What is a bandsaw machine?

Bandsaw machine is a cutting machine widely used in industrial production, mainly used to cut various materials, including wood, metal, plastic, etc. It achieves the cutting function through a sharp toothed blade and a platform that supports and moves the raw material.

Classification of bandsaw machines

bandsaw machines can be classified into several categories based on their design, functionality, and application. Here are some common classifications:

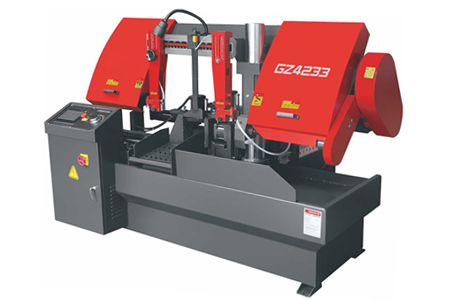

Metalworking Bandsaws: These bandsaws are designed for cutting metal and are commonly used to cut metal tubes, bars, and profiles.

Circular Saw Machine: Circular saws are particularly suitable for cutting metal materials such as steel, copper, aluminum, etc., achieving 90o or 45o cutting, with smooth cut surfaces and no burrs. They are widely used in industries such as gears, automobiles, and precision forging.

Horizontal Straight Cutting Bandsaws: which are designed for straight cuts in larger work-pieces made of steel, cast iron and other metals. For batch sawing of small and medium-sized bars, tubes and profiles, and can be adapted to sawing of various ferrous materials. It has the characteristics of high cutting efficiency, energy saving, narrow kerf, energy saving and material saving, and simple operation.

It is widely used for sawing various metal materials in various industries such as electromechanical, metallurgy, automobiles, bridges, and ships.

Horizontal Mitre Cutting Bandsaws: For high precision metal cutting, is the ideal equipment for the industrial and mining enterprises and small workshops, use is very extensive.Cuts almost anything that you can throw at it, including many different shapes and profiles of metal.Variable cutting speeds allow you to fine-tune the saw for better cut quality.

Vertical bandsaws: These bandsaws are designed to cut materials vertically, often used for sawing small-sized steel plates, bars, etc. It has the advantages of narrow sawing, material saving, energy saving, high sawing precision, convenient operation and high production efficiency.

Specialty bandsaws: These bandsaws are designed for specific applications, such as cutting curved or irregular shapes, or cutting materials with unique properties.

How does a bandsaw machine work?

Bandsaw machine is a machine tool that drives a band saw blade to cut workpieces through an active saw wheel. In order to ensure that the band saw blade does not slip during the sawing process, the band saw blade needs to be pre-tightened before normal operation; during sawing, the motor drives the active saw wheel to rotate. Due to the effect of friction, the active saw wheel will drive the horizontal section of the band saw blade to move at a certain cutting speed. At the same time, the entire saw frame moves downward at a certain feed speed under the drive of the feed cylinder, thereby completing the sawing of the workpiece.

Development trend of bandsaw machines

As metal sawing processing gradually shifts from cutting-based processing to fine processing, higher requirements are placed on the design technology and manufacturing level of band saws, and band saws are gradually developing towards high-end products. The development trend of international high-end band saws is mainly reflected in the following aspects.

(1) Further improvement in sawing accuracy. Using advanced variable frequency motor drive, precision ball screw transmission and optical positioning method, equipped with a servo-controlled hydraulic system, the computer automatically monitors the sawing process of the metal band saw online. The saw blade speed, feed speed and clamping force can be set and optimized at will, thereby ensuring the processing accuracy of the metal band saw. At present, the error of 100mm cutting height is 0.1mm, which is expected to be further improved.

(2) Advanced sawing force control technology. One of the key technologies of metal sawing is the control of the sawing force, which ensures the stability of the saw blade during sawing, reduces vibration, and improves the sawing accuracy and the life of the saw blade.

(3) Sawing processing is more efficient. Improving sawing efficiency, especially improving the sawing efficiency of thick materials and hard metals, and avoiding sawing from becoming the bottleneck of the entire production line, has always been the focus of attention in the field of sawing and sawing machine technology.

(4) Expanding sawing capacity. At present, sawing machines can saw solid square materials up to 2.5mx2.0m, and giant vertical band saws can saw plates and bars up to 10m long.

(5) CNC and networking. The cutting process of large workpieces often lasts for several hours. In order to ensure the production conditions of one person and multiple machines and improve the accuracy and efficiency of sawing processing, CNC sawing process is imperative. Networked production, remote diagnosis and maintenance are the development trends of CNC machine tools, and CNC saws are no exception. Networked production can connect the metal band sawing process with other links, improve productivity, and facilitate enterprises to achieve efficient and unified management of various links.

(6) Remote diagnosis and maintenance. Remote diagnosis and maintenance are the result of economic globalization. Metal band saws can provide rapid equipment maintenance across countries and regions.