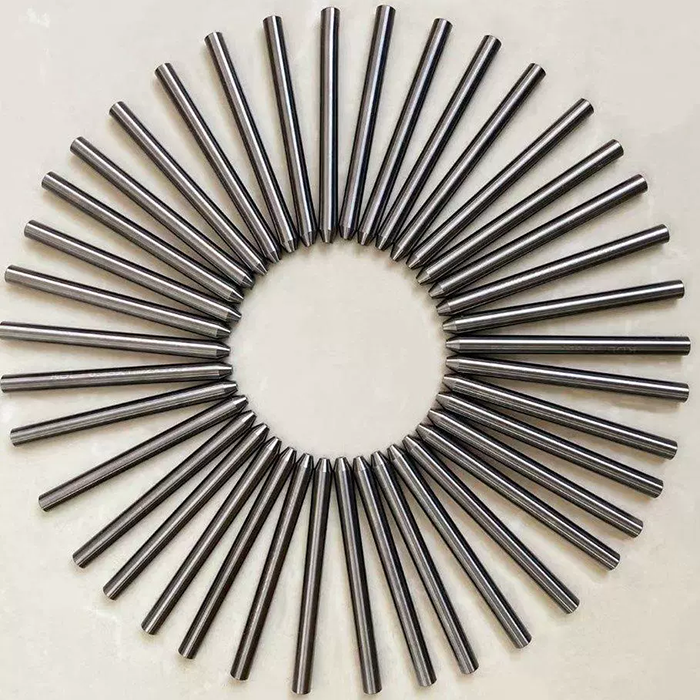

Recently, we received a consultation from an Italian manufacturer of waterjet abrasive nozzle, he needs to drill holes for waterjet abrasive nozzle, the material is tungsten steel, the inner diameter of the hole needs to be 0.7-1.2mm, the length is 60-150mm, according to the needs of customers, our company’s engineers matched a DC430C CNC EDM Drilling machine for customers. Can meet the needs of customers.

The technical parameters are as follows:

| Description | MS-DC430C |

| Electrode diameter(mm) | Φ0.3-Φ3.0 |

| W axis/ Machine head travel(mm) | 250 |

| Z axis/ Spindle servo travel(mm) | 380 |

| Max. speed of spindle(mm) | 1500 |

| Spindle rotation speed(rpm) | 0-200adjustable |

| Worktable size(mm) | 440*320 |

| X*Y travel(mm) | 400*300 |

| Max distance from guide to working table(mm) | 300 |

| Max. worktable load (kg) | 300 |

| Overall dimension of machine(W*L*H) | 1200*1200*2100 |

| Machine weight (kg) | 750 |

| Positioning accuracyX,Y(mm) | X.Y≤0.04/300 |

| Repositioning accuracy XY(mm) | X.Y≤0.04/300 |

| Max feed speed XY (mm/min) | ≤1000 |

Our engineers will work with you to match the most suitable solution.