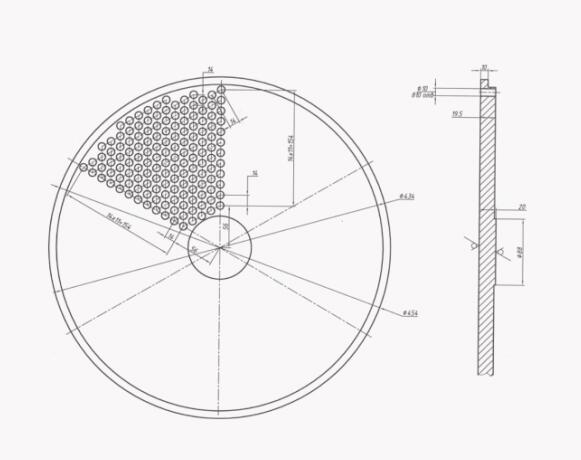

Recently, customers engaged in the production and manufacturing of pressure vessels came to us. They need a CNC drilling machine to process tube and plate parts. The maximum drilling diameter of the steel is required to be not less than 20 mm, the positioning accuracy is 0.06mm, and the repeatability is 0.03mm. The following is the customer’s workpiece drawings. :

Pressure vessel refers to a closed device that contains gas or liquid and carries a certain pressure. Pressure vessels are widely used and are mainly used in industry, civil and military industries. Among them, they are most used in the chemical industry and petrochemical industry. The pressure vessels used in the petrochemical industry alone account for about 50% of the total number of pressure vessels. In the chemical and petrochemical fields, pressure vessels are mainly used for processes such as heat transfer, mass transfer, and reaction, as well as for the storage and transportation of pressurized gases or liquefied gases. They are also widely used in other industrial and civil fields, such as air compression. machine. All types of special compressors and auxiliary equipment of refrigeration compressors (coolers, buffers, oil-water separators, gas storage tanks, evaporators, liquid coolant storage tanks, etc.) are pressure vessels.

After communicating with the customer, the customer believed that the most important thing for them was to maintain accuracy in the task, that is, precision. The work piece to be processed will be steel, and the customer needs to drill many holes on it. Based on customer feedback, the Shanghai ANTS technical team gave two matching solutions: the HD2016 economical model, and the PM3030 high-precision model.

|

HD2016 |

PM3030 |

| This machine is suitable for drilling on metal plates such as building steel structures, power towers, and petrochemical equipment. Adopt gantry structure. The X, Y and Z axes are driven by servo motors through precision ball screws. Automatic, precise and rapid positioning, and automatic drilling processing. Therefore, it greatly improves accuracy and speed. At the same time, rework and scratches caused by manual positioning or drilling errors are avoided. | This machine tool is a gantry mobile CNC high-speed drilling machine. It is mainly used for drilling and grooving work pieces such as tube sheets and flanges. It can use either internally cooled carbide drill bits or externally cooled twist drill bits. The two spindles can work simultaneously or independently, CNC controlled, easy to operate, and can achieve automated, high-precision, multi-scale, small and medium-sized batch production. |

|

|

Considering that the customer is engaged in the pressure vessel industry, which has high requirements for accuracy, our first recommended model is the PM3030. This model has high precision and a positioning accuracy of ±0.1mm. It is mainly used in the pressure vessel industry and can fully meet the requirements. The customer’s processing needs, but the minimum processing range is 3M. Compared with the customer’s work piece, the machine is relatively large. Therefore, based on the customer’s actual usage, Shanghai ANTS recommended an economical model to the customer, HD2016, with an accuracy of 0.08mm, mainly used in the steel structure processing industry, for rough machining, the accuracy is not high, but if ANTS engineers go to the customer’s site for debugging, the processing accuracy can reach the 0.06mm required by the customer.

CNC drilling machines are mainly used for drilling, reaming, chamfering and other processing. Mainly used in automobile, mold, shipbuilding, aerospace, and engineering machinery industries, especially suitable for hardware parts with multiple holes that need to be processed.

|

Workpiece drawing processed by HD2016 |

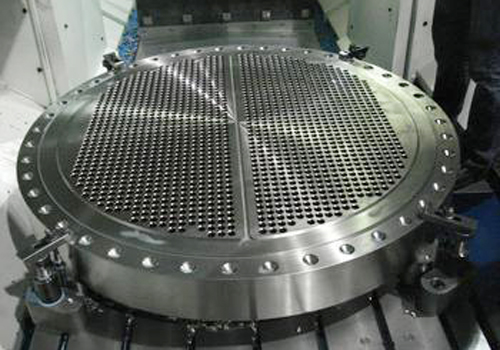

Workpiece drawing processed by PM3030 |

|

|

|

|

|

|

|

|

At present, the customer is still studying the two solutions provided by the Shanghai ANTS team. I believe that with the help of the Shanghai ANTS technical team, the customer’s problem can be solved quickly. Shanghai ANTS is determined to bring high-quality Chinese-made equipment Promote it to the world and hope to become a brand that customers absolutely trust!

Please contact the Shanghai ANTS team if you need any support!