As a company with many years of experience in grinding machines, whether it is surface grinding machines, cylindrical grinding machines, internal grinding machines, etc., the Shanghai ANTS team strives to keep up with the times and constantly improve the quality of our grinding machines, hoping to create a machine that meets the individual needs of our customers.

We all know that in the past the commonly used grinding machines are only one processing mode, if you encounter a product that requires two processing modes or even a variety of processing modes, a single mode of the machine to a certain extent will not be able to meet the processing needs of the workpiece, and at the same time because of the factors of multi-processing needs, which leads to customers needing more than one piece of equipment for the work, which leads to a series of cost increases: time costs, capital expenditure, energy loss, etc.. This will lead to a series of cost increases: time costs, capital expenditure, energy loss and so on.

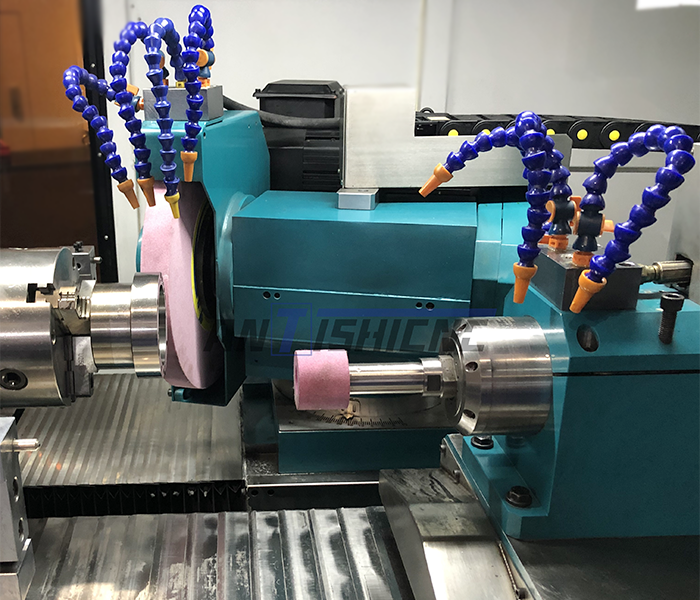

Is there a machine that can perform multiple machining modes? Of course there is. The new CG45 internal and external cylindrical grinding machine from Anticipate Shanghai is such a machine that can perform multiple machining modes.

Compared to conventional grinding machines, the CG45’s machine guideways maintain optimum accuracy over long periods of time due to the machine’s lubrication system, which constantly supplies oil to the guideways and precision ball screws and ensures their longevity. We also have a better cooling system for better heat dissipation.

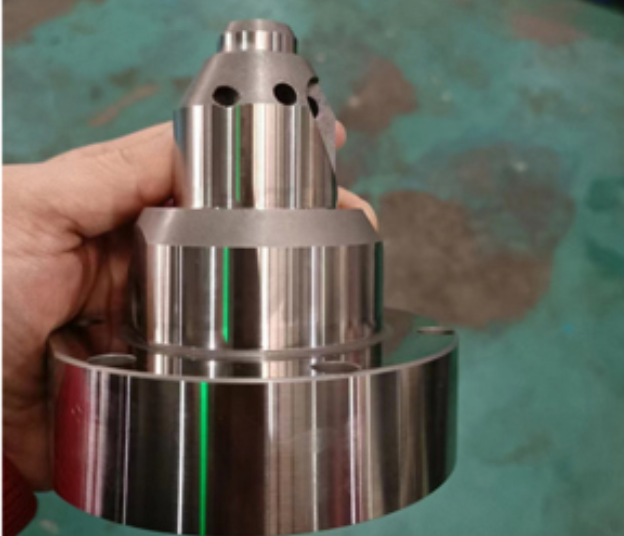

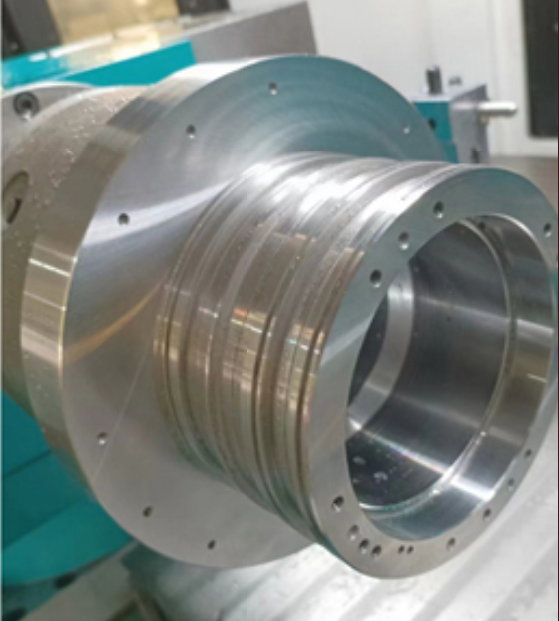

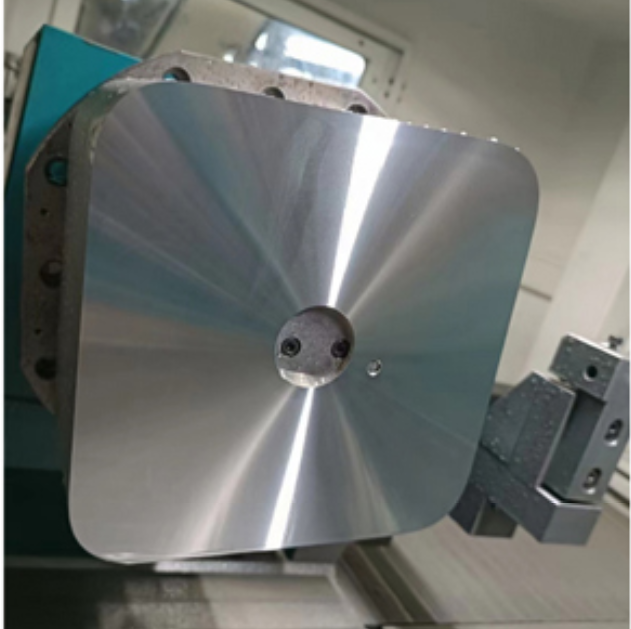

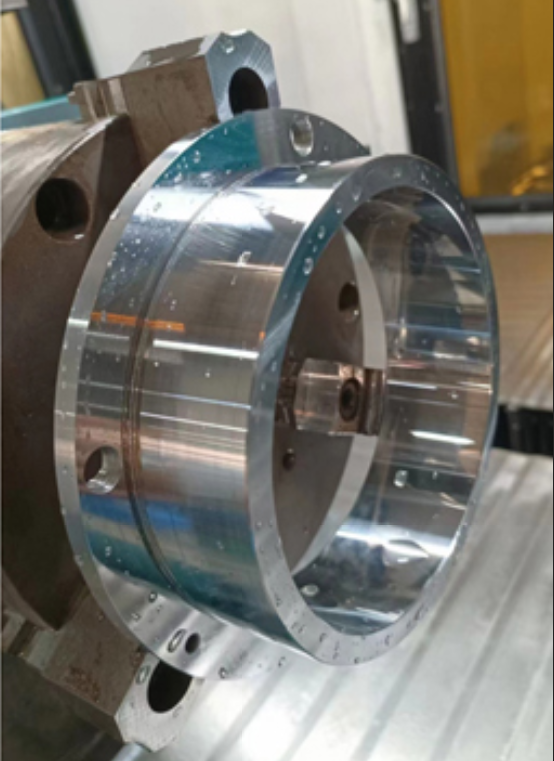

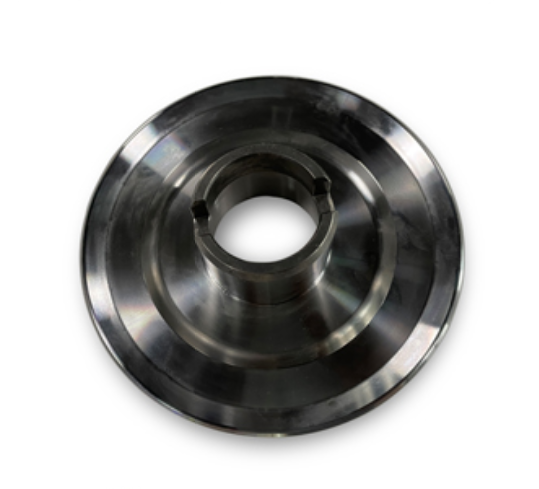

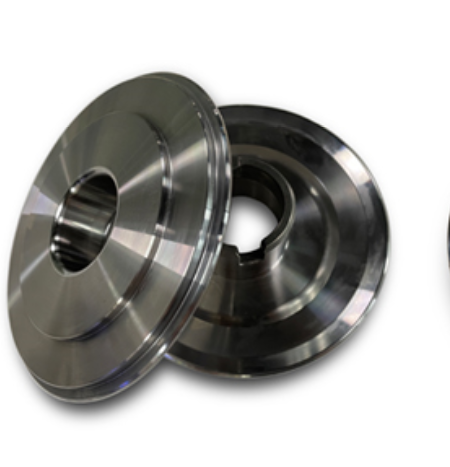

Our machine has a unique advantage in processing, can achieve the internal circle, internal cone, external circle, external cone, end face grinding, a collection of a variety of working modes of the equipment, to a large extent, can reduce production costs and improve production efficiency.

With the diversification and individualisation of market demand, the manufacturing industry has an increasing demand for the versatility of machine tools. Traditional single-function machine tools have been unable to meet the needs of complex workpiece processing, while the composite grinding machine combines a variety of grinding modes, can be completed on the same machine tool for a variety of processing tasks. This versatility allows companies to respond more flexibly to changes in market demand, increasing productivity and flexibility.

If you need to process complex and high-precision workpieces such as hydraulic parts, bearings, etc., then I believe that Shanghai ANTS’s composite grinder CG45 is a good choice.

| Machinable components | |

|

|

|

|

|

|

|

|

*Pictures are for reference only

| High precision CNC compound grinding machine | |

|

|

|

|

If you have other needs you can refer to our website our website: https://www.antsmachine.com/

Keywords: Compound grinding machine, CNC compound grinder, Multifunctional grinder, Integrated grinder, Cylindrical grinder, Internal grinder, High precision grinder