In modern manufacturing, precision and efficiency are key—and CNC turning lathes play a crucial role in achieving both. But what exactly is a CNC turning lathe, and how does it work?

we’ll cover:

1. What a CNC turning lathe is

2. How it works

3. Key components

4. Advantages over manual lathes

5. Common applications

6. Choosing the right CNC lathe

What is a CNC Turning Lathe?

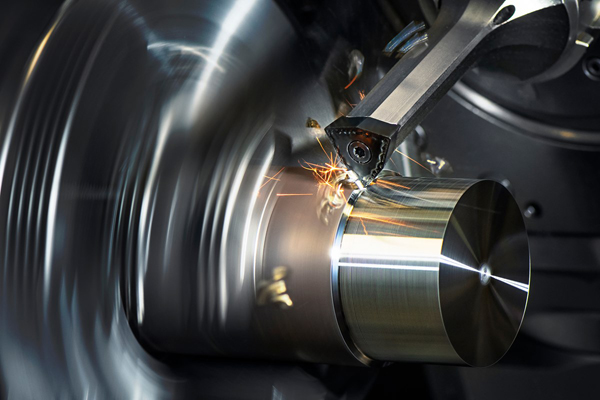

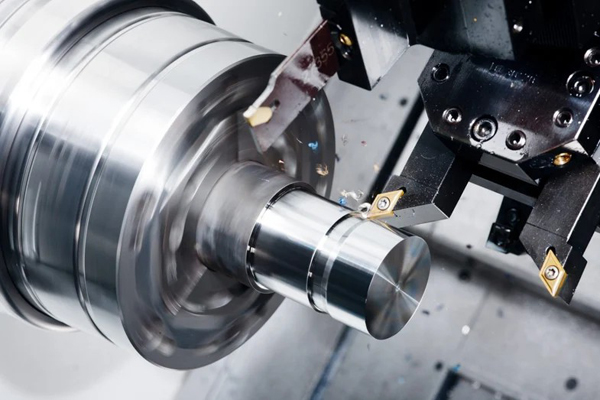

A CNC (Computer Numerical Control) turning lathe is a machine tool that rotates a workpiece while a cutting tool removes material to create cylindrical parts. Unlike manual lathes, CNC lathes are automated, following programmed instructions for high-precision machining.

These machines are widely used in industries like aerospace, automotive, medical, and electronics to produce components such as shafts, bushings, and threaded parts.

How Does a CNC Turning Lathe Work?

Design & Programming – A CAD (Computer-Aided Design) model is created, then converted into CNC code (G-code) using CAM software.

Setup – The workpiece is clamped into the chuck, and tools are loaded into the turret.

Machining – The CNC system controls spindle speed, tool movement, and cutting depth to shape the material.

Finishing – Additional operations like drilling, grooving, or threading may be performed.

Completion – The finished part is removed, ready for inspection or further processing.

Key Components of a CNC Turning Lathe

Headstock – Houses the spindle and motor, rotating the workpiece.

Chuck – Holds the workpiece in place (3-jaw or 4-jaw chucks are common).

Turret – Holds multiple cutting tools and rotates to switch between them.

Tailstock – Supports long workpieces for stability.

Control Panel – Where operators input and adjust CNC programs.

Bed – The machine’s base, providing rigidity and stability.

Coolant System – Reduces heat and prolongs tool life.

Advantages of CNC Turning Lathes Over Manual Lathes

1. Higher Precision – CNC machines achieve tolerances within ±0.001 inches or less.

2. Faster Production – Automation reduces cycle times and increases output.

3. Consistency – Every part is identical, reducing human error.

4. Complex Geometries – CNC lathes can produce intricate shapes that manual lathes cannot.

5. Reduced Labor Costs – One operator can manage multiple machines.

Common Applications of CNC Turning Lathes

CNC turning lathes are used to manufacture parts such as:

Automobile manufacturing: processing engine parts, transmission shafts, etc.

Aerospace: production of high-precision turbine blades and landing gear parts.

Medical equipment: manufacturing artificial joints, surgical instruments and other precision parts.

Electronics industry: processing metal casings and precision parts of mobile phones and computers.

Mold manufacturing: used for the processing of injection molds and stamping molds.

How to Choose the Right CNC Turning Lathe

When selecting a CNC lathe, consider:

Workpiece Size – Ensure the machine can handle your part dimensions.

Spindle Speed – Higher RPMs allow for finer finishes on metals.

Number of Axes – 2-axis for simple parts; multi-axis (e.g., 5-axis) for complex shapes.

Tool Capacity – More tools mean fewer manual changes.

Automation Options – Bar feeders and robotic arms increase efficiency.

Brand & Support – Choose reputable manufacturers with good service.

A CNC turning lathe is an essential machine for precision manufacturing, offering speed, accuracy, and repeatability unmatched by manual methods. Whether you’re producing automotive parts, medical devices, or industrial components, investing in a CNC lathe can significantly enhance productivity and quality.

Looking for the right CNC lathe for your needs? Consult with a trusted supplier to find the best machine for your applications.

Optimized Keywords: CNC turning lathe, CNC lathe machine, CNC turning process, precision machining, CNC turning applications, best CNC lathe