Carbide milling cutters are usually cutting tools made of tungsten-cobalt alloy, tungsten carbide and other metal materials. They have the characteristics of high hardness, high strength, wear resistance, and high temperature resistance. Carbide milling cutters have a wide range of applications.

1. Aviation field: Carbide milling cutters can be used in the processing of aviation parts such as aircraft, spacecraft and engines, such as reducers, bearings, compressor impellers and transmission gears, etc.

2. Automobile field: Carbide milling cutters can be used for processing automobile engines, chassis, transmissions, clutches and other parts, such as radiators and cylinder heads, etc.

3. General machinery: In general machinery processing, shaft holes, flat surfaces, outer circles, etc. can be processed. The cutting effect of carbide milling cutters is very outstanding.

4. Mold processing: Carbide milling cutters can also be used for casting and plastic mold manufacturing, such as various plastic parts, electronic product casings such as TVs, computers and mobile phones, etc.

Recently, Shanghai ANTISHICNC received an inquiry from a Brazilian company that specializes in making cutting tools. The customer mainly makes some 1-12mm standard carbide milling cutters, as well as some non-standard milling cutters. The customer contacted us online. After understanding the customer’s processing needs and drawings in detail, we recommended the C818 Mini 5-axis 5-linkage CNC tool grinder. This grinder is based on the concept of the German 5-axis CNC tool grinder and the actual practice of the designers. Designed based on operational experience and communication at tool production sites. It is reflected in practicality, economy, operation, maintenance, stability and efficiency.

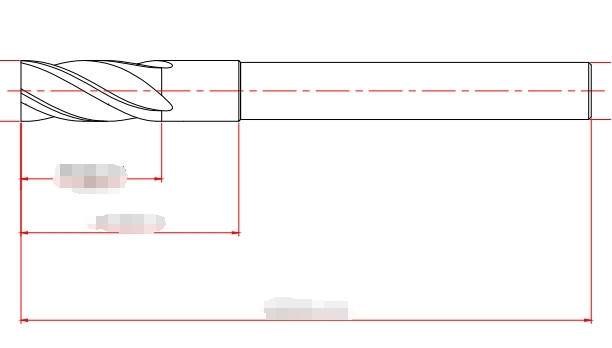

Products produced by the client company

|

|

|

|

|

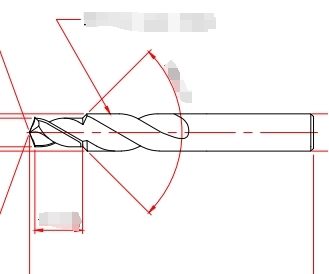

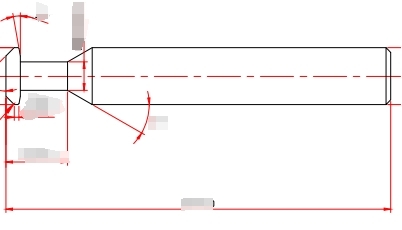

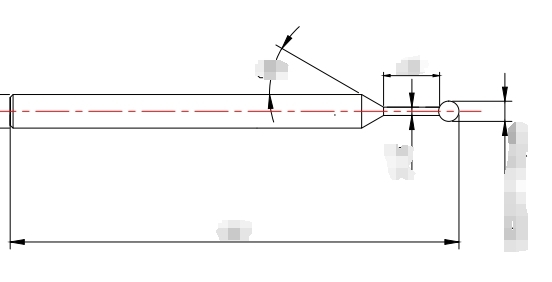

Customers tools drawing |

|

|

ANTISHICNC C818 series 5 axis cnc tool grinder |

|

|

|

|

|

The C818 series tool grinder has a clamping range of 3~32mm and a tool processing range of 1~32mm. It can also be equipped with an optional automated manipulator to efficiently and perfectly meet customers’ processing needs. The following are the technical parameters of C818 Mini Power that we recommend based on customer requirements:

| Model | C818 Mini Power(ANTISHICNC brand) |

| X axis | CNC 5 axis linkage linear axis, Taiwan SYNTEC servo motor drive, power 3.1KW (absolute value) |

|

|

Travel: 600mm; CNC system 0.0001mm, programming and wheel minimum resolution 0.001mm, THK lead screw B IF32-C3, guide SRG 35-P repeated positioning accuracy: 0.003mm |

| Y axis | CNC 5 axis linkage linear axis, Taiwan SYNTEC servo motor drive, power 3.1KW (absolute value) stroke: 330mm; CNC system rating 0.0001mm, programming and hand wheel minimum feed resolution 0.001mm, THK leadscrew B IF32-C3, guide SRG-P repeat positioning accuracy: 0.003mm |

| Z axis | CNC 5 axis linkage linear axis, Taiwan SYNTEC servo motor drive, power 3.1KW (absolute value) stroke: 270mm; CNC system rating 0.0001mm, programming and hand wheel minimum feed resolution 0.001mm, THK lead screw B IF32-C3, guide SRG 35-P repeated positioning accuracy: 0.003mm |

| A axis | CNC 5-axis linkage workpiece rotating shaft, DD Servo direct drive, Power 0.879KW rated TR=28Nm(7.5A), maximum TM=56Nm(16.5A), separation accuracy: ± 2 corner seconds (0.0005 degrees), Rated rotation: 300rpm, maximum rotation: 400rpm, CNC system separation rate: 0.0001 mm, Programming and hand wheel minimum feed resolution 0.001 degrees, Infinite rotation, dividing head body: radial beating: 0.001-0.005mm end beating: 0.001-0.005mm rotary encoder: Renishaw, UK |

| B axis | CNC 5-axis linkage tray rotating shaft, DD Servo direct drive, Power 0.942KW (7.5A) rated TR=120Nm(6.8A), maximum TM = 380 Nm (27A), separation accuracy: ± 2 corner seconds (0.0005 degrees), rated revolutions: 50rpm, maximum revolutions: 100rpm, numerical control system differentiation rate: 0.0001m m, Programming and hand wheel minimum feed resolution 0.001 degrees. The circumference is rotated to 360 degrees, -180 degrees + 180 degrees rotary positioning accuracy: 4arc-sec rotary.encoder: Renishaw, UK |

| Fast moving speed of X.Y.Z | 7.5 m/min |

| The minimum workpiece diameter to clamp | 3mm |

| The maximum workpiece diameter to clamp | 20mm (SUHUNK SK50-20, maximum clamp diameter: 20mm) |

| The maximum workpiece length to clamp | 200mm |

| Main grinding minimum workpiece diameter | 1mm |

| Main grinding maximum workpiece diameter | 12mm |

| Maximum blade port length for main grinding | >100MM |

| Maximum workpiece weight for main grinding | 5kg |

| The blade handle form | SCHAUBLIN W25 or BT50 SK50-20 / 15 (for Customer Choice) |

| Straight resolution | 0.001mm |

| Line repeat positioning accuracy | 0.003mm |

| Rotation resolution | 0.001mm |

| Rotational repeat positioning accuracy | 0.001 degrees |

| Spindle power | 12 kW permanent magnet constant torque electric spindle |

| Sand wheel rod form | HSK50F-31.75mm, or 20mm |

| Sand wheel diameter | 75~150mm |

| Sand wheel spindle speed | 1000 to 8000 rpm stepless adjustable: drive |

| Machine weight | About 4,000 kg |

| Total power | ≤22.5kw |

If your company also has the same processing needs, please contact us. You can provide processing drawings, and our very professional engineers will comprehensively evaluate the drawings and recommend you a suitable machine based on the processing material, workpiece size, and processing requirements.