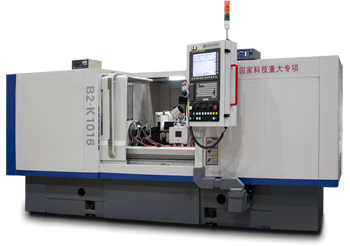

CNC camshaft grinder

B2-K1016 CNC Camshaft Grinding Machine is a high-end CNC machine tool designed and developed by our company for camshaft grinding. The machine tool applies production-type CNC grinding machine design method and CNC non-circular grinding technology to realize CNC linkage grinding of cam profile, with strong processing flexibility, simple and reliable operation, and has the characteristics of high rigidity, high efficiency, and high reliability.

The machine tool adopts CNC two-axis interpolation linkage, fully closed-loop feedback control of the grinding wheel feed axis (X axis) and workpiece rotary axis (C axis), realizes the CNC precision positioning movement of the non-circular cam surface, and completely solves the traditional machining by mode. The machine tool has the disadvantages of poor processing flexibility, difficult profiling and complicated maintenance. The linear speed of CBN grinding wheel is 120m/s. Both C-axis and X-axis adopt internationally advanced direct drive technology. They are mainly used for mass precision machining of cam profiles of internal combustion engine camshaft parts. The front side of the machine tool is a vertical plane without any adjustment. It is suitable for installing parts logistics transmission line without mutual interference, and it is the optimal equipment for production line. The machine tool complies with relevant national and international standards in terms of safety, environmental protection, and ergonomics.

1. The mechanical and electrical integration structure layout, overall protection, convenient maintenance and ergonomics requirements.

2. The CBN grinding wheel is directly driven by the static piezoelectric spindle, which has the characteristics of high rotation accuracy, good accuracy retention, and strong rigidity. The CBN grinding wheel has a linear speed of up to 120m/s and is equipped with a built-in dynamic balance system.

3. Three-axis linkage feed can be realized. The headstock (C axis) is directly driven by a torque motor, with a positioning accuracy of 0.002 degrees, and the grinding wheel frame (X axis) is directly driven by a linear motor, with good dynamic response, and the maximum speed can reach 40 m. /min, the worktable (Z axis) is driven by a servo motor, the minimum setting unit is 0.1μm, and the maximum fast forward speed can reach 20m/min.

4. The 120m/s CBN grinding wheel adopts diamond rollers to rest and is equipped with a sonar detector, which can ensure the precise rest of trace amounts and prolong the service life of the CBN grinding wheel; the rollers are directly driven by the electric spindle.

5. Imported advanced numerical control system with comprehensive control functions such as program conversion of grinding process, workpiece quality management, machine tool status monitoring, fault self-diagnosis and abnormal alarm, etc., menu-style interface input is simple and convenient.