In today’s competitive manufacturing landscape, efficiency and precision are key. A CNC Turn Mill Center combines the capabilities of turning and milling in a single machine, offering unmatched versatility and productivity. Whether you’re in aerospace, automotive, medical, or general machining, understanding the benefits and applications of a CNC turn mill center can help optimize your production process.

In this guide, we’ll explore:

1. What a CNC Turn Mill Center is

2. Key features and advantages

3. Industries that benefit from turn-mill machines

4. How to choose the right model

5. What is a CNC Turn Mill Center?

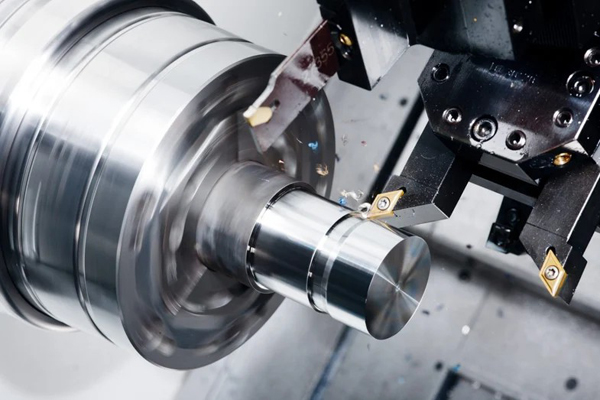

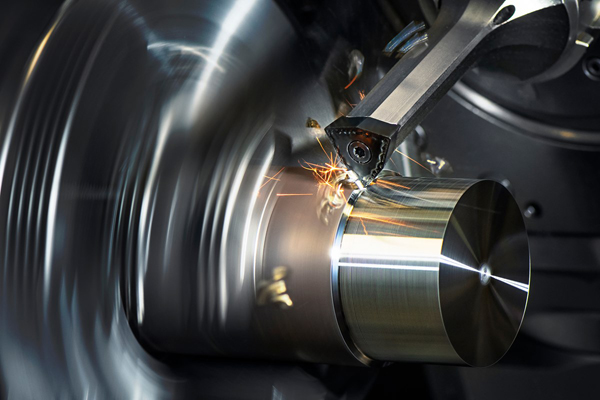

A CNC Turn Mill Center (also known as a multitasking machine or mill-turn center) is an advanced CNC machine that integrates turning (rotational cutting) and milling (linear cutting) operations into one system. This eliminates the need for multiple setups, reducing production time and improving accuracy.

How Does It Work?

Turning: The workpiece rotates while a stationary cutting tool shapes it.

Milling: A rotating cutting tool moves along multiple axes to machine complex features.

Live Tooling: Enables milling and drilling operations while the workpiece is stationary or rotating.

B-Axis Machining: Some models offer full 5-axis capabilities for intricate geometries.

Key Features of a CNC Turn Mill Center

Modern turn-mill centers come with advanced features that enhance productivity:

1. Multi-Axis Machining (5-Axis or More)

Allows simultaneous machining from multiple angles, reducing setup time.

Ideal for complex parts like turbine blades and medical implants.

2. Live Tooling

Enables milling, drilling, and tapping without transferring the workpiece to another machine.

3. Automatic Tool Changer (ATC)

Reduces downtime by quickly swapping tools during operations.

4. High-Speed Spindles

Supports both turning (main spindle) and milling (sub-spindle) at high RPMs.

5. Y-Axis Capability

Expands milling flexibility by allowing off-center machining.

6. Bar Feeder Integration

Automates loading for continuous production of small, precision parts.

Advantages of Using a CNC Turn Mill Center

✅ Reduced Setup Time

Combines turning and milling in one machine, minimizing part handling.

✅ Improved Accuracy

Eliminates repositioning errors since all operations are done in a single setup.

✅ Cost Efficiency

Lowers labor costs and reduces the need for multiple machines.

✅ Complex Part Machining

Capable of producing intricate geometries that would otherwise require multiple setups.

✅ Faster Production Cycles

Ideal for high-mix, low-volume (HMLV) and high-volume manufacturing.

Industries That Benefit from CNC Turn Mill Centers

1. Aerospace

Used for machining turbine components, landing gear, and structural parts with tight tolerances.

2. Automotive

Produces engine components, transmission parts, and precision shafts efficiently.

3. Medical

Manufactures surgical instruments, implants, and prosthetics with high precision.

4. Oil & Gas

Machines valves, fittings, and drilling components that require durability and precision.

5. Defense & Military

Used for gun barrels, missile components, and other high-strength parts.

6. General Machining & Job Shops

Ideal for prototyping and custom part production with quick turnaround times.

How to Choose the Right CNC Turn Mill Center

When selecting a turn-mill machine, consider the following factors:

1. Machine Size & Work Envelope

Ensure it accommodates your largest workpieces.

2. Number of Axes

3-axis vs. 5-axis: More axes allow for more complex geometries.

3. Spindle Speed & Power

Higher RPMs are needed for hard metals and fine finishes.

4. Tool Capacity

More tools mean fewer interruptions for tool changes.

5. Automation Options

Bar feeders, robotic loaders, and pallet changers enhance productivity.

6. Control System & Software

Look for user-friendly CNC controls (e.g., Fanuc, Siemens, Haas).

7. Budget & ROI

Balance upfront cost with long-term efficiency gains.

A CNC Turn Mill Center is a game-changer for manufacturers looking to improve precision, reduce cycle times, and cut costs. By integrating turning and milling into a single machine, businesses can streamline production and tackle complex parts with ease.

If you’re considering investing in a turn-mill machine, evaluate your production needs, part complexity, and budget to choose the best model for your operations.

Need expert advice on selecting a CNC turn mill center? Contact us today for a consultation!

Keywords: