The grinder can be regarded as a beautician in the machining industry. After various grindings, the workpiece looks more beautiful. The CNC grinding machine greatly improves the efficiency and precision of the surface grinding of the workpiece by using CNC technology, and can realize the batch, quality and centralized processing of simple to complex parts. It can not only process materials with higher hardness, but also perform high-precision and strong grinding and grinding with very small surface roughness. It has an indelible position in the machining industry. So for this beautician, how to choose to make the machining in your factory more powerful? In fact, it mainly starts from these aspects! Is the use of CNC grinder suitable? In fact, CNC grinders are divided into many types, including CNC surface grinders, CNC external cylindrical grinders, CNC internal cylindrical grinders and other types. As a user, the most important thing is to choose the right equipment according to the workpieces to be processed and the processing characteristics of various CNC grinders. When choosing equipment, the most important thing is to pay attention to the characteristics of specialization, versatility and simplification. Don’t pursue diverse functions, which will only appear fancy, and in the end, various problems will appear in a short time or many functions will not be used at all. The so-called specialization means that you need to find a professional. Therefore, try to choose specialized, simplified, and highly versatile equipment. In other words, don’t be omnipotent, but be specific.

Is the structure of the CNC grinding machine product reasonable?

So how to see whether the structure of the product is reasonable? In fact, whether the structure is reasonable, for laymen, it is generally to see whether the appearance is pleasing to the eye, whether it is symmetrical, whether there are many burrs and edges, whether it has enough reinforcement ribs, whether the staggered reinforcement ribs have structural symmetry, whether the layout is uniform, and whether the plate ribs are thick enough. Generally speaking, the plate ribs should look thick and strong and can withstand greater gravity, and don’t look like the kind that bends when pressed. In addition, when the weight of the whole machine reaches above the industry average, you can look at the basic parameters of the same type of machine tools to have a psychological idea. Because the stability of the bed structure is crucial to the processing accuracy and stability.

Is the CNC system a mainstream brand?

The more powerful CNC systems are Fanuc, Siemens, Heidenhain, Mazak, Mitsubishi, Rexroth, etc. Generally speaking, the mainstream CNC systems of big brands are relatively stable, and of course the price is definitely relatively expensive. But no matter what, when looking at the system, you must pay attention to whether the system has reduced configuration, because whether each system function is open is related to the price. When choosing, it is best to compare with the parameters of the bed with high cost performance. Through comparison, you will find some clues.

Whether the structure and material of the CNC grinder are exquisite

Speaking of reduction, it is actually reflected in the structure and material of the equipment because a qualified and standardized product design is more exquisite in the structural processing and material selection, as well as the wall thickness and heat treatment methods of the parts. It is necessary to strictly calculate the material force, calculate the tensile strength, calculate the material deformation, calculate the stability of the parts, etc. In fact, these are not so easy for a layman to see, so you can guide them to tell you about these things through asking, and judge his confidence in this regard through his response to the answer. Use more doubts to question, see how he explains, and whether the explanation is smooth.

Check whether the product inspection certificate is complete

Generally speaking, each bed will have a product inspection certificate, which is marked with various parameters and precisions as well as the standard parameters stipulated by the state. These parameters can be compared to see the factory precision and whether it meets your needs.

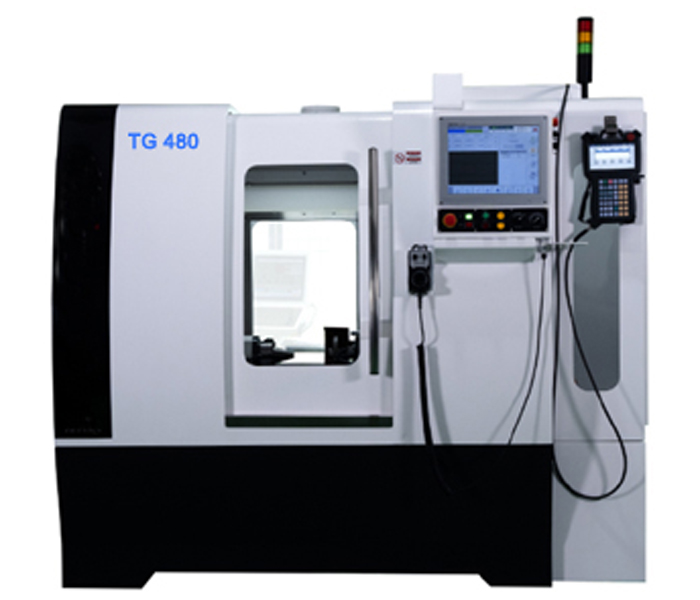

ANTISHI CNC grinding machine have reasonable structures and exquisite materials. There are many different professional CNC grinder products to choose from, such as 4-Axis TG480 Four-Axis Linkage CNC Tool Grinder, 5-Axis TG560 & TG580 CNC Tool Grinding Machine, H3 High Precision CNC Step Grinding Machine, etc.

|

|

|

4-Axis TG480 Four-Axis Linkage CNC Tool Grinder, four-axis four-linkage CNC tool grinder focuses on the production of: standard milling cutters, aluminum processing cutters, acrylic milling cutters, chamfering cutters, and tap slotting. The machine tool adopts: multi-station grinding and multi-grinding wheel group grinding technology. After years of practical use, it can better ensure the quality of tool production and greatly improve tool production efficiency. The front and back doors are open to facilitate unlimited debugging and maintenance of the machine tool, and the fully enclosed protective cover meets production safety. All axes use fully imported servo motors and screw guides, with high precision and resolution to ensure the high production quality and efficiency of the machine tool.