Aerospace products have very high requirements for structural design, function, performance, product quality, and reliability, and many new materials and structures will be used, so the processing requirements are also relatively high. The high precision and high efficiency of five-axis machining technology are in line with the requirements of aerospace products. The following will introduce several typical applications of five-axis CNC machining in the aerospace field.

1. Aircraft components

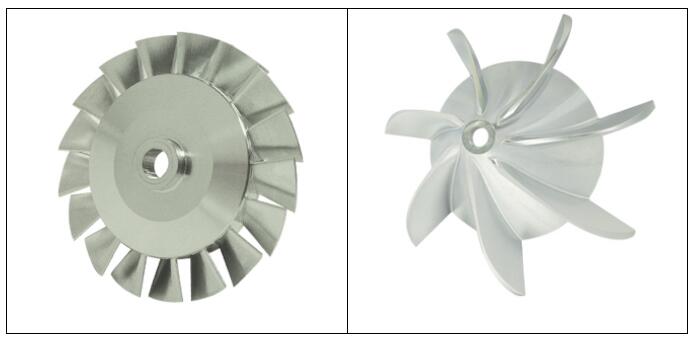

Various parts of aircraft such as engine blades, turbine rotors, front and rear fuselages, wings, etc. need to be manufactured using five-axis CNC machining technology. This technology can realize high-precision machining of complex curved shapes and ensure the accuracy and quality of parts.

2. Spacecraft structure

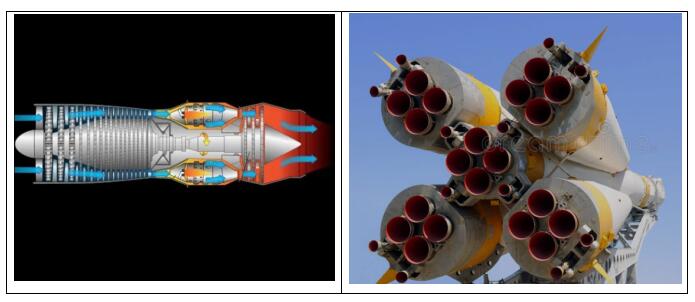

The structure of spacecraft is composed of many metal plates, and the processing of these metal plates requires the use of five-axis CNC machining technology. Five-axis CNC machining can realize high-precision machining of ultra-thin metal sheets, so as to meet the structural requirements of spacecraft.

3. Aviation engine

The aero-engine is the heart of the aircraft, and its manufacturing requires the use of high-precision processing technology. Five-axis CNC machining can achieve high-precision machining of complex curved surface shapes such as engine blades and turbine rotors, thereby improving engine performance and stability.

4. Space propulsion system

The aerospace propulsion system is one of the key parts to realize the operation of the spacecraft, and its manufacture requires high-precision machining technology. Five-axis CNC machining can realize the machining of complex curved shapes involved in the aerospace propulsion system, such as combustion chambers, nozzles, and so on.

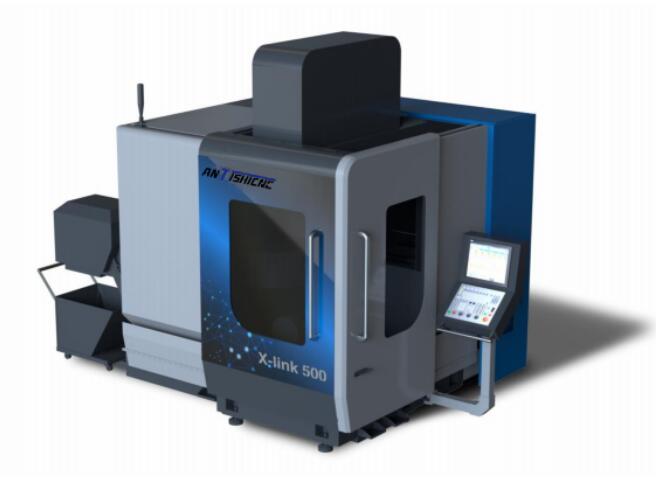

The five-axis linkage CNC machine produced by Shanghai ANTS Machine Equipment Co., Ltd. have been fully functionally tested for 48 hours after assembly. They have passed various strict inspection procedures to ensure that the geometric accuracy, processing performance, and various functions of the machine tools meet the factory requirements. And it can ensure long-term stability. It has the characteristics of high precision and high efficiency. Well received by our customers.

Shanghai ANTS Machine Equipment Co., Ltd. provide a variety of walking machine CNC lathe, automatic lathe, can support customized services, if necessary, you can consult our technical staff.

Keywords: five-axis machine technology, five-axis CNC machine, CNC lathe machine