|

|

The processing of CNC lathes for automobile door prototypes usually involves the following key steps:

Prototype production: The prototype of the door is produced using CNC lathes. The commonly used material is ABS sheet. For some specific parts, such as dials, pull rods, etc., POM materials may be selected.

Mold production: After the prototype is completed, a silicone mold is usually made. This step is to be able to replicate more prototype models through the mold in the future.

Prototype model production:

Injection: The PU resin Hei-cast8150 is injected into the mold by vacuum injection to produce a prototype model.

Post-processing: Including grinding, splicing, painting, etc., to ensure that the appearance of the prototype model is consistent with the actual door.

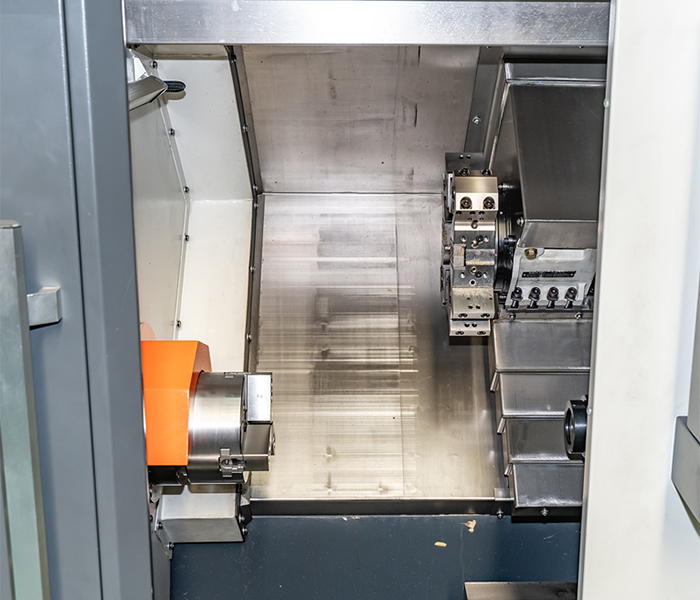

In addition, if it is a larger product such as the front and rear bumpers or front and rear doors of a car, sometimes a CNC lathe is used to make a manual prototype first, and then a low-pressure infusion process is used to make it. The low-pressure injection process is suitable for products with larger volumes. Since the precision requirements for the products are not particularly high, the TCK36A High Accuracy Auto Slant Bed CNC Lathe is used to achieve a processing accuracy of ±0.005mm.

|

|

In summary, the processing of car door prototypes is a complex process that combines multiple technologies and materials. It is necessary to select the appropriate processing method according to specific design requirements and functional requirements. Welcome to consult SHANGHAI ANTS MACHINE EQUIPMENT CO.,LTD!

Keywords: CNC lathe, CNC slant lathe, CNC lathe automotive industry application