radial drilling machine is mainly used for reaming, drilling countersunk holes, countersinking end face, reaming, tapping, etc. It is commonly used in machinery manufacturing and repairing factories to process holes of medium and small workpieces.

Recently ANTISHICNC received a lot of customer inquiries: why radial drilling tapping diameter is smaller than the diameter of the hole? So here is a unified answer:

1:Ensure thread quality: When tapping, the tap mainly forms threads on the workpiece through cutting and squeezing action. If the tapping diameter is the same as the drilling diameter, due to the extrusion effect of the tap, it will lead to a smaller diameter of the threaded hole, or even incomplete threads, unclear tooth shape and other problems. While the tapping diameter is smaller than the drilling diameter, it can provide enough space for the formation of threads to ensure the quality and accuracy of threads.

2:Reduce tap wear: During the tapping process, the tap will generate greater friction and cutting force with the workpiece. If the tapping diameter is the same as the drilling diameter, the cutting edge and side of the tap will be in direct contact with the hole wall, which increases the wear of the tap. While the tapping diameter is smaller than the drilling diameter, it can reduce the contact area between the tap and the hole wall, reduce the wear of the tap, and extend the service life of the tap.

3:Easy chip removal: Tapping will produce chips, if the tapping diameter is the same as the drilling diameter, the chips are easily blocked in the threaded hole, affecting the smooth progress of tapping. The tapping diameter is smaller than the drilling diameter, which can provide a larger space for the discharge of chips and facilitate chip removal, avoiding the accumulation of chips leading to tap breakage or threaded hole damage.

4:Improve tapping efficiency: Appropriate reduction of tapping diameter can reduce the difficulty of tapping, reduce the torque and power required for tapping, thus improving the efficiency of tapping.

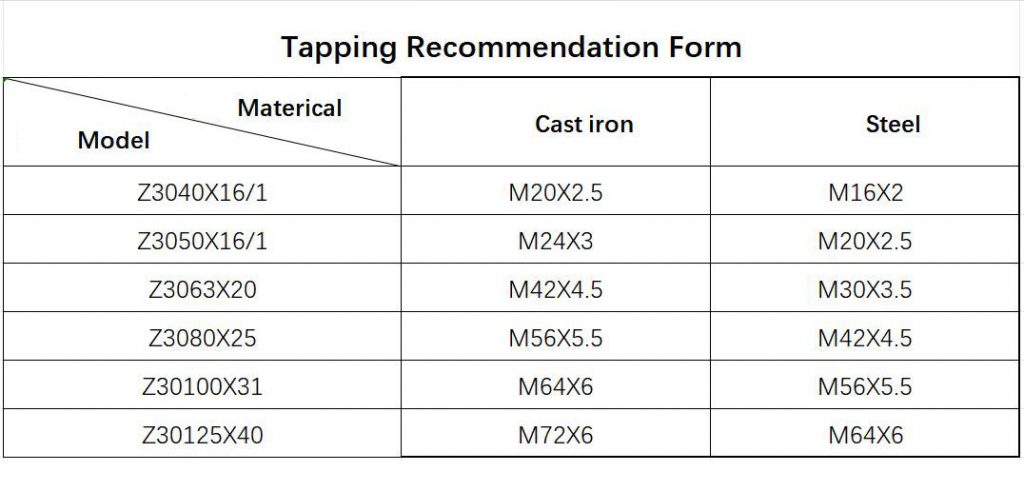

It should be noted that the difference between the tapping diameter and the drilling diameter should be determined according to the specific workpiece material, thread specifications and processing requirements. Generally speaking, the difference should not be too large or too small, too large may lead to insufficient thread strength, too small may increase the difficulty of tapping and tap wear. In actual processing, the appropriate tapping diameter and drilling diameter should be selected according to experience and process requirements to ensure tapping quality and processing efficiency.

If you need radial drilling machine or have similar processing needs, Welcome to consult Shanghai ANTISHICNC.We have rich experience in manufacturing and processing radial drilling machine, and can provide you with professional technical support.Please send your inquiry or quesitons to contact@antsmachine.com for instant feedback.

Tags: Radial drilling machine,drilling hole,Tapping,vertical drilling machine