1、 Poor machining accuracy of machining center parts

Generally, the feeding dynamics between the axes are not adjusted properly according to the error during installation and adjustment, or the transmission chains of the machine tool axes have changed after wear (such as the change of lead screw clearance, pitch error, axial displacement, etc.). It can be solved by readjusting and modifying the clearance compensation amount. When the dynamic tracking error is too large and alarm occurs, check whether the servo motor speed is too high. Check whether the position detection element is good. Check whether the position feedback cable connector is in good contact; Whether the corresponding analog output latch and gain potentiometer are in good condition; Whether the corresponding servo drive device is normal.

2、 Poor machining accuracy caused by overshoot of CNC machining center

The acceleration and deceleration time may be too short, so the speed change time can be appropriately extended; It may also be that the connection between the servo motor and the lead screw is loose or the rigidity is too poor, and the gain of the position ring can be appropriately reduced.

3、 Roundness out of tolerance when two shafts are linked

1. Axial deformation of circle

This deformation may be caused by mechanical failure to adjust properly. Poor positioning accuracy of the shaft or improper compensation of the lead screw clearance will result in roundness error when the image limit is exceeded.

2. Oblique ellipse error (ellipse in 45 degree direction)

At this time, first check the position deviation value of each axis. If the deviation is too large, adjust the gain of the position loop to eliminate it. Then check whether the interface board of the rotary driver or inductosyn is properly adjusted, and check whether the clearance of the mechanical transmission pair is too large and whether the clearance compensation is appropriate.

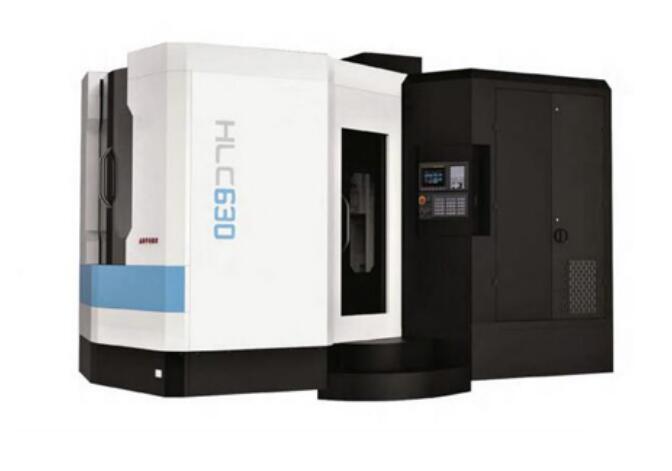

Equipment selection: The machining accuracy error is closely related to the selected machine tool equipment. ANTISHICNC manufactures various types of CNC machine tools, including machine tools and machining centers for sawing, turning, milling, grinding, drilling, grooving and forming machines, and EDM machines, among others. Using high-end CNC technology, with high-precision motor and strict design, it has high machining accuracy and long service life. ANTISHICNC machine tools have a wide range of types, rich models, and very cost-effective, and are sold in many countries.