Metal cutting Circular saw machine using metal circular saw blade as a cutting tool, the use of hydraulic methods, for all types of metal materials for sawing processing, belonging to the CNC automatic type of high-end precision cut-off processing equipment; high-speed circular saw machine’s main components: by the head + all kinds of feeding control system (feeding, hydraulic, electrical, spray device, lubrication, etc. system) + frame, etc., the main accessories are: gearboxes, main motors, ball screw, hydraulic pumps, solenoid valves, drives, PLCs, inverters, magnetic brakes, etc., the production of circular saws produced by different manufacturers is different, but in general there will not be a major change in the specific reference to the physical object.

The main role of the high-speed metal circular sawing machine is used for various types of metal materials cut-off processing, which is characterized by fast sawing speed, cut off the surface smooth and flat (verticality to ± 5 silk), high efficiency (cost savings), automatic counting, automatic material separation and so on.

Generally speaking, the PLC-controlled automatic high-speed circular saw machine has the following characteristics:

1.High-speed sawing with high efficiency

The HY-75NC Metal Circular Sawing Machine manufactured by ANTS Machine Equipment Co., Ltd. adopts high-speed sawing technology, which is capable of cutting medium carbon steel bars of different diameters in a short period of time. Whether the bar is 15mm, 40mm, or 75mm outside diameter, the cycle time can be completed between 4-14 seconds. Compared with the traditional CNC band sawing machine, the cutting efficiency of HY-75NC metal circular sawing machine is 5-10 times higher, which greatly improves productivity.

2.High-precision sawing accuracy

HY-75NC metal circular sawing machine with an integral casting base and linear guide to ensure the smooth and reliable operation of the equipment. Precision gearbox spindle drive and spindle stabilization system improve sawing accuracy and reduce saw blade loss. The automatic feeding and sawing feed system adopt high-performance servo motors and high-precision ball screws to ensure the precision transmission of feeding and sawing without backlash. These advanced technologies ensure the high precision cutting of HY-75NC Metal Circular Sawing Machine, which meets the needs of various precision processing.

3.Economic, low-cost operation

The running cost of the HY series metal circular saw machine is relatively low. The circular saw blade adopts super hard material TCT, which ensures the sawing precision and service life. At the same time, the selection of an imported spray lubrication cooling system improves the service life of the circular saw blade and reduces the cost of sawing. The moving parts of the equipment adopt an automatic lubrication system, which reduces the wear and tear of the equipment and prolongs the service life of the equipment. In addition, the HY series metal circular saw machine can be operated by one person to operate multiple machines, effectively reducing labor costs, and the overall cost of cutting is reduced by 1/3-1/2.

4.Automation ontrol system

HY-75NC metal circular sawing machine adopts the most advanced Siemens, Mitsubishi CNC intelligent data cutting main control system and humanized software interface combined to achieve simple operation and interactive touch screen. The advanced automatic material preparation frame cooperates with the main control system to realize the function of automatic material preparation and no material straight stop. The whole process from material preparation to sawing is fully automated, improving productivity and efficiency.

5.Intelligent material rack

The material rack is the place where the materials that need to be sawed are placed. If you do not pay attention to the material rack, it is likely to increase your working time, especially when production is busy, this is very fatal!

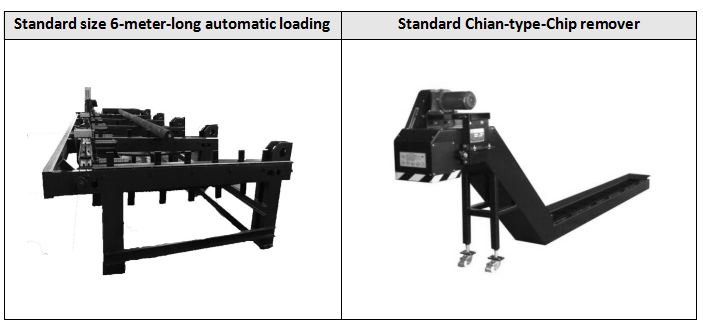

Many companies don’t pay much attention to it, and many still use ordinary flat material racks. However, sometimes it is found that when the material is turned over after sawing, many pieces of this kind of material rack will appear together, or they will not be turned over at all. , which can easily affect the sawing progress of the equipment, and seriously affect the service life of the equipment (if the connection is not timely, the equipment will frequently stop and shut down, resulting in unstable performance). Do not underestimate some small factors, most problems The occurrences are caused by small and inconspicuous problems. Paying attention to details will make your business easier! The circular saw machine of ANTS Machine Equipment Co., Ltd. adopts an intelligent feeding rack structure, which can automatically feed materials according to the situation of sawing materials. The intelligent feeding system consists of several parts such as a storage rack, a material distribution mechanism, and an adjustment mechanism. The material distribution mechanism is powered by a hydraulic cylinder. After manually adjusting the material specifications, the feeding system can complete the automatic feeding action under the control of the host machine. This will double the sawing efficiency!

Metal circular saw machine is a very important tool that is widely used in various industries. Whether it is mechanical cutting, car repair, or construction, this equipment provides efficient and precise cutting work. Here are some use cases of metal circular saw machines:

Mechanical processing industry

In the field of mechanical processing, metal circular saw machines are widely used in product production processes such as automotive parts manufacturing and aerospace manufacturing. By combining circular saw blades with different specifications and properties with saw machines, mechanical processing manufacturers can easily complete the cutting of different materials. In addition, the circular saw machine can also flexibly adjust the cutting speed and cutting angle according to processing needs to improve the accuracy and efficiency of automated processing.

Automobile repair industry

In the field of automobile maintenance, metal circular saw machines also have important application value. The metal circular saw machine can quickly cut accessories of various materials and shapes to meet the needs of automobile repair and maintenance. By using a gold circular saw machine, automobile maintenance workers can easily complete precise cutting work in a short time, improve work efficiency, and provide customers with fast and high-quality services.

Construction industry

In the construction industry, steel, aluminum and other metal products are indispensable building materials. Metal circular saws can realize high-speed precision cutting, and to ensure that the cutting surface is smooth and flat, to meet the requirements of the construction work for precision and performance. Of course, in the process of construction work also often need to carry out angle cutting, some saws can also have angle control function, to meet the complex cutting needs of the building.

Industrial processes

In addition to the above applications, metal circular saws can be used in numerous production processes. Circular saws can help companies to increase production rates and quality, especially in the cutting and machining of large parts. This type of equipment can greatly reduce labor costs, lower production costs and increase productivity.

Overall, metal circular saw machine is widely used in materials, manufacturing, industrial agriculture and other industries, and has an important role in improving production efficiency and reducing labor costs. In the future development, with the continuous development of science and technology and innovation, metal circular saw machine will also continue to upgrade and evolve, for the industries for more and better service.

If you have questions about whether you are suitable for high-speed circular sawing machine, or confused about how to select the right metal circular sawing machine, please feel free to contact our company’s sales engineers.

Website www.antsmachine.cn

E-mail: contact@antsmachin.com

Tags: metal circular saw machine, high speed sawing, Steel bar sawing machines