What is Swiss-type Automatic Lathe and Knife Machine?

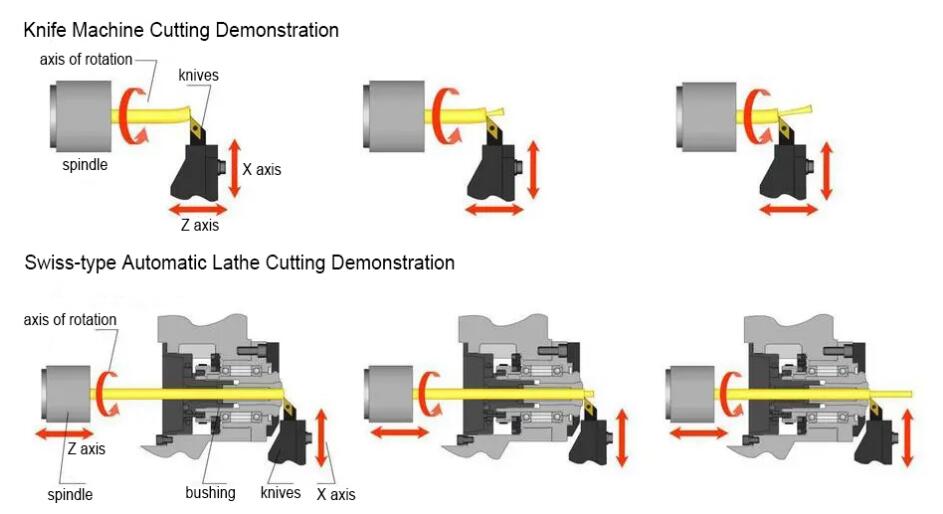

Both Swiss-type automatic lathe and CNC cutting machine belong to CNC horizontal lathe. The traditional CNC lathe is mainly based on the cutting mode, which is called the cutting lathe. The single clamping position of the product remains unchanged, and multiple feedings cannot be performed. The product can only be processed by the rotation of the spindle C axis and the Z/X/Y movement of the tool post. For long-axis products, only the thimble can be used to push the end face and additionally install the follower bracket, but in the end, it is difficult to achieve the ideal accuracy and complete the product process requirements at one time.

Swiss-type automatic lathe, the full name is moving CNC lathe, referred to as moving machine, scientific name definition: spindle box mobile CNC lathe. The heart-moving mode of the lathe originated in Switzerland and is known as the Swiss precision automatic lathe internationally. Most of the lathes are turned in the form of slitting, so they are also called slitting CNC lathes in the Chinese market. Because the standard configuration of CNC lathes are equipped with side power heads, they can complete the milling process, also known as lathes.

Both Swiss-type automatic lathe and CNC cutting machine belong to CNC horizontal lathe. The traditional CNC lathe is mainly based on the cutting mode, which is called the cutting lathe. The single clamping position of the product remains unchanged, and multiple feedings cannot be performed. The product can only be processed by the rotation of the spindle C axis and the Z/X/Y movement of the tool post. For long-axis products, only the thimble can be used to push the end face and additionally install the follower bracket, but in the end, it is difficult to achieve the ideal accuracy and complete the product process requirements at one time.

The Swiss-type automatic lathe is that the tool is always in a fixed position, and the product is processed by the forward and backward movement of the Z axis of the main shaft and the rotation of the C axis, and supports multiple feeding. In theory, the length of a single product can reach the largest single material supported by the feeder. The maximum length.

Therefore, compared with the tool-type machine tool, when the machine tool is turned, the bar is fed axially through the center guide sleeve, and the cutting point of the tool is close to the mouth end of the guide sleeve, which has good rigidity and eliminates the bar material under the cutting pressure of the tool. Deformation ensures the accuracy of the parts, and the machining of slender shaft parts has absolute advantages.

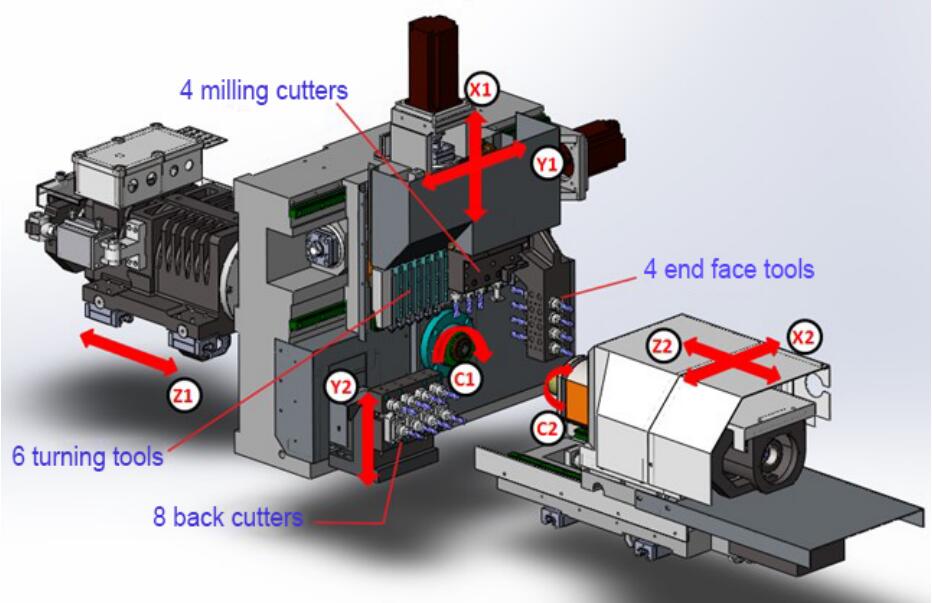

The Swiss-type automatic lathe is generally used to process small parts such as bars, large batches, and parts that need to be processed at one time. Since the structure of the Swiss-type automatic lathe is different from that of the traditional CNC lathe, the processing efficiency and machining accuracy of the centering machine are higher than those of the CNC lathe. The machine adopts two-axis arrangement of tools. This design greatly saves the processing cycle time. By shortening the tool exchange time between the arrangement of tools and the opposite tool table, the overlapping functions of multiple tool tables and effective axis movement of thread chips are realized. , The direct spindle indexing function during secondary processing shortens the idle time.

The Swiss-type automatic lathe can also be equipped with an automatic feeding device to realize fully automatic production of a single machine tool, reducing labor costs and defective products in the production process, and can be used to produce large quantities of precision shaft parts. Generally, the feeder passes the bar through the through hole of the main shaft, and the spring chuck is automatically clamped. If the part has a long overhang, it needs to be equipped with a center. If the tail needs to be processed, a second spindle is required. If it is also necessary to process equally divided holes, a driven tool holder and spindle indexing are required.

As long as it is a part that can be processed by a Swiss-type automatic lathe, its machining accuracy, processing speed, and cutting machine are difficult to compare!

The main advantages are as follows:

1: The spindle can turn parts with a length of more than 200mm in one clamping without stopping. If you are turning a part with a length of 5mm, you can turn the tool and the center, but you can turn 20~30 parts in one go before you need to stop and feed.

2: When cutting, the center lathe will always fix the nearest position of the material, so the rigidity is very good. After you think about your lathe clamping the parts, the tool will stick to the clamping position for a few mm to turn, and the rigidity will be good. to what extent.

3: The centering machine is a combination of turning and milling, and the complexity of one-time processing and forming is not comparable to that of the old-fashioned automatic car, which is commonly known as the cam machine lathe. And now the more advanced CNC automatic lathe, we call it a center lathe or a slitting lathe. Mainly, the spindle Z moves forward and backward, and the knife can move in X and Y, which can realize three-dimensional processing and one-time forming. In the past, it was basically imported, but the price was extremely high, and now China has its own mature technology.