|

|

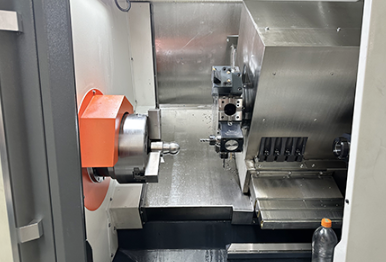

As shown in the figure, the size of the car headlight prototype is 25cm*28cm*30cm, and the required processing accuracy is 0.01mm. The material is aluminum. Shanghai ANTISHICNC engineers recommend using TCK50AY CNC Slant Bed Turning-milling lathe machine for processing. The headlight frame prototype is mainly used to make samples or models for verifying the design of the headlight frame during the design and development of automobile lamps. These prototypes are important physical prototypes used to evaluate the practicality, structural strength, assembly compatibility of the design, and to conduct related functional tests. The following are the general steps for processing the headlight frame prototype:

Design stage: The designer first uses computer-aided design (CAD) software to draw the design of the headlight frame. This includes determining key parameters such as the size, shape, support structure and connection points of the headlight frame.

Material selection: Select the appropriate material according to the purpose and needs of the prototype. Commonly used materials include plastics (such as ABS, PC), metals (such as aluminum alloys), or other composite materials.

Installation and clamping: Install the raw material on the chuck of the CNC lathe to ensure that it is firmly installed and accurately positioned. Use a suitable fixture to clamp the raw material to prevent movement or deformation during processing.

Roughing and finishing of CNC lathe machine

1.Choose appropriate roughing tools, such as carbide tools, for roughing. The purpose of roughing is to quickly remove most of the material and approach the final shape and size. When finishing, choose high-precision carbide tools or diamond tools.

2.Set appropriate cutting parameters for CNC lathemachine, such as cutting speed, feed rate, and cutting depth. During roughing, pay attention to the wear of the tool and replace the tool in time to ensure the processing quality.

|

|

TCK50AY CNC Slant Bed Turning-milling lathe processing features

1.According to the design requirements of the headlights, process features such as holes, threads, chamfers, etc. Special tools such as drills and taps can be used for processing.

2.For complex curved surfaces, the multi-axis linkage function of the CNC turning center can be used for processing to obtain smoother and more precise surfaces.

Keywords: CNC lathe, CNC slant bed lathe, CNC Turning milling Lathe Machine, CNC lathe for automotive industry